A straight-through double-channel gas injection valve

A gas injection valve and dual-channel technology, which is applied to combustion engines, internal combustion piston engines, charging systems, etc., can solve the problems of large driving current and small driving current, and achieve small opening current, weight reduction, and lower opening force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

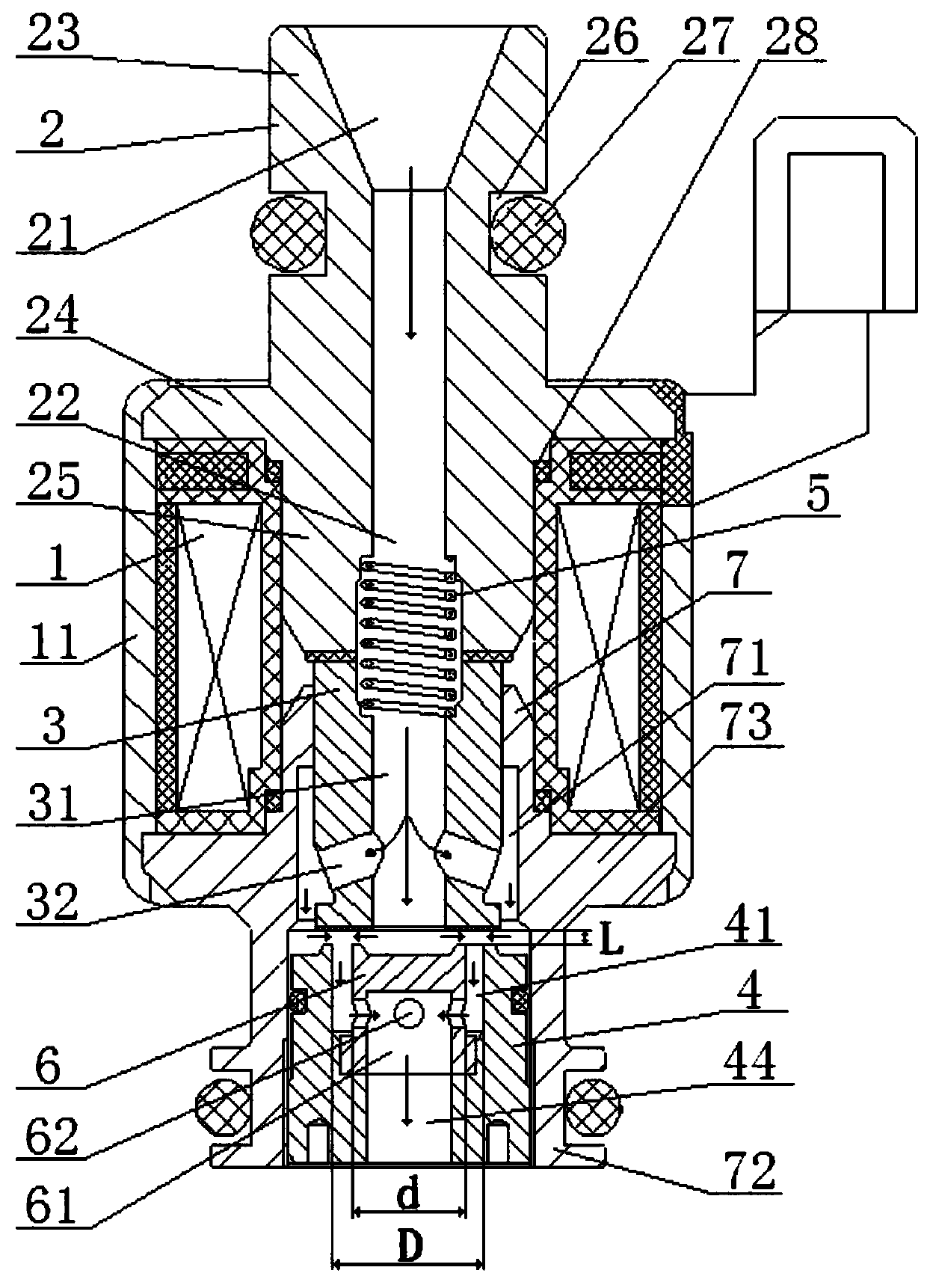

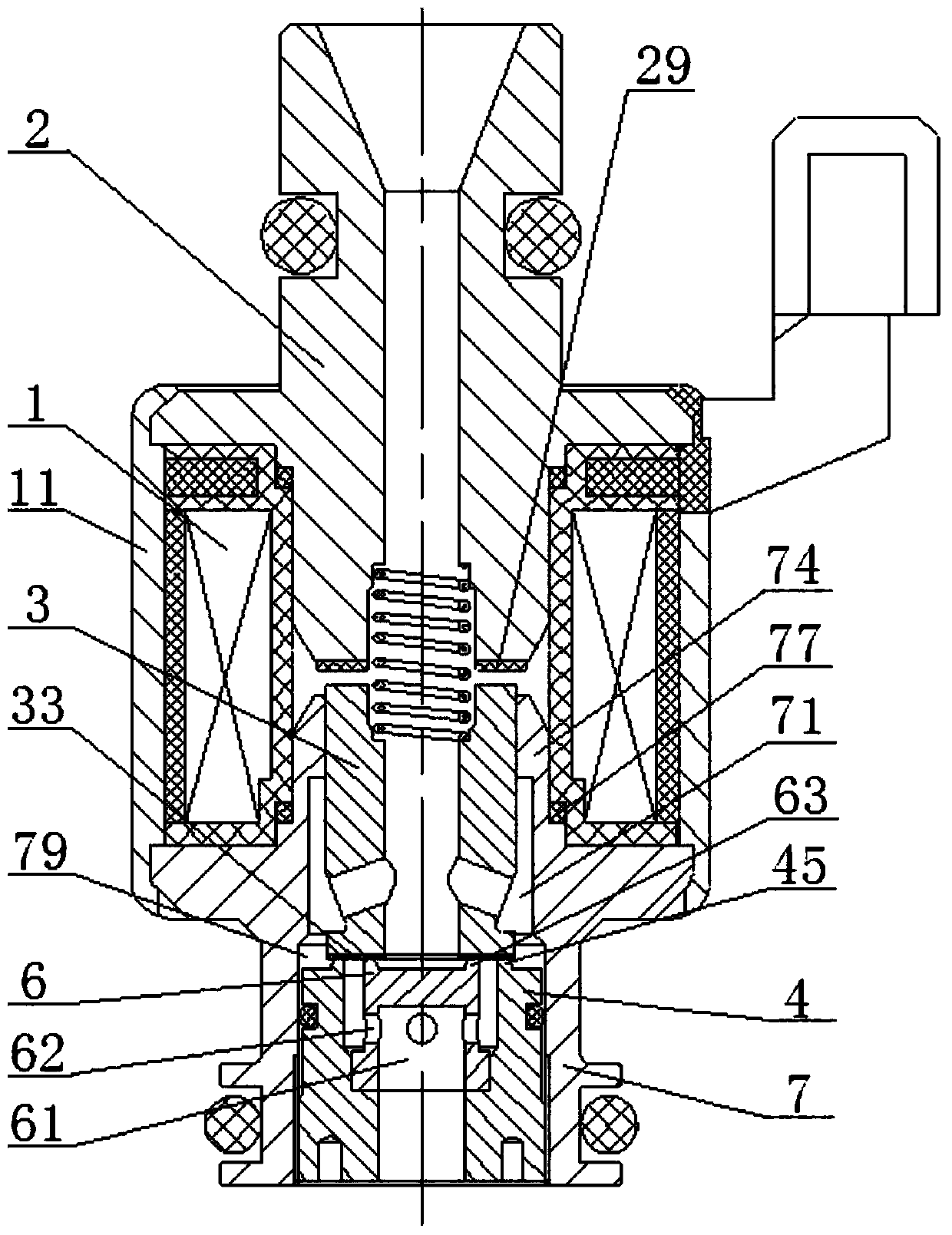

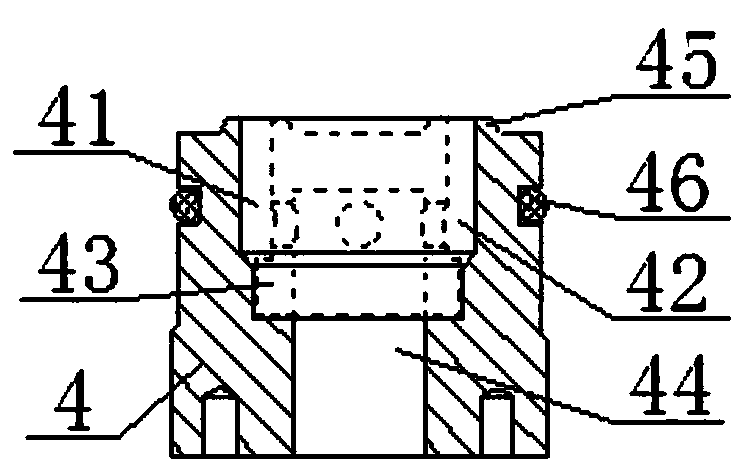

[0054] see Figure 1 to Figure 4 , a straight-through dual-channel gas injection valve, comprising a coaxially arranged electromagnetic coil 1, a fixed iron core 2, a moving iron core 3 and a nozzle 7, the upper and lower ends of the electromagnetic coil 1 are respectively connected with the fixed iron core 2 , The nozzle 7 is sealed and matched, the top of the nozzle 7 is slidingly matched with the outer side wall of the moving iron core 3, and a return spring 5 is arranged between the moving iron core 3 and the fixed iron core 2; the middle of the nozzle 7 is provided with In the air inlet cavity 71, the lower end of the nozzle 7 is coaxially provided with a valve seat 4, the outer side wall of the valve seat 4 is in sealing fit with the inner side wall of the nozzle 7, and the middle part of the valve seat 4 is coaxially provided with an auxiliary valve seat 6 , the tops of the valve seat 4 and the auxiliary valve seat 6 are press-fitted with the bottom of the moving iron c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com