Preparation method of high-purity silicon hexaboride powder

A technology of powder preparation and silicon hexaboride, applied in the direction of boron/boride, etc., can solve the problems of difficult reaction and low reaction heat effect of boron-silicon system, and achieve the effect of high chemical purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

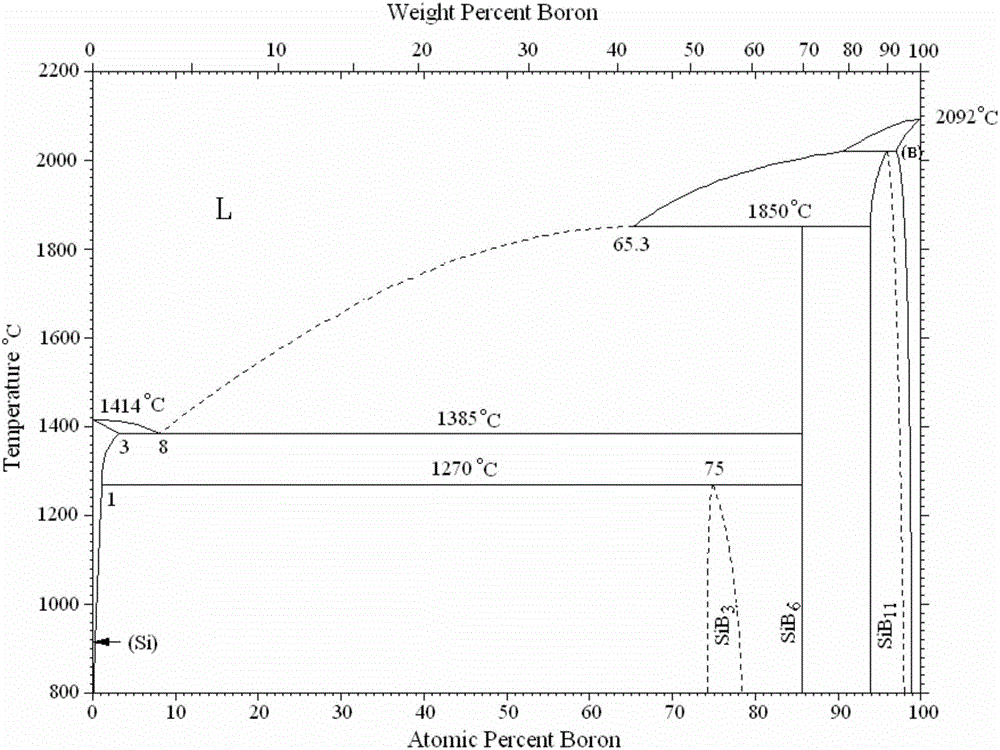

Problems solved by technology

Method used

Image

Examples

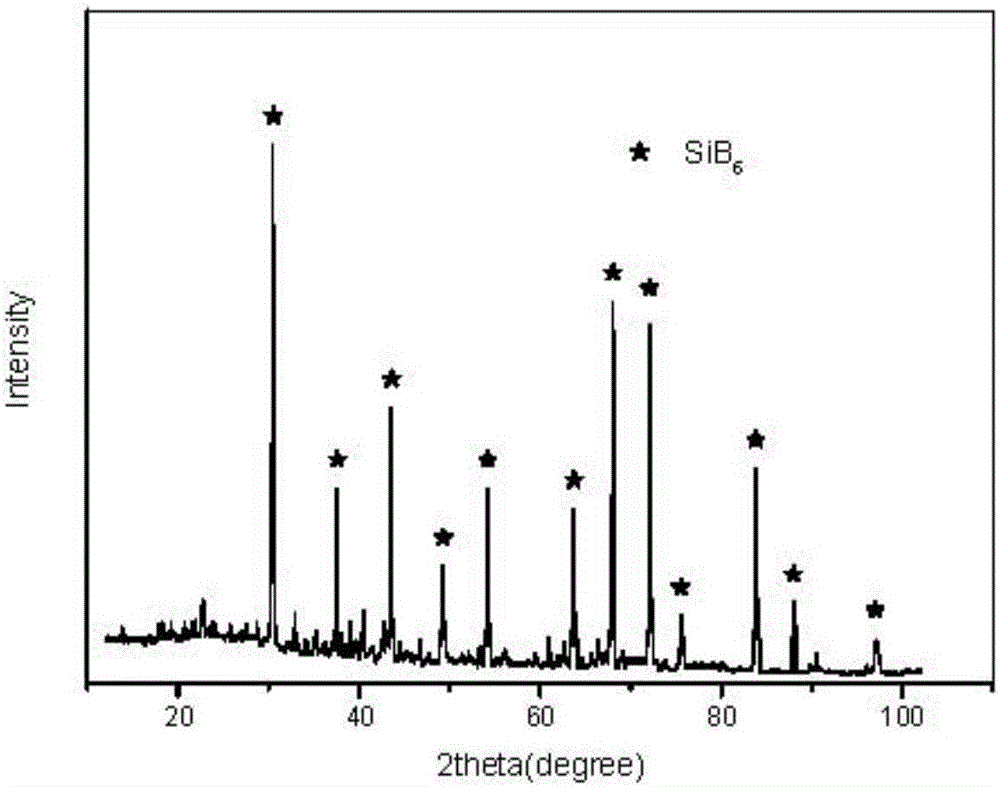

Embodiment 1

[0024] Mix 287 grams of silicon powder with an average particle size below 10 microns and 700 grams of boron powder below 20 microns with a ceramic ball mill;

[0025] After loading the crucible, put it into a gas shielded furnace, pass in argon, raise the temperature to 1400°C, and keep it warm for 60 minutes;

[0026] Drop SiCl into the furnace at the beginning of the heat preservation 4 , 5ml per minute, dripping time is 10 minutes;

[0027] After cooling, the final SiB was obtained by ball milling in a ceramic jar 6 powder product.

Embodiment 2

[0029] Mix 292 grams of silicon powder with an average particle size below 10 microns and 700 grams of boron powder below 20 microns with a ceramic ball mill;

[0030] After loading the crucible, put it into a gas protection furnace, pass in argon, raise the temperature to 1600°C, and keep it warm for 60 minutes;

[0031] Drop SiCl into the furnace at the beginning of the heat preservation 4 , 3ml per minute, dripping time is 10 minutes;

[0032] After cooling, the final SiB was obtained by ball milling in a ceramic jar 6 powder product.

Embodiment 3

[0034] Mix 290 grams of silicon powder with an average particle size below 10 microns and 700 grams of boron powder below 20 microns with a ceramic ball mill;

[0035] After loading the crucible, put it into a gas shielded furnace, pass in argon, raise the temperature to 1500°C, and keep it warm for 60 minutes;

[0036] Drop SiCl into the furnace at the beginning of the heat preservation 4 , 4ml per minute, dripping time is 10 minutes;

[0037] After cooling, the final SiB was obtained by ball milling in a ceramic jar 6 powder product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com