Manual hoist with weighing function

A manual hoist and function technology, which is applied to portable lifting devices, hoisting devices, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effects of reducing labor intensity, improving work efficiency, and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

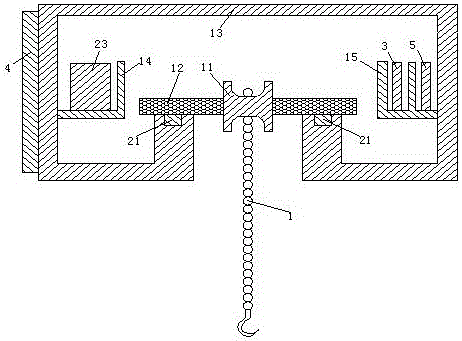

[0022] In this example, if figure 1 As shown, a manual hoist with a weighing function includes a manual hoist body 1, wherein the static pulley 11 of the manual hoist body 1 is rotatably connected to the casing 13 through a rotating shaft 12, and a transmission is provided at the contact position between the casing 13 and the rotating shaft 12. The force conversion system, the force transmission conversion system includes a pressure sensor 11, an amplifying circuit, and an analog-to-digital converter 23, the pressure sensor 21 is installed at the contact between the housing 13 and the rotating shaft 12, and the analog-to-digital converter 23 is installed on the inner side wall of the housing 13 On; this embodiment also includes an information processing system 3 connected to the analog-to-digital converter 23 of the force transmission conversion system, wherein the information processing system 3 is a central processing unit with computing power, and this embodiment also includ...

Embodiment 2

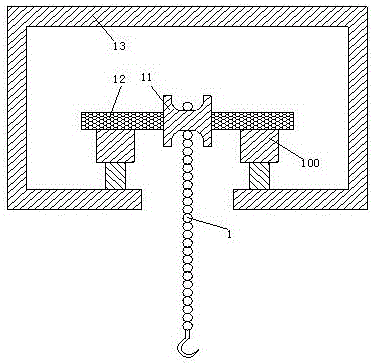

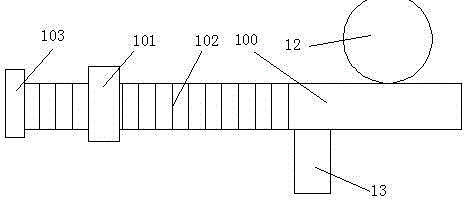

[0026] This embodiment serves as another kind of implementation mode of the above-mentioned embodiment, such as figure 2 , image 3 Shown, in the present embodiment, comprise lever 100, weight 101, adopt the principle of lever, one end of lever 100 is connected with the free end of rotating shaft 12, and the fulcrum of lever 100 is on the shell 13, and the other end of lever 100 is provided with weight 101, and lever 100 is provided with a scale 102 . Using the above method, the user can determine the weight of the goods by observing the scale 102 corresponding to the weight 101 on the lever 100 .

[0027] As a further limitation of this embodiment, a stopper 103 for preventing the weight 101 from falling is provided at the free end of the lever 100 . With the above structure, the weight 101 can be prevented from falling from the lever 100, thereby improving the safety of the present invention.

Embodiment 3

[0029] This embodiment is further improved on the basis of the above-mentioned embodiments. In this embodiment, an A housing 14 and a B housing 15 are installed on the inner wall of the above-mentioned housing 13, wherein the cavity formed by the A housing 14 and the housing 13 The above-mentioned analog-to-digital converter 23 is installed inside, and the above-mentioned structure can be used to protect the analog-to-digital converter 23; the central processing unit is installed in the cavity formed by the B housing 15 itself, and the central processing unit can be protected by using the above-mentioned structure. Further prolonging the service life of the present invention, improving the practicability and safety of the present invention.

[0030] As a specific implementation manner of this embodiment, the upper end surfaces of the A housing 14 and the B housing 15 are not sealed, and the above method is adopted to facilitate the installation, disassembly and connection of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com