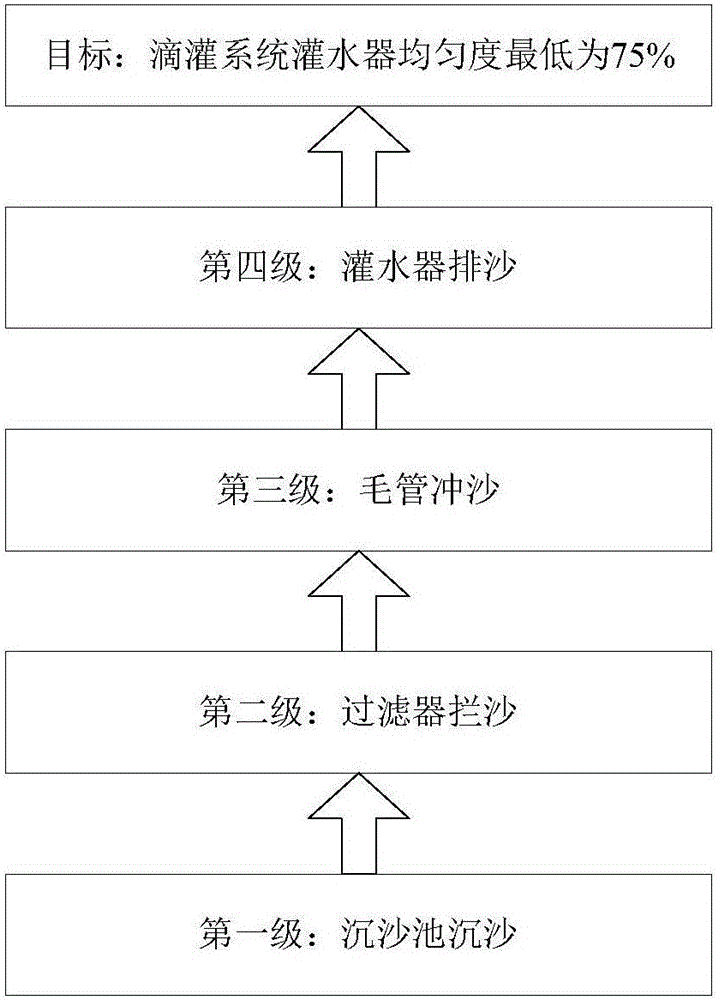

Silt step-by-step regulation and control method of drip irrigation system

A sedimentation and sedimentation technology, applied in chemical instruments and methods, botanical equipment and methods, water/sewage multi-stage treatment, etc., can solve problems such as drip irrigation with high sediment content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

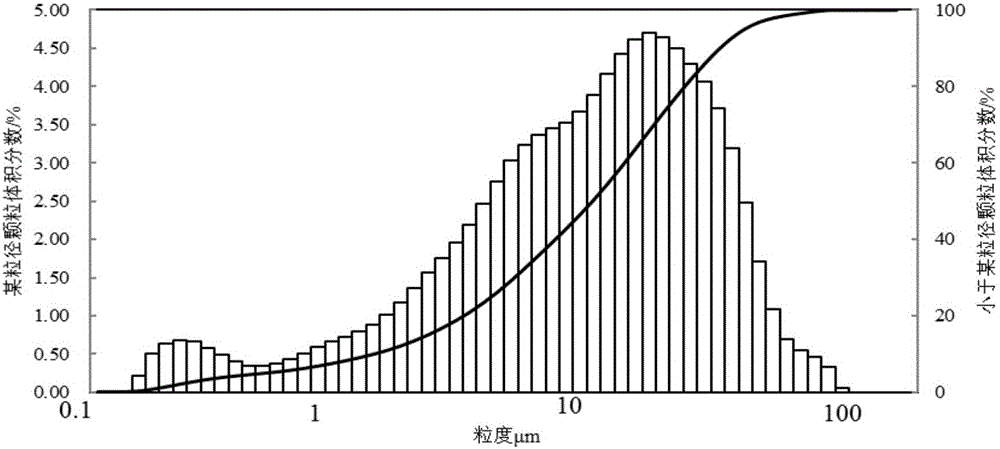

[0050] Example: The water source comes from the Wushen Main Canal in Dengkou County, Bayannaoer City, Inner Mongolia, with an annual average sediment concentration of 2.6kg / m 3 , particle size distribution such as figure 2 shown. The crops planted in this area are mainly sunflower, 3-year wolfberry and 5-year alfalfa.

[0051] According to the silt step-by-step control method of the drip irrigation system proposed by the present invention, the specific implementation process is as follows:

[0052] (1) sand sinking tank

[0053] Irrigation water enters the sedimentation tank for sedimentation. The gravity-type sedimentation and filtration composite system is used as the prototype, and inclined pipes and screens are arranged to maximize the efficiency of sedimentation. Among them, the number of screens is 150 meshes, through the rhombus, square, and honeycomb inclined tubes, the lengths are 80cm, 100cm, and 120cm, and the angles between the inclined tubes and the water flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com