Blade casting die, application of blade casting die and blade forming method

A technology for casting molds and blades, applied in casting molding equipment, molds, mold components, etc., can solve the problems of coarse grains on the surface of cooling speed, poor surface finish, insufficient pouring, etc., and achieve less surface defects and better blade quality. , block reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

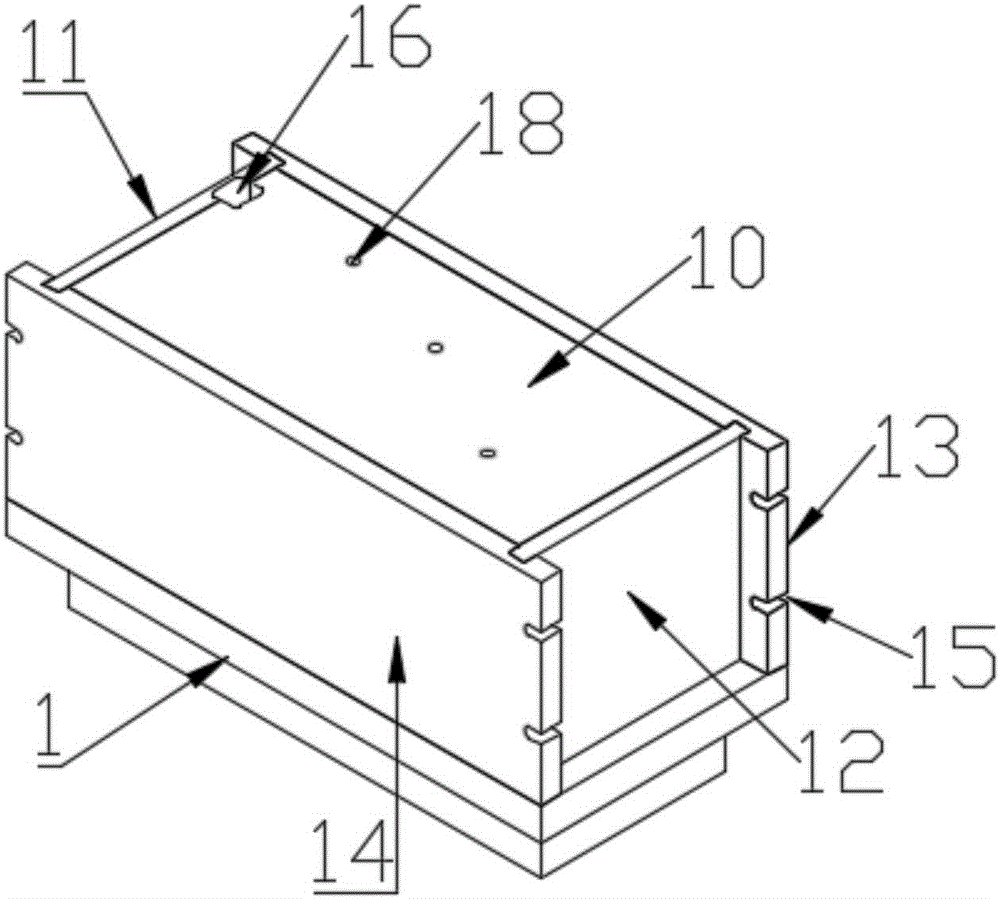

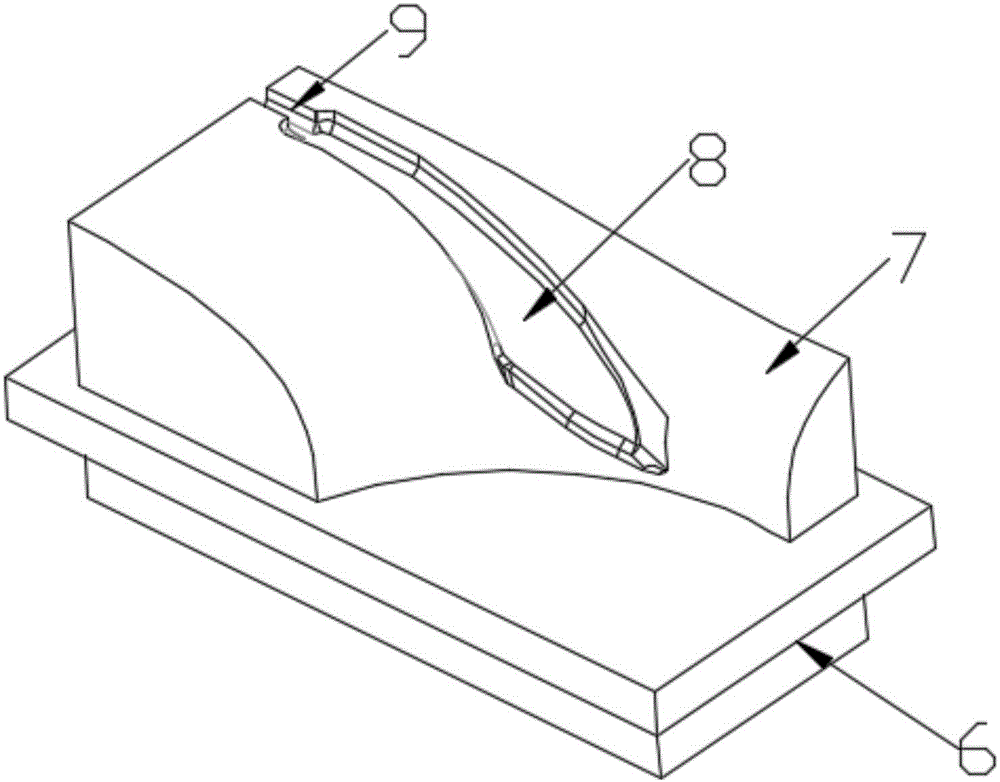

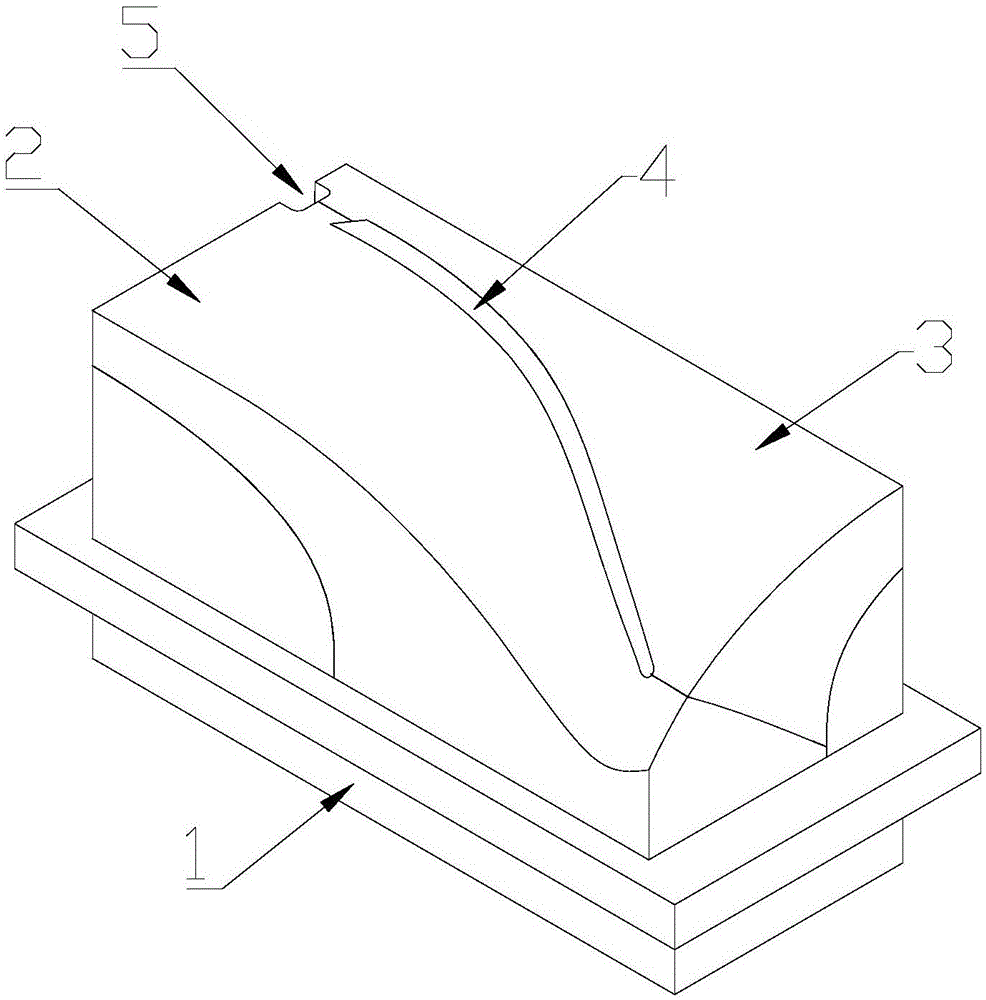

[0047] like Figure 1-Figure 3As shown, a casting mold for a blade includes an upper mold and a lower mold 1 which are arranged correspondingly up and down, and a first groove 8 for forming a three-dimensional distortion of the lower edge of the blade is provided at the joint between the lower mold 1 and the upper mold; the upper mold It includes the first upper mold assembly 2 and the second upper mold assembly 3 which are arranged in front and back correspondingly, the two ends of the butt joint surfaces of the first upper mold assembly 2 and the second upper mold assembly 3 are bonded, and the first upper mold assembly The middle part of part 2 and the second upper mold assembly 3 has a hollow space 4 for forming the main part of the blade, which is used for molding the thin-walled part of the main body of the blade, wherein the surface of the hollow space is twisted and extended along the surface of the blade in three dimensions; the upper part of the upper mold is connecte...

Embodiment 2

