System and method for sweeping accumulated dust through steam produced during garbage pyrolysis after waste heat is recovered

A water vapor and garbage technology, which is applied to the system field of purging radiant tubes to accumulate dust, can solve the problems of dust on the surface of the radiant tubes, waste, and affect the heating capacity of the radiant tubes, and achieve the effect of restoring the heating capacity and avoiding the loss of heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

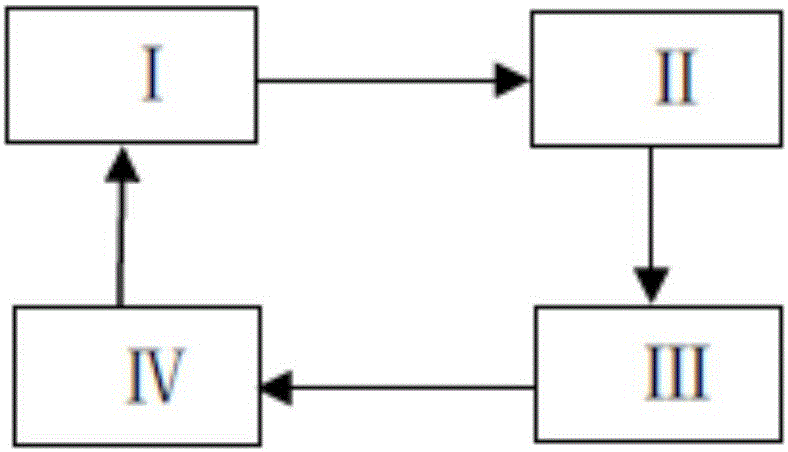

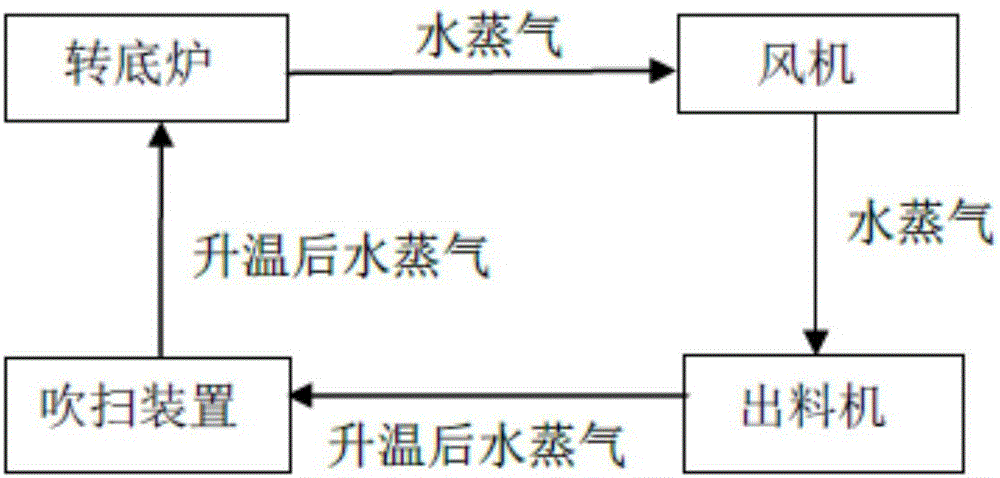

[0061] The garbage raw materials are transported to the rotary hearth furnace for drying and pyrolysis, and the pressure in the drying zone is maintained to be 5Pa higher than the pressure in the feeding zone and the pyrolysis zone respectively, and the water vapor temperature at the gas outlet of the drying zone is 120-180°C. The water vapor is transported to the indirect cooling screw discharger, and the temperature is raised to 450°C. The heated water vapor is transported to the purging device, and then the heated water vapor is sprayed into the surface of the radiant tube in the rotary hearth furnace by the purging device to remove the ash accumulated on it.

Embodiment 2

[0063] The steps in this example are the same as those in Example 1. The pressure in the drying zone is maintained to be 8Pa higher than the pressure in the feed zone and the pyrolysis zone respectively. The water vapor temperature at the gas outlet of the drying zone is 180-230°C, and the temperature of the water vapor after heating is 500°C. , other conditions are the same as in Example 1.

Embodiment 3

[0065] The steps in this example are the same as those in Example 1. The pressure in the drying zone is maintained to be 10 Pa higher than the pressure in the feed zone and the pyrolysis zone. The water vapor temperature at the gas outlet of the drying zone is 230-400°C, and the temperature of the water vapor after heating is 500°C. , other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com