Optical glass rod material drawing device

An optical glass and rod technology, applied in glass manufacturing equipment, glass production, manufacturing tools, etc., can solve the problems of inability to draw glass into sub-rods or optical fibers with circular cross-section, difficulty, easy crystallization and fringes, etc. , to achieve the effect of avoiding direct use, reducing shape requirements, and stable high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

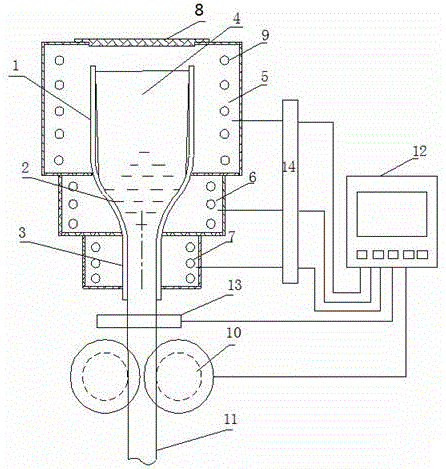

[0020] Example 1 as figure 1 , figure 2 shown. An optical glass rod drawing device of the present invention comprises a softening crucible 1, a viscosity adjusting crucible 2 and a rod forming die 3 connected from top to bottom, and a rod diameter detection device is arranged below the rod forming die 3 13. A bar pulling device 10 is installed below the bar diameter detection device 13, and also includes a temperature control device 14 and a microcomputer control device 12. Softening crucible 1, viscosity adjusting crucible 2 and bar forming mold 3 are equipped with softening crucible auxiliary furnace 5, viscosity adjusting crucible auxiliary furnace 6 and bar forming mold auxiliary furnace 7, softening crucible auxiliary furnace 5, viscosity adjusting crucible auxiliary furnace The furnace 6 and the auxiliary furnace 7 of the bar forming mold are respectively equipped with 9 groups of independent heating rods, and the 9 groups of three independent heating rods are respect...

Embodiment 2

[0027] Example 2 as image 3 shown. In Example 2, the cavity cross section of the softening crucible 1 is circular, and the cavity cross section of the bar forming die is oval.

Embodiment 3

[0028] Example 3 as Figure 4 shown. In Example 3, the cavity cross section of the softening crucible 1 is circular, and the cavity cross section of the bar forming mold is rectangular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com