Flexible bolt with hexagonal-groove threaded end socket

A hexagonal and threaded end technology, applied in the field of flexible bolts, can solve the problems of reduced production efficiency, thick thickness, large size, etc., and achieve the effects of improving production efficiency and work efficiency, expanding contact area, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

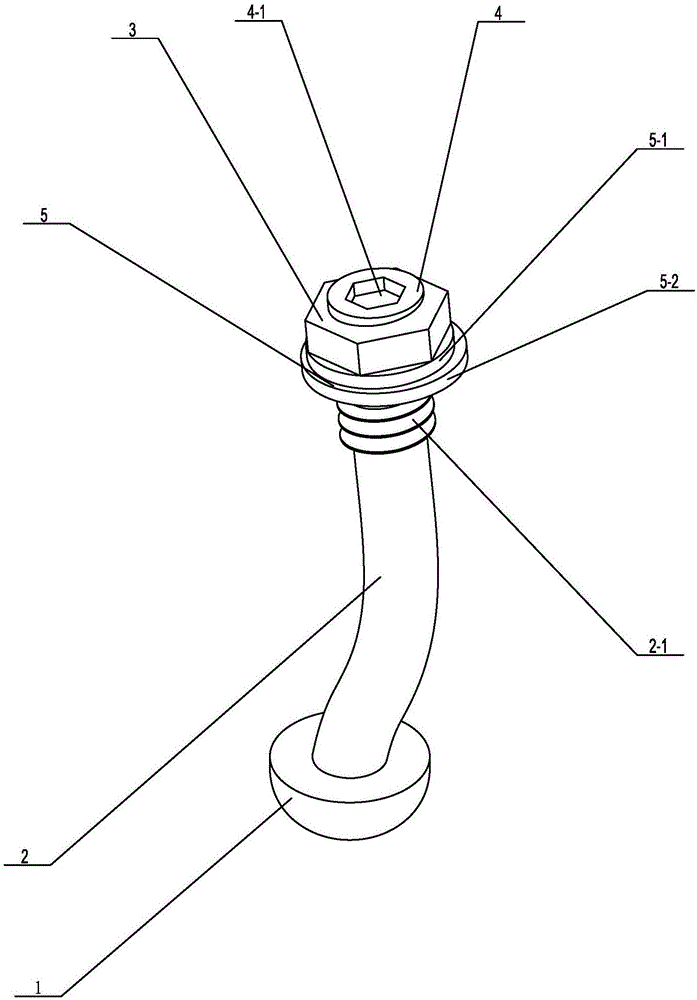

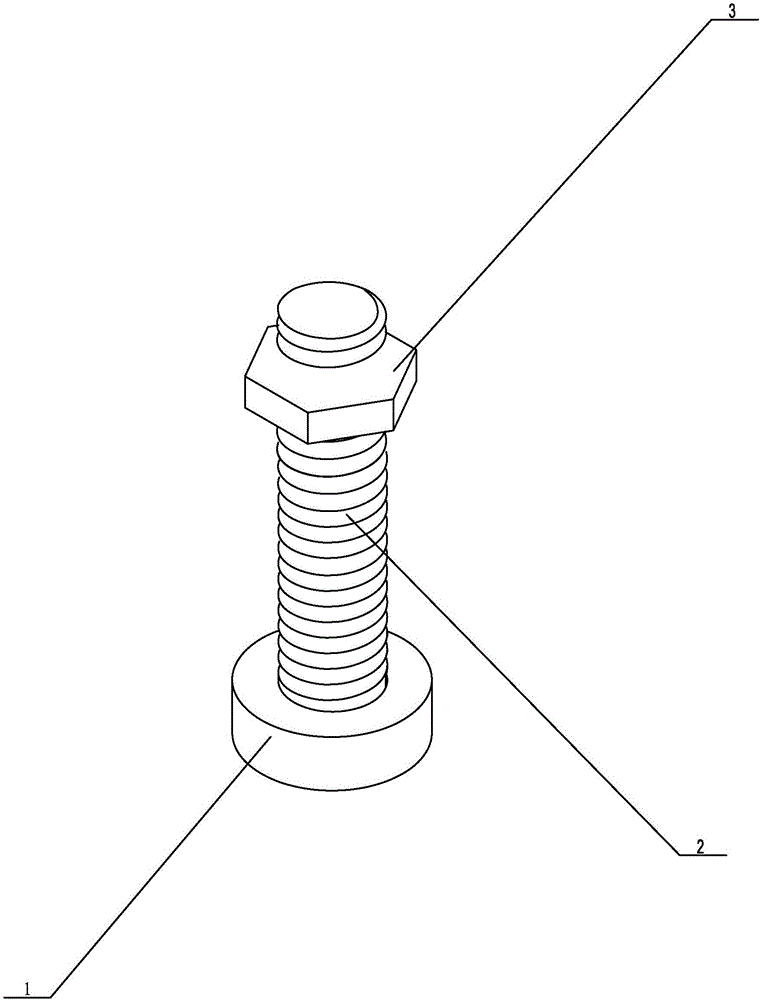

[0015] like figure 1 A specific embodiment of the present invention is proposed as shown, a flexible bolt with a hexagonal groove threaded end, comprising a bolt head 1, a screw rod 2 connected to the bolt head 1 and having a cylindrical structure, and a screw rod 2 Cooperate with the connected nut 3, the bolt head 1 can be set to be hexagonal, hemispherical, or cylindrical. In this embodiment, it is selected to be hemispherical, so that the bolt head 1 can be easily screwed into the connected parts. The length of the screw rod 2 It can be reasonably set according to different needs. The screw rod 2 is a steel bar made of bendable spring steel material, and its end is set as a threaded end 2-1. The screw rod 2 can be bent at a large angle, but There is almost no change in stiffness to ensure the stability between the connecting parts. The top of the threaded end 2-1 is provided with a threaded end 4 that is connected to it and is used to fix the screw 2 when the bolt is tight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com