Grinding device for grinding center hole

A grinding device and center hole technology, which is applied in the direction of grinding devices, grinding machine tools, work carriers, etc., can solve the problems of low quality of center holes, reduce the economic benefits of producers, and low center hole precision, and achieve high processing accuracy and safe use Good performance and operation stability, reasonable device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

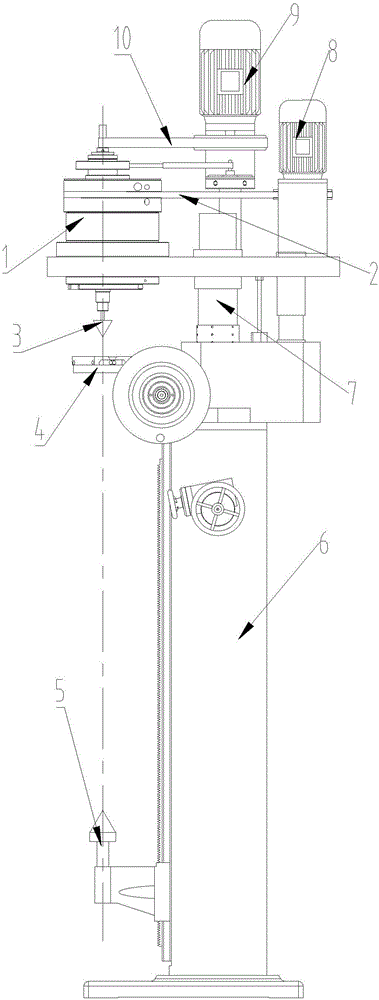

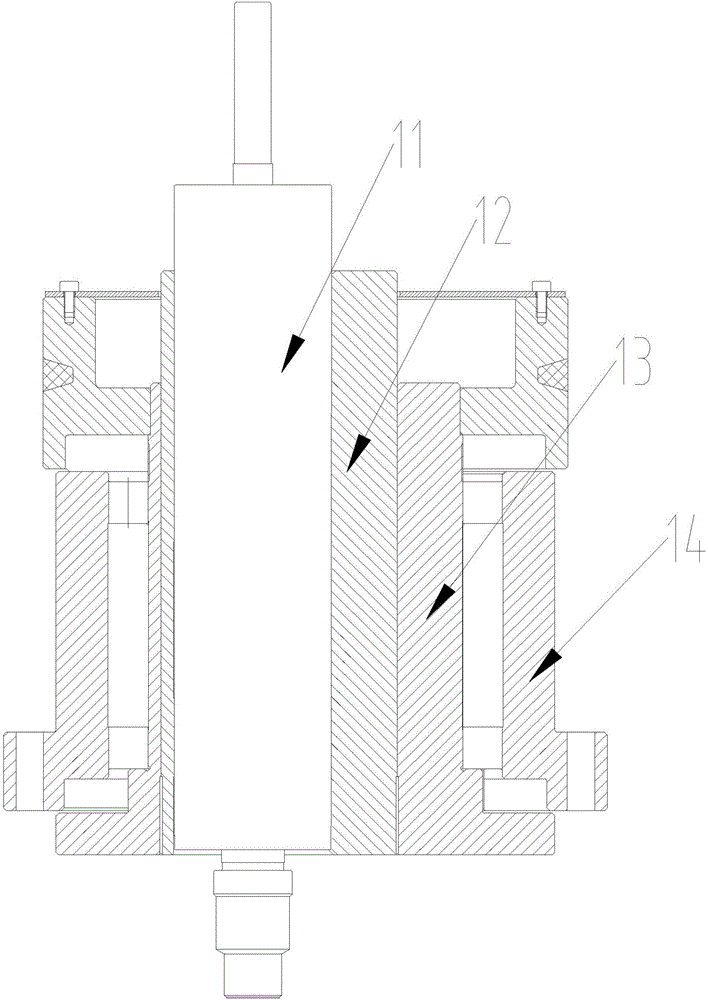

[0013] see Figure 1-2 , a grinding device for grinding a central hole, comprising a main shaft assembly 1, a belt 2, a grinding wheel 3, a centering locking device 4, a tailstock 5, a bed 6, a guide post 7, a motor and a high-speed belt 10, and the motor includes Geared motor 8 and high-speed variable-frequency motor 9, main shaft assembly 1 includes high-speed main shaft 11, small eccentric shaft 12, large eccentric shaft 13 and main shaft housing 14, the outer sheath of high-speed main shaft 11 is provided with small eccentric shaft 12, small eccentric shaft 12 The outer sleeve is provided with a large eccentric shaft 13, the main shaft housing 14 is located outside the large eccentric shaft 13, a tailstock 5 is provided on one side of the bed 6, and the centering locking device 4 is installed on one side of the top of the bed 6 and fixed The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com