Aluminum-foil paper cutting, conveying, disinfecting and drying device

A drying device, the technology of aluminum foil paper, applied in the directions of transportation and packaging, sending objects, chemistry, etc., can solve the problems such as the inability of the aluminum foil paper to be fixed, the knife seat is prone to swing and displacement, and the cutting tolerance of the cutting edge is changed. Ease of processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

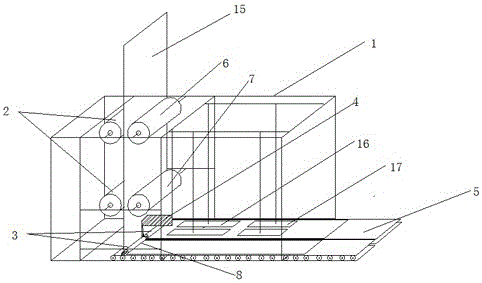

[0032] like figure 1 As shown, said a kind of aluminum foil paper cutting conveying disinfection drying device includes frame 1, drum assembly, cutting edge 4 and aluminum foil paper 15 to be processed, and the drum assembly includes a The transmission roller assembly 2 for vertical transmission at the bottom of the frame 1 is installed under the transmission roller assembly 2 to change the vertical displacement of the aluminum foil 15 into a horizontal displacement steering roller assembly 3; the cutting edge 4 is arranged on the transmission roller assembly 2 and the steering roller assembly 3 Between, the cutting edge of cutting blade 4 faces the moving direction of aluminum foil paper 15 and cuts aluminum foil paper 15; Turning to the bottom of drum assembly 3 is provided with the conveyor belt 5 corresponding to the cut aluminum foil paper 15, and the above conveyor belt 5 The frame 1 is provided with a disinfection device 16 and a drying device 17, and the disinfection d...

Embodiment 2

[0034] According to the above structure, the transmission drum assembly and the cutting blade are further improved.

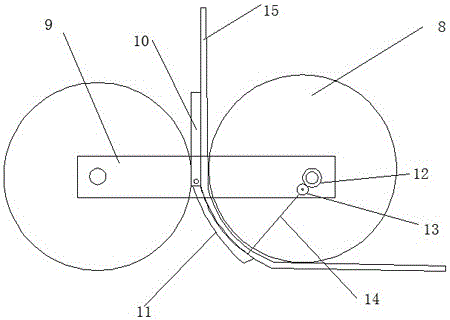

[0035] like figure 1 and figure 2 As shown, said a kind of aluminum foil paper cutting conveying disinfection drying device includes frame 1, drum assembly, cutting edge 4 and aluminum foil paper 15 to be processed, and the drum assembly includes a The transmission roller assembly 2 for vertical transmission at the bottom of the frame 1 is installed under the transmission roller assembly 2 to make the aluminum foil 15 change from vertical displacement to horizontal displacement. Two upper rollers 6, two middle rollers 7 installed in the middle of the frame 1, the middle rollers 7 are located directly below the upper rollers 6, and the aluminum foil paper 15 respectively passes through the gap between the two upper rollers 6 and The gap between the two middle rollers 7 is connected to the steering drum assembly 3; the cutting edge 4 is arranged between the tr...

Embodiment 3

[0037] According to the above structure, the cutting blade and the rotating drum assembly are further improved.

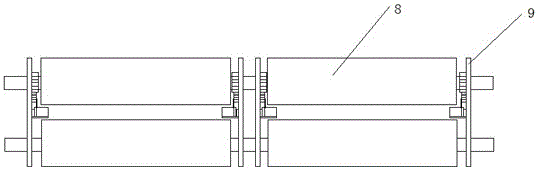

[0038] like figure 1 , figure 2 and image 3As shown, said a kind of aluminum foil paper cutting conveying disinfection drying device includes frame 1, drum assembly, cutting edge 4 and aluminum foil paper 15 to be processed, and the drum assembly includes a The transmission roller assembly 2 for vertical transmission at the bottom of the frame 1 is installed under the transmission roller assembly 2 to make the aluminum foil 15 change from vertical displacement to horizontal displacement. Two upper rollers 6, two middle rollers 7 installed in the middle of the frame 1, the middle rollers 7 are located directly below the upper rollers 6, and the aluminum foil paper 15 respectively passes through the gap between the two upper rollers 6 and The gap between the two intermediate rollers 7 is then connected to the turning roller assembly 3, which includes two lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com