A method for preparing isotropic and anisotropic switchable superhydrophobic surfaces

A super-hydrophobic surface, isotropic technology, applied in the process of producing decorative surface effects, manufacturing microstructure devices, decorative arts, etc., can solve the problem of less research on dynamic anisotropy, and improve reusability. Sexual, inexpensive, widely used effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

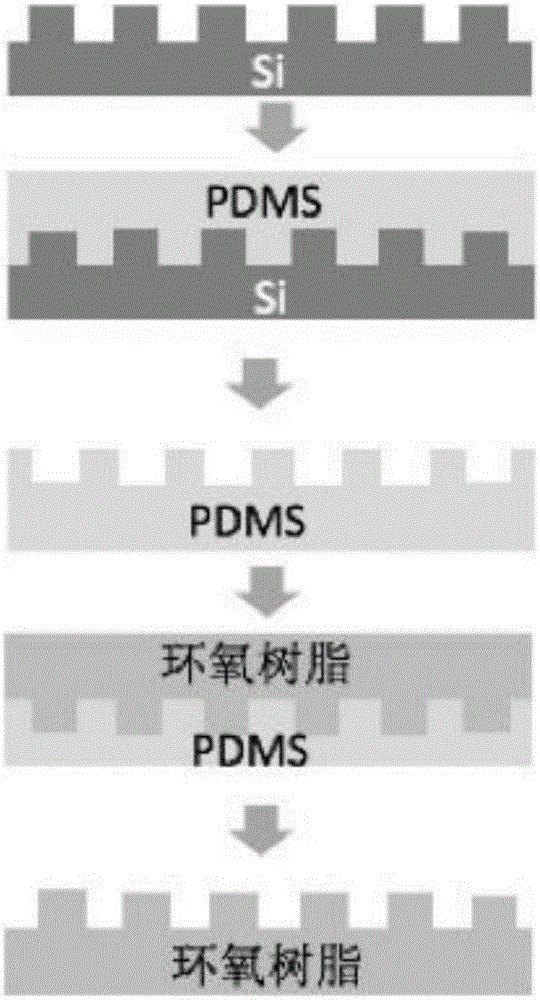

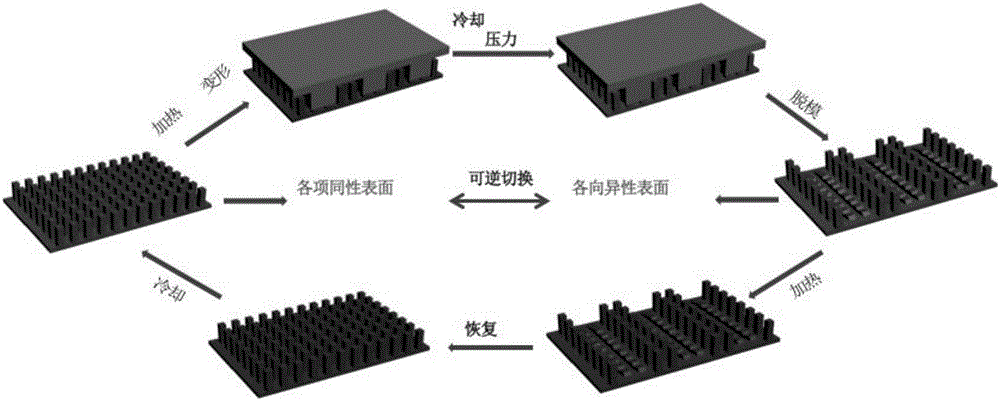

[0039] Specific implementation one: as figure 1 As shown, this embodiment prepares isotropic and anisotropic switchable superhydrophobic surfaces according to the following steps:

[0040] Step 1. Use template method to prepare shape memory epoxy resin microarray

[0041] Preparation of PDMS (Dow Corning 184) intermediate template: The PDMS precursor and curing agent are mixed in a ratio of 10:1, poured on the silicon template and cured at 65-100°C for 2-5 hours, and the PDMS intermediate template prepared by demolding is ready for use.