[0064] like Figure 5 and Figure 7 As shown, one end of the first upper die assembly 2 and the second upper die assembly 3 does not fit, and a triangular mold 19 is set at the corner of the first upper die assembly 2 and the second upper die assembly 3 , the triangular mold 19 includes the first triangular mold assembly 20 and the second triangular mold assembly 21 correspondingly arranged before and after, and the first triangular mold assembly 20 and the second triangular mold assembly 21 fit together; the triangular mold is positioned at the gate and constitutes a part of the runner, which is convenient for removing the gate and demoulding after the low-melting alloy is solidified.

[0065] The outer boundary of the triangular mold 19 is provided with a runner 5 connected to the first groove 8 of the lower mold 1 near the third limiting plate 13; pouring is carried out at the runner 5, and the casting melt flows out of the mold along the runner. The first groove on the l...

Embodiment 3

[0067] A method for forming a blade, comprising the following steps:

[0068] Step 1: cleaning the surfaces of the component parts of the blade casting mold, assembling the blade casting mold for use, and coating the inner surface of the blade casting mold with a release agent;

[0069] Step 2: Weigh the casting raw materials according to the set requirements, and clean the dust on the surface of the casting raw materials;

[0070] Step 3: Put the blade casting mold in the dryer to preheat, and use the temperature measurement module to monitor the temperature of the blade casting mold until the required temperature is set to stop preheating;

[0071] Step 4: Heat the casting raw material to melt it to form a casting raw material solution, use the temperature measurement module to monitor the temperature of the casting raw material solution until the required temperature is set and stop heating;

[0072] Step 5: removing impurities on the surface of the casting raw material so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com