Heat source tower heat pump using passive external auxiliary heating defrosting prevention device

A technology of heat source tower heat pump and heat source tower, which is applied in the direction of household heating, application, heating methods, etc., can solve the problems of large initial investment, reducing the heat supply of heat pumps, heat defrosting, etc., and achieves flexible installation methods and a wide range of applications , the effect of convenient heat source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

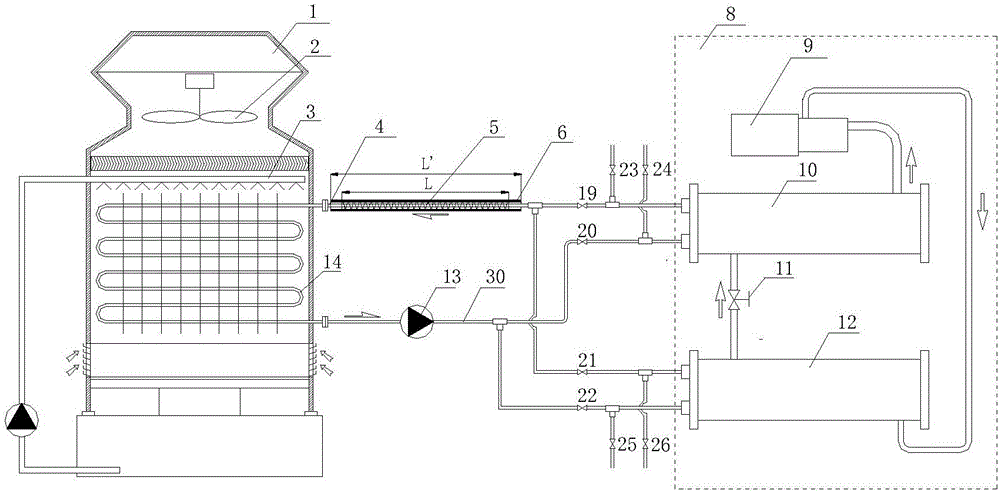

[0039] see figure 1 , the heat source tower 1 is connected to the heat pump unit 8 through the brine transmission pipeline 4 and the brine circulation pump 13, the electric heating device 5 is installed on the brine transmission pipeline 4, and the exposed part of the electric heating device and the transmission pipe is coated There is an insulation layer, and the length L of the electric heating device is determined by the heat required for the maximum anti-defrosting. The length L' of the insulation layer starts from the connection between the brine transmission pipeline 4 and the heat source tower heat exchanger 14, and ends at the electric heating device 5 and then Past the length of 0.5-1m.

[0040] Refrigerant cycle in heat pump figure 1 As indicated by the arrow in the dashed box of the heat pump unit 8 , the function of heating or cooling the user side is realized by adjusting the valves 19 , 20 , 21 , 22 , 23 , 24 , 25 , and 26 . When heating in winter, open the val...

