Two-dimensional taper roller piston pump

A technology of tapered roller and piston pump, applied in the field of hydraulic pump and hydraulic motor, can solve the problems of rapid cylinder temperature rise, large moment of inertia, displacement limitation, etc., to reduce contact stress, simplify the overall structure, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

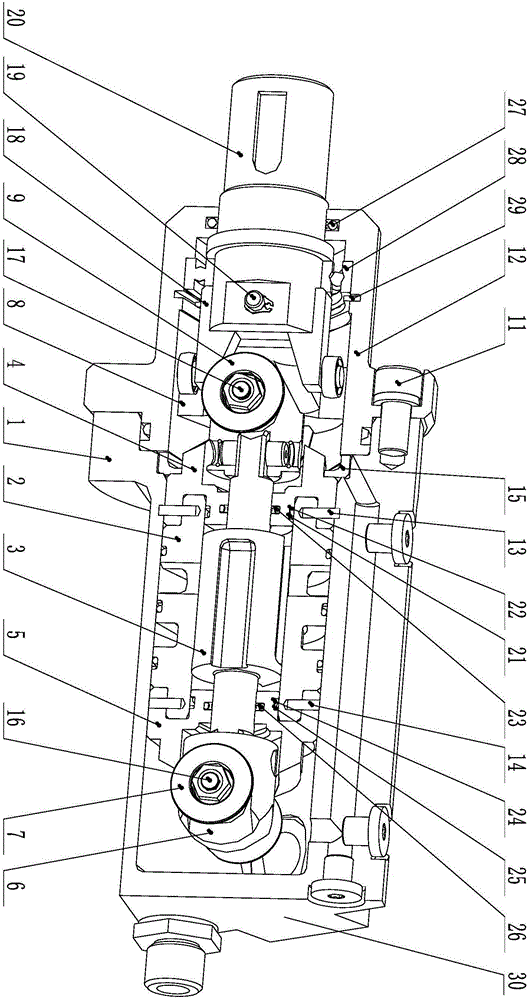

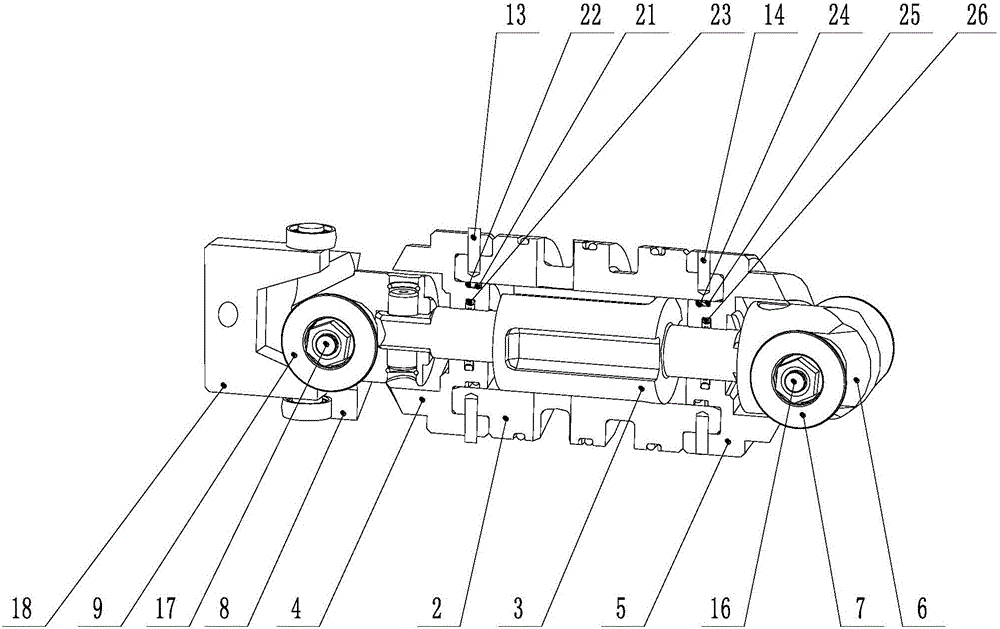

[0065] Referring to the accompanying drawings, the two-dimensional tapered roller piston pump includes a pump body 1 with a liquid suction hole and a liquid discharge hole. The pump body 1 is provided with a pump unit, and the pump unit is connected to the motor.

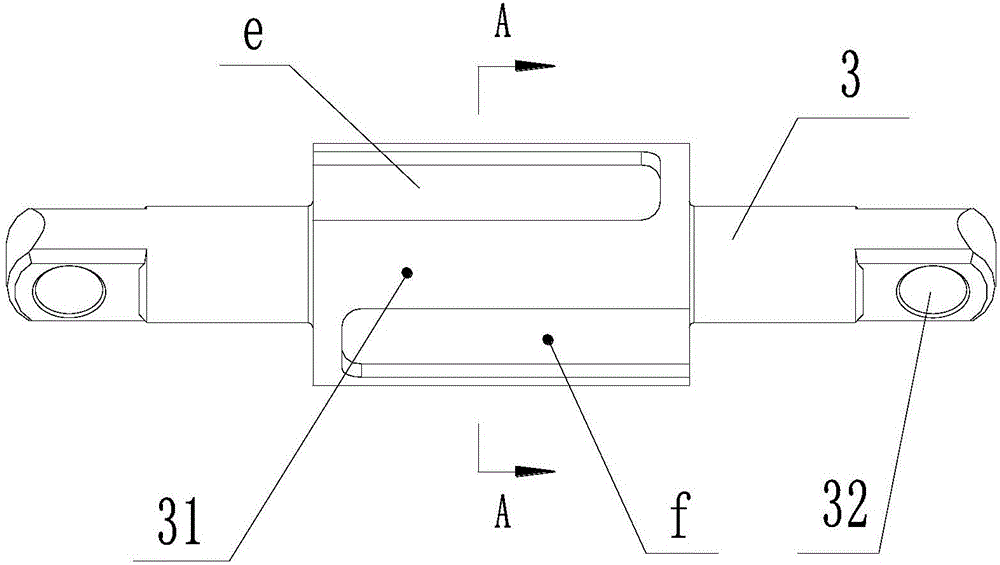

[0066] The pump unit includes a cylinder 2 fixed in the pump body 1, a piston 3 is arranged in the cylinder 2, the central axis of the cylinder 2 coincides with the central axis of the piston 3, and both ends of the piston 3 are equipped with a drive piston 3 axially The trigger device that moves to cause the volume of the working chamber to change, and the trigger devices at both ends of the piston 3 drive the piston 3 to move in the opposite direction;

[0067] The working chamber includes a left chamber and a right chamber respectively located at both ends of the cylinder body. A shoulder 31 is provided in the middle of the piston 3. The left end surface of the shoulder 31 and the guide rail 4 on the left side enc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com