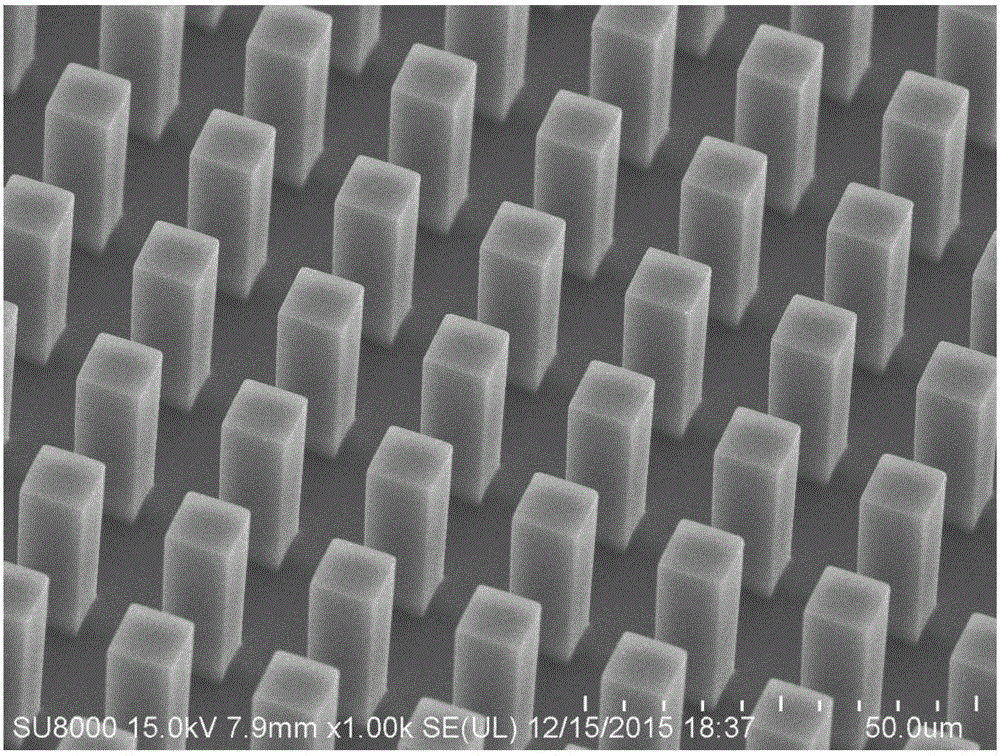

[0042] Preparation of epoxy resin prepolymer: Mix bisphenol A glycidyl ether epoxy resin E-51, n-octylamine and m-xylylenediamine in a molar ratio of 4:2:1, pour it on the PDMS intermediate template, and pump Air to remove air bubbles, curing at 60 ° C for 2 hours and then curing at 120 ° C for 12 hours. The cured samples were demolded to obtain a shape memory epoxy resin microarray surface.

[0043] Since the surface of the silicon templa...

specific Embodiment approach 2

[0050] Embodiment 2: In this embodiment, the isotropic and anisotropic switchable superhydrophobic surfaces are prepared according to the following steps:

[0051] Step 1. Use template method to prepare shape memory epoxy resin microarray

[0052] Preparation of PDMS (Dow Corning 184) intermediate template: The PDMS precursor and curing agent were mixed in a ratio of 10:1, poured on the silicon template for 65 hours and cured for 5h, and the PDMS intermediate template prepared by demolding was ready for use.

[0053] Preparation of epoxy resin prepolymer: Mix bisphenol A glycidyl ether epoxy resin E-51, n-octylamine and m-xylylenediamine in a molar ratio of 4:2:1, pour it on the PDMS intermediate template, and pump Air to remove air bubbles, curing at 60 ° C for 2 hours and then curing at 120 ° C for 12 hours. The cured samples were demolded to obtain a shape memory microarray surface.

[0054] Step 2. Temporary shape shaping of the microarray surface using the microgrooved ...

specific Embodiment approach 3

[0059] Embodiment 3: This embodiment prepares an isotropic and anisotropic switchable superhydrophobic surface according to the following steps:

[0060] Step 1. Use template method to prepare shape memory epoxy resin microarray

[0061] Preparation of PDMS (Dow Corning 184) intermediate template: The PDMS precursor and curing agent were mixed in a ratio of 10:1, poured on the silicon template for 65 hours and cured for 5h, and the PDMS intermediate template prepared by demolding was ready for use.

[0062] Preparation of epoxy resin prepolymer: Mix bisphenol A glycidyl ether epoxy resin E-51, n-octylamine and m-xylylenediamine in a molar ratio of 4:2:1, pour it on the PDMS intermediate template, and pump Air to remove air bubbles, curing at 60 ° C for 2 hours and then curing at 120 ° C for 12 hours. The cured samples were demolded to obtain a shape memory microarray surface.

[0063] Step 2. Temporary shape shaping of the microarray surface using the microgrooved structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com