Balanced hoisting device for nuclear power plant steel dome

A technology of balance cranes and nuclear power plants, which is applied in hoisting devices, transportation and packaging, and load hanging components, etc. It can solve the problems of affecting the accuracy of wire ropes, increasing the tension of ropes, and complex structural forms, so as to ensure safety and hoisting Quality, Guaranteed Accuracy and Sensitivity, Effect of Saving Engineering Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

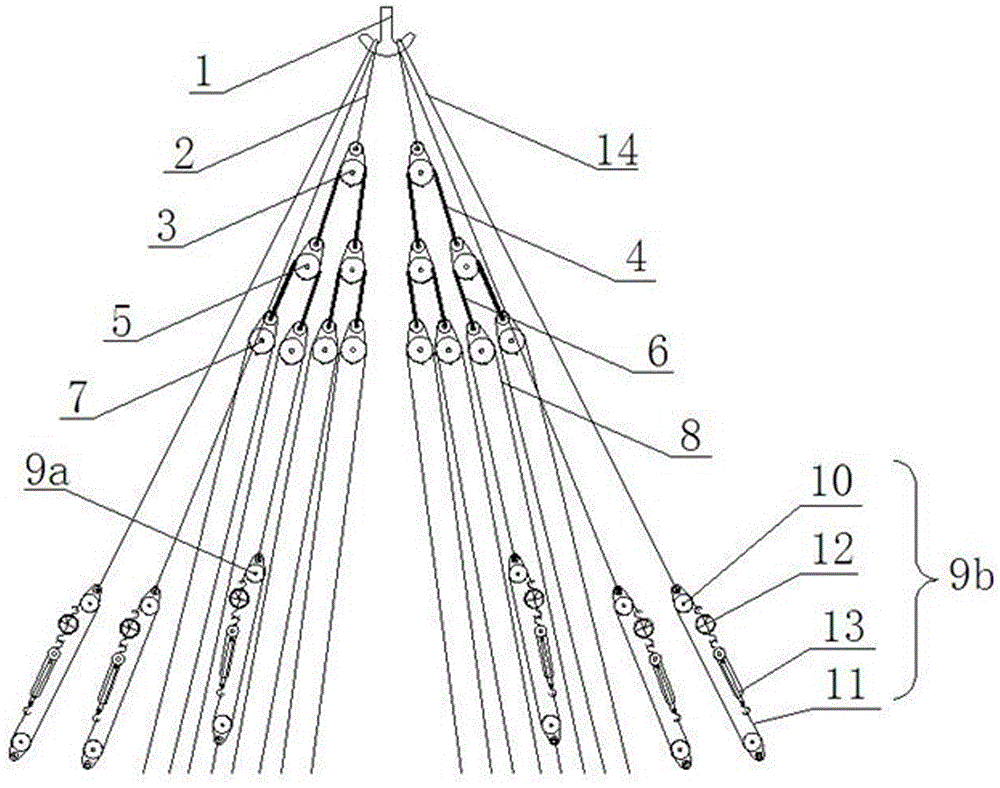

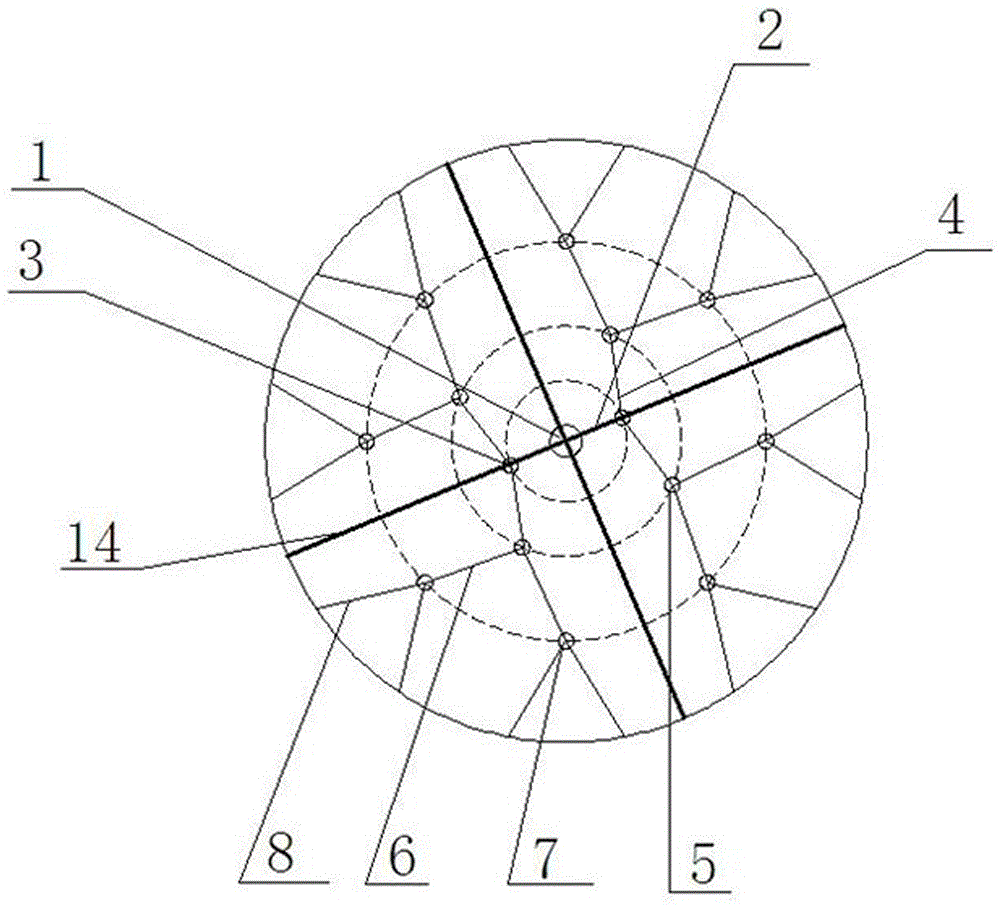

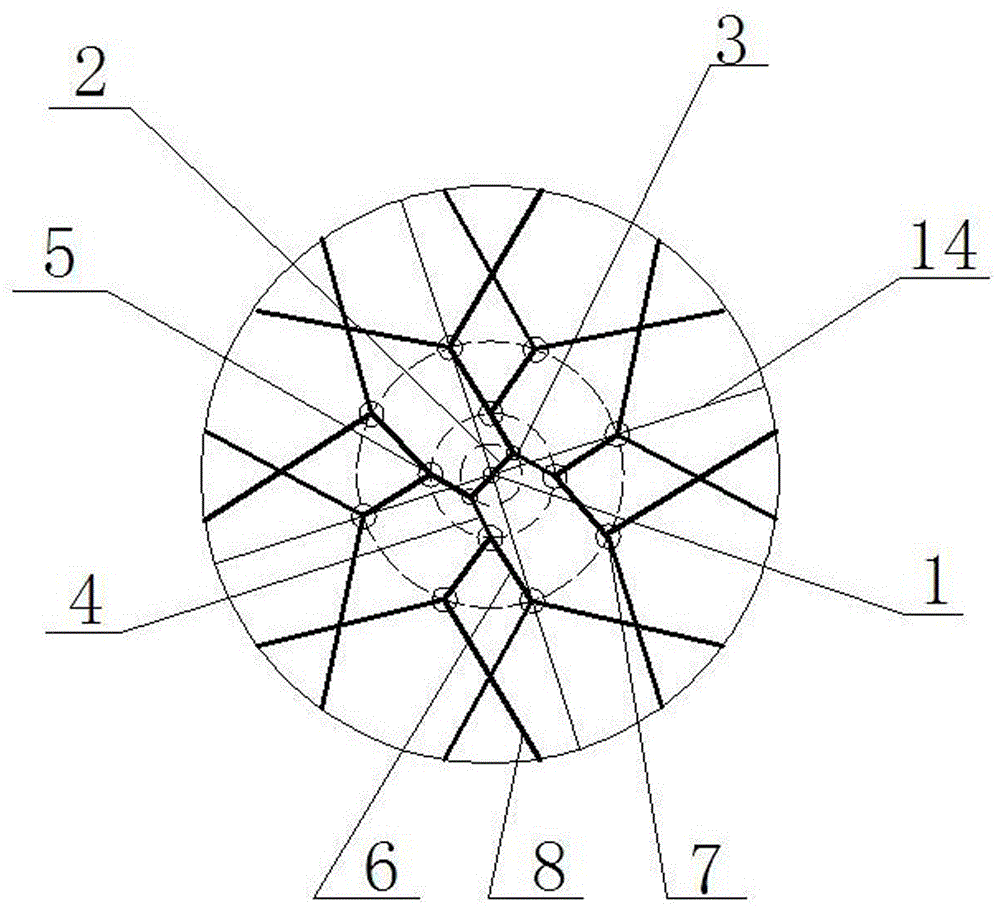

[0049] Embodiment A balanced hoisting device for a nuclear power plant steel dome

[0050] A steel dome balance hoisting device for a nuclear power plant, used in conjunction with lifting machinery,

[0051] Such as Figure 1-9As shown, this embodiment includes a hook 1, a main hoisting wire rope 2, a first layer of balance pulley 3, a first layer of auxiliary hoisting wire rope 4, a second layer of balancing pulley 5, a second layer of auxiliary hoisting wire rope 6, and a third layer of balance Pulley 7, third floor auxiliary hanging wire rope 8, first adjusting device 9a, second adjusting device 9b, adjusting pulley 10, adjusting wire rope 11, dynamometer 12, reverse chain 13, fixed rope 14, and first rope hole 151 , the second rope hole 152 . Generally speaking, it includes a hoisting unit that suspends the dome on the lower end and pulls the dome upwards and can drive the dome to move under the action of a hoist, and a fixing unit that ensures the stability of the dome....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com