Train overload detection system and method

The technology of a detection system and detection method, which is applied in the field of on-board detection of rail vehicles, can solve the problems of potential safety hazards in train operation and failure to reflect the actual load of trains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

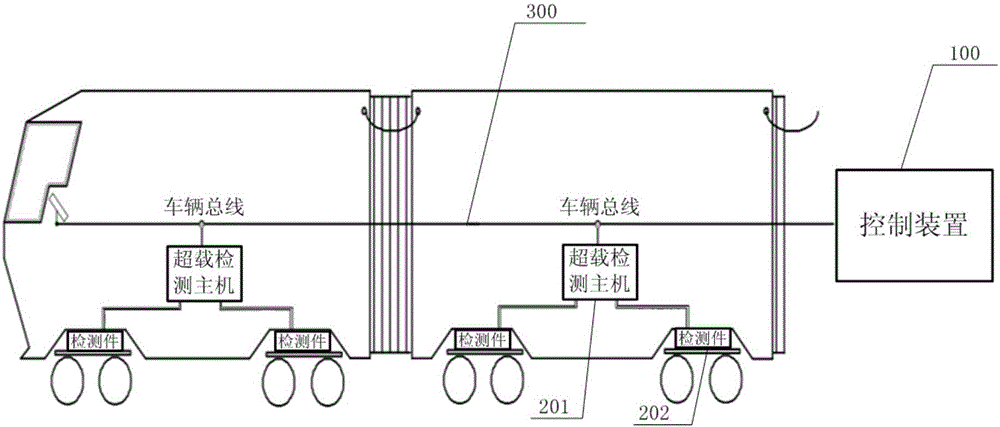

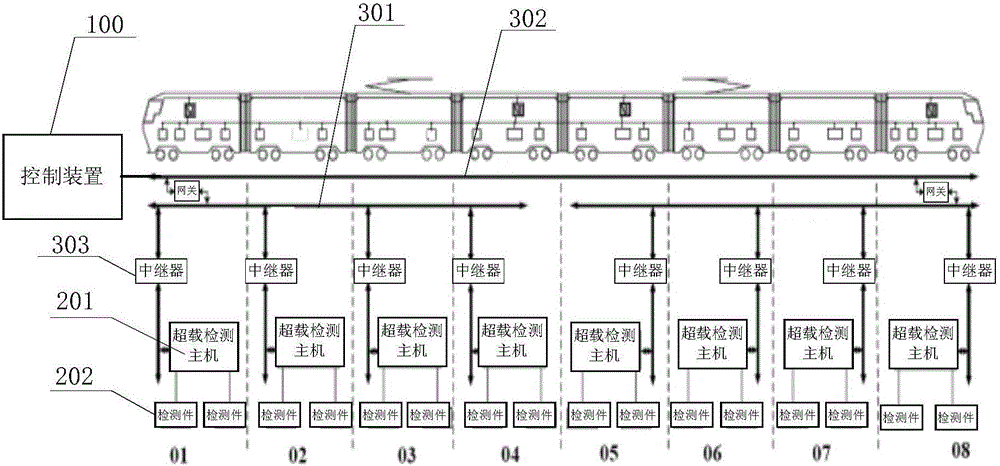

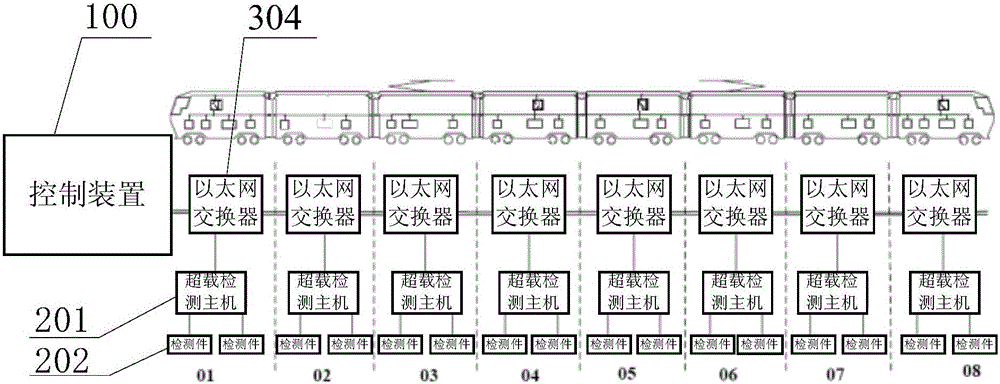

[0055] figure 1 It is a partial structural diagram of the train overload detection system of the present invention, figure 2 It is a schematic diagram of the connection between the overload detection host and the control device in the train overload detection system of the present invention, image 3 It is another schematic diagram of the connection between the overload detection host and the control device in the train overload detection system of the present invention, such as Figure 1-3 As shown, the train overload detection system includes: an overload detection device arranged in each carriage and a control device 100 connected to each overload detection device, wherein, figure 1 Only two carriages are shown in figure 2 8 cars are shown in, where, in this embodiment, an overload detection device is provided in each car, and the overload detection device in each car is connected to the control device 100 through the vehicle bus 300.

[0056] Wherein, the overload detection d...

Embodiment 2

[0074] Figure 5 It is a schematic flow chart of the train overload detection method of the present invention. In this embodiment, Figure 5 As shown, the method includes the following steps:

[0075] Step 501: A detection component arranged on the air spring pipeline of each car bogie detects the load capacity of the car.

[0076] In this embodiment, in order to detect the load capacity of each car, a detection element 202 is provided on the bogie air spring pipeline of each car. The detection element 202 detects the load capacity of the car and sends the detected load capacity. An overload detection host 201 is provided in the compartment.

[0077] Step 502: The overload detection host set in each car obtains the load status of the car according to the load detected by the detection part and the preset load threshold range and sends the load and load status to the control device, where the load status includes Safe state, biased state and overweight state.

[0078] In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com