example 2

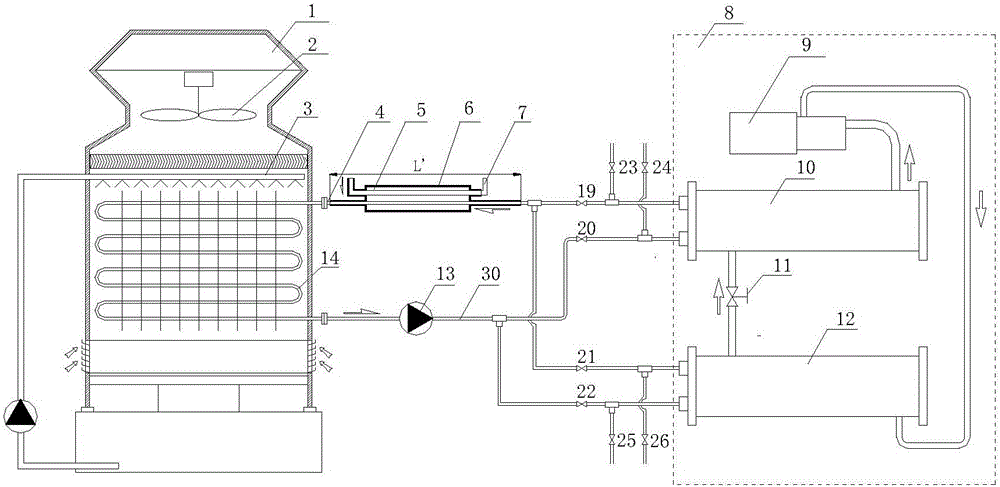

[0044] see figure 2 , figure 2 The basic principle is the same as figure 1 , the difference is that the electric heating device is replaced by hot water or hot oil or hot gas heat exchanger 5, and at the same time, the heat exchanger and the exposed refrigerant transmission pipeline are covered with an insulation layer, and the area of the heat exchanger is changed from the largest anti-defrost The required heat and the average temperature of the heat medium are determined, and the length L' of the insulation layer starts from the connection between the brine transmission pipeline 4 and the heat source tower heat exchanger 14, and ends at the heat exchanger 5 and then passes the length of 0.5-1m. When anti-defrosting is required, the heat medium is supplied into the heat exchanger 5 to heat the brine, and the brine enters the heat source tower heat exchanger 14 to defrost. When anti-defrosting ends, stop supplying heat medium, here heat quality refers to heat fluid such ...

example 3

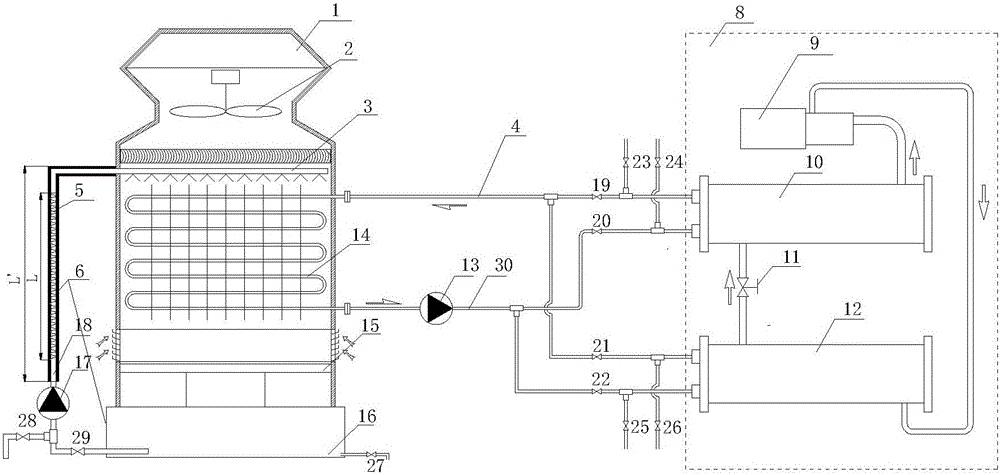

[0046] see image 3 , the heating device is installed on the outer wall of the spray transmission pipe of the heat source tower, image 3 and figure 1 In comparison, only the heating device 5 is changed from the brine transmission pipeline 4 to the spray liquid transmission pipe 18, the heating device 5 is an electric heating device or a hot water, hot oil or hot gas heat exchanger, the length L of the heating device or the heat exchange area Determined by the maximum heat required for anti-defrosting, the outer surface of the heating device 5, the outer surface of the exposed spray liquid transmission pipe 18 and the outer wall of the solution pool 16 are coated with an insulating layer, and the length L' of the insulating layer is from the solution pool 16 to the spray From the junction of the shower liquid delivery pipe 18 to the junction of the shower liquid delivery pipe 18 and the shower 3 , excluding the pipeline length of the pump 17 . The anti-defrost solution is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com