A complete set of equipment and method for refining precious metals from circuit board waste

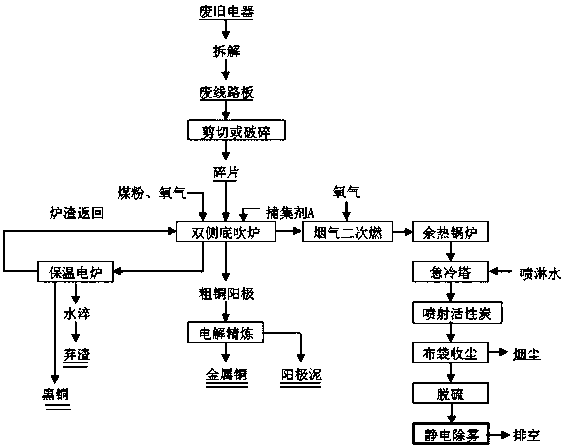

A circuit board and precious metal technology, which is applied in the field of complete sets of equipment for refining precious metals, can solve the problems of secondary environmental pollution caused by dioxins, and achieve the effects of saving energy consumption, no secondary pollution, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

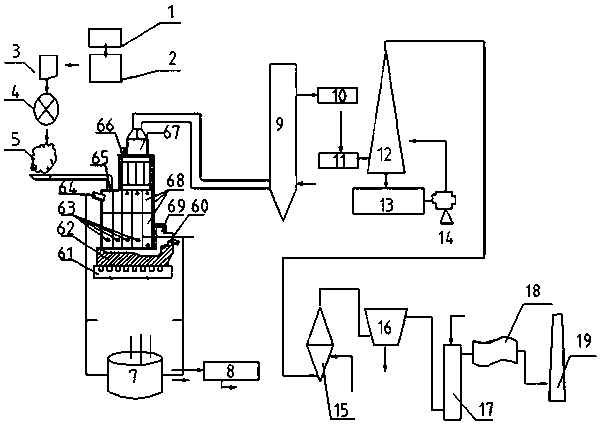

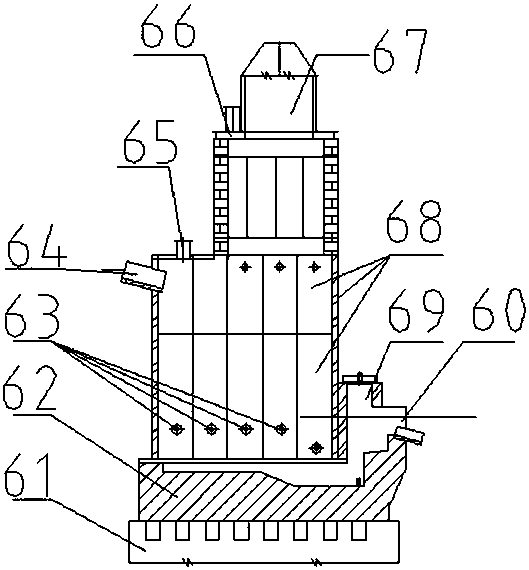

[0065] Such as figure 1 , 2 As shown, the complete set of equipment:

[0066] The complete set of equipment includes shearing machine 3, pulverizer 4, fragment material 5, double-sided bottom blowing furnace (hereinafter referred to as bottom blowing furnace), heat preservation electric furnace 7, water quenching pool 8, flue gas secondary combustion furnace 9, primary preheating Boiler 10, secondary preheating boiler 11, spray quenching tower 12, pool 13, water pump 14, absorption tower 15, pulse bag filter 16, wet desulfurization device 17, electrostatic dust and mist removal device 18, chimney 19.

[0067] The bottom blowing furnace includes slag outlet 60, furnace base 61, hearth 62, wind eye 63, slag inlet 64, solid feeding inlet 65, top water jacket 66, flue 67, copper water jacket 68, siphon outlet 69 . The hearth 62 is set on the furnace base 61, the hearth is set on the hearth 62, the hearth is provided with a copper water jacket 68, the top of the hearth is a furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com