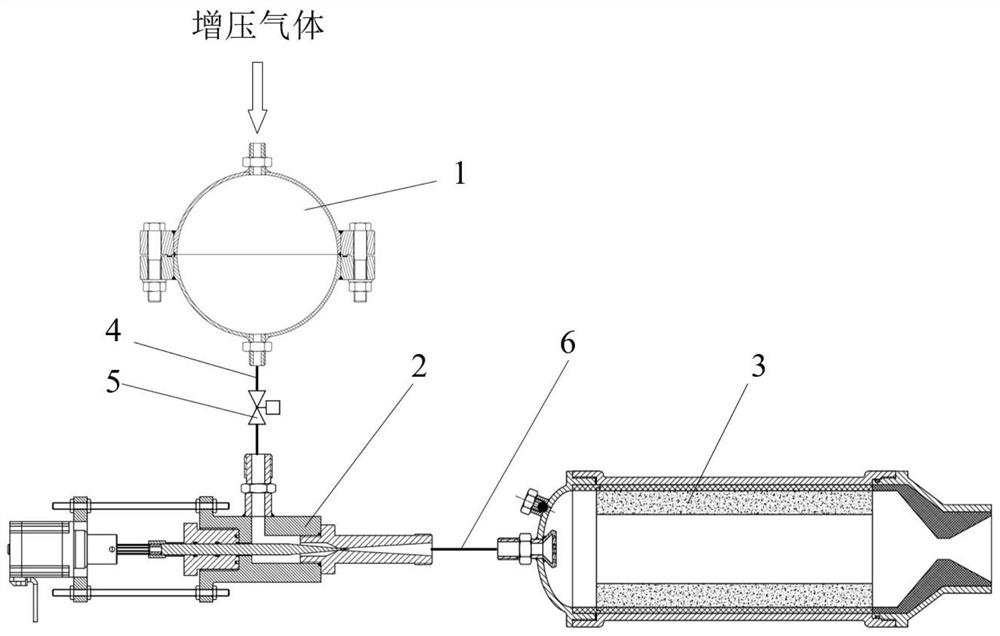

Variable-flow solid-liquid mixing engine

A solid-liquid mixing and engine technology, which is applied in the direction of machines/engines, rocket engine devices, mechanical equipment, etc., can solve the problems of easy wear and low service life of needle cones, and achieve stable transportation, excellent pressure resistance, and reduced quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

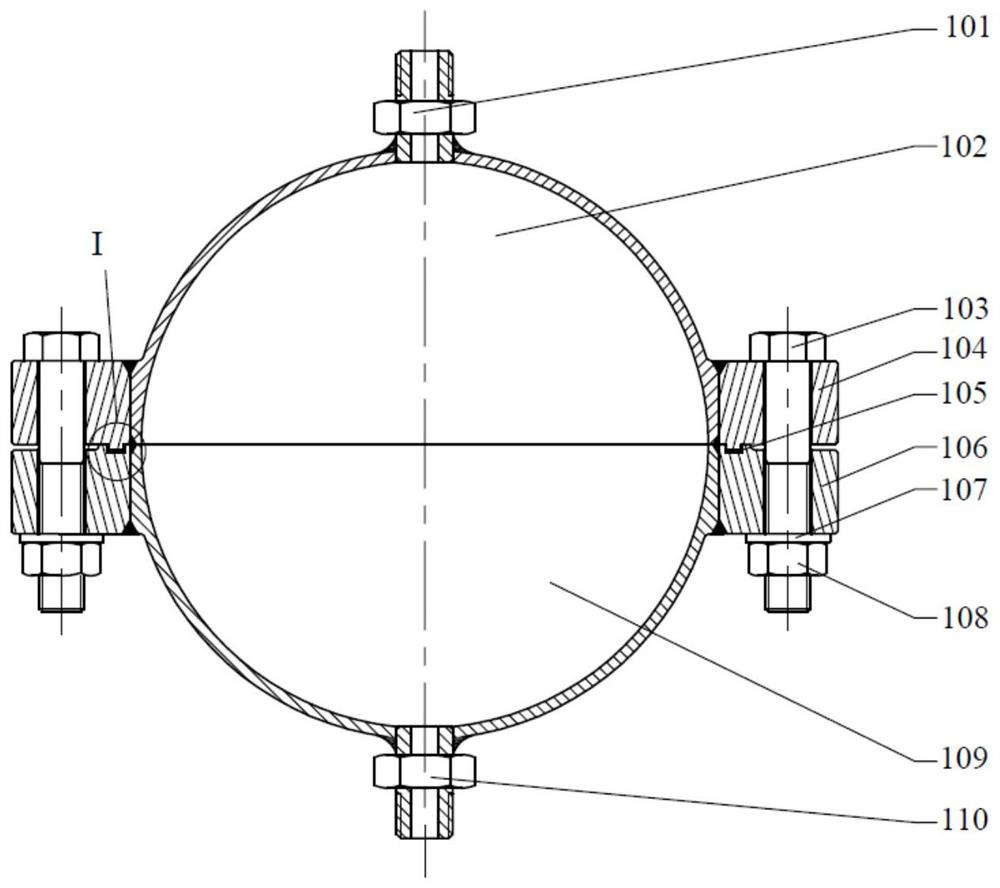

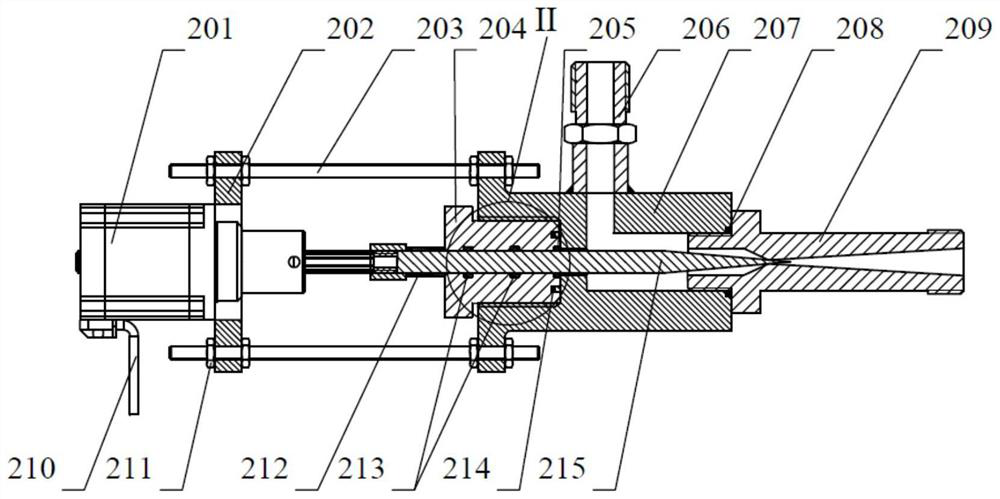

Method used

Image

Examples

example 1

[0057] The fuel of the solid-liquid hybrid engine is paraffin wax, the drug type of the fuel is tube type, and it is loaded into the thrust chamber in the form of free filling. The oxidant is nitrous oxide, which is filled into the oxidant storage tank in advance, and the pressurized gas is nitrogen. The flow rate is adjusted by the movement of the cavitation venturi needle cone. The flow rate of the oxidant changes from small to large. It is divided into 3 stages. The flow rate of each stage is 30g / s, 50g / s and 80g / s respectively. The initial position of the needle cone is zero, and the positions corresponding to the needle cone are 0mm, 1mm and 2mm respectively. 17s.

[0058]After the assembly of the various components of the solid-liquid hybrid engine is completed, the control valve on the first pipeline is opened, and under the extrusion of the pressurized gas, the oxidant flows through the adjustable cavitation venturi tube to be restricted, and then reaches the thrust th...

example 2

[0060] The fuel of the solid-liquid hybrid engine is HTPB (hydroxyl-terminated polybutadiene). The fuel drug type is star-shaped, which is loaded into the thrust chamber in the form of free filling. The gas is nitrogen. The flow rate is adjusted by the movement of the cavitation venturi needle cone. The flow rate of the oxidant changes from large to small and then to large. It is divided into 3 stages, and the flow of each stage is 50g / s, 30g / s and 80g / s respectively. , it is stipulated that the initial position of the needle cone is the zero position, the corresponding positions of the needle cone are 0mm, -1mm and 1mm respectively, the supply time is 3s, the switching time of the working condition is 1s, and the flow rate changes from large to small. The speed of the needle cone is 1mm / s, the movement speed of the needle cone is 2mm / s when the flow rate changes from small to large, and it takes 11s to change the flow rate.

[0061] After the assembly of the various compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com