Float type water discharge device for cooling tower

A technology of water outlet and cooling tower, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of instability, can no longer eliminate water surface vortex, equipment damage, etc. and the effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

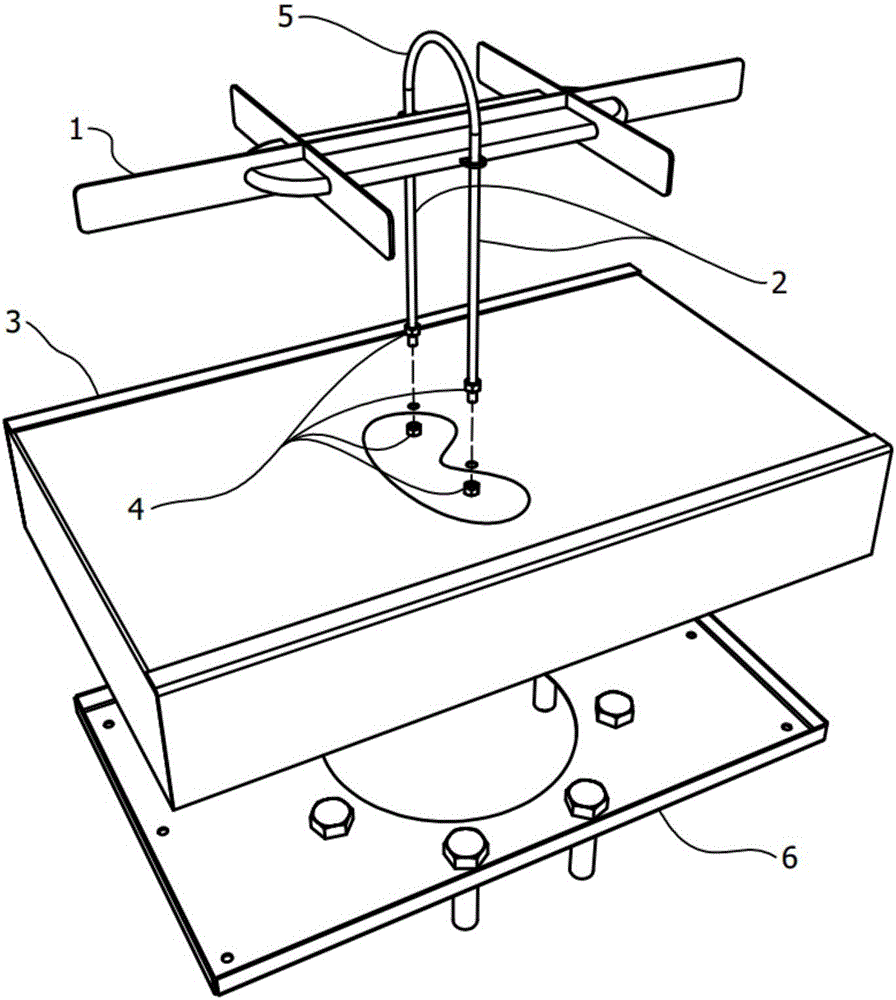

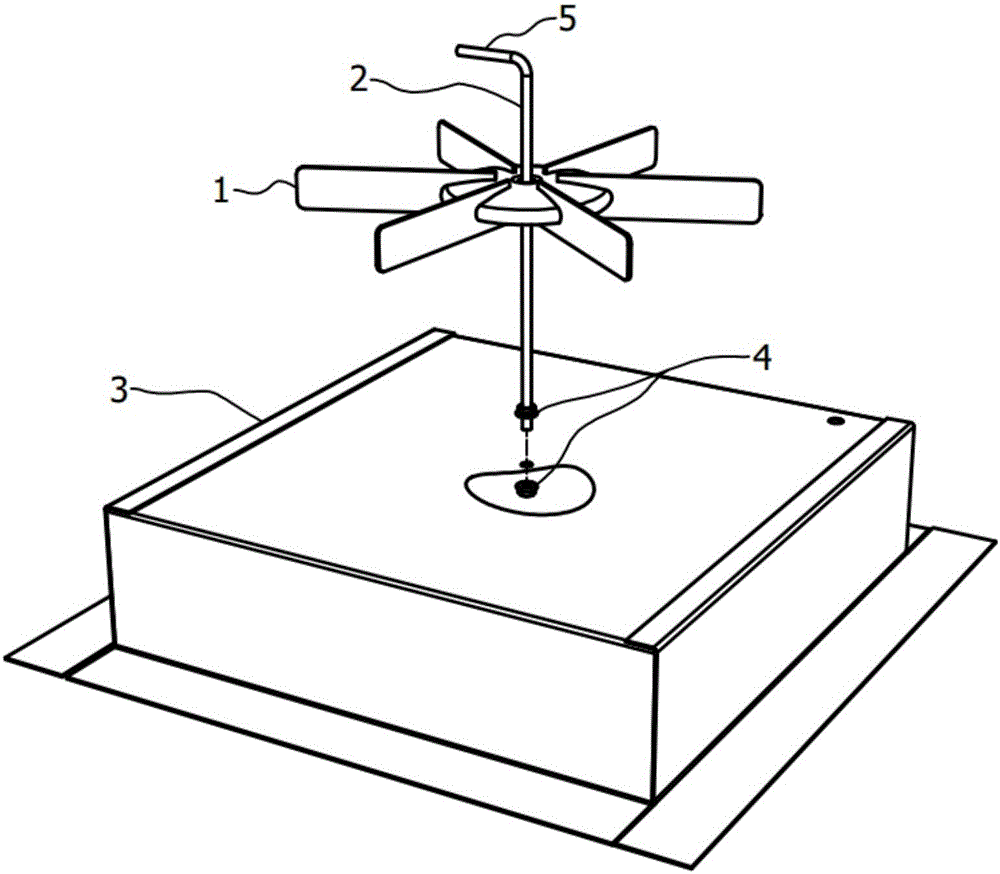

