Bionic microcapsule self-lubrication composite material and preparation method thereof

A technology of self-lubricating materials and composite materials, applied in the field of bionic microcapsule self-lubricating composite materials and their preparation, to achieve the effects of improving application, reducing friction and wear, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples further illustrate the technical solutions of the present invention, but are not intended to limit the protection scope of the present invention.

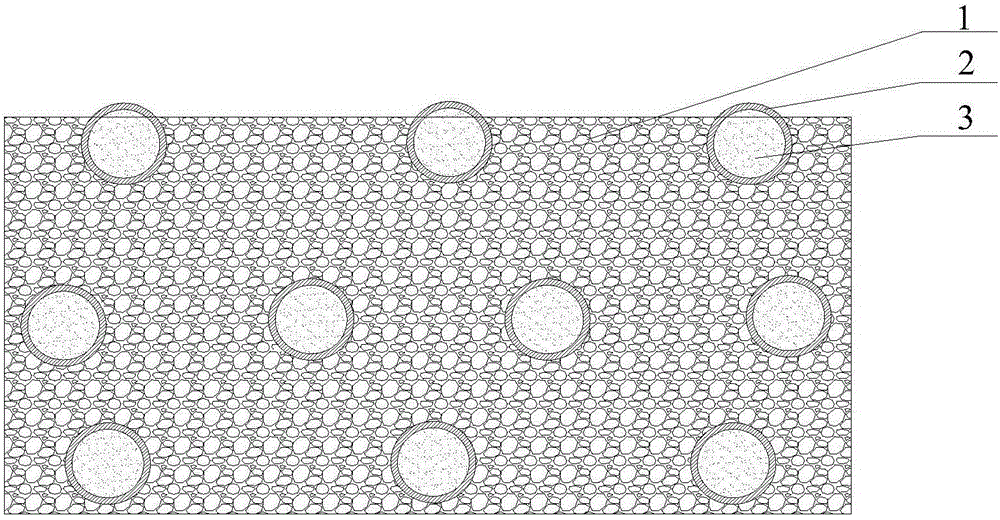

[0029] Biomimetic microcapsule self-lubricating composite materials, such as figure 1 As shown, it includes a matrix material 1 and a microcapsule structure with lubricating properties, and the microcapsule structure is uniformly mixed in the matrix material; wherein, the matrix material is ultra-high molecular weight polyethylene; the microcapsule structure is composed of a polymer film 2 and a substrate The self-lubricating material 3 enveloped in the polymer film is composed of a microcapsule structure with a diameter of 1-300 μm and a thickness of the polymer film of 0.3-50 μm.

[0030] The preparation steps of the bionic microcapsule self-lubricating composite material of the present invention are as follows:

[0031] 1) The preparation of the microcapsule structure, using guaiac resin self-lubri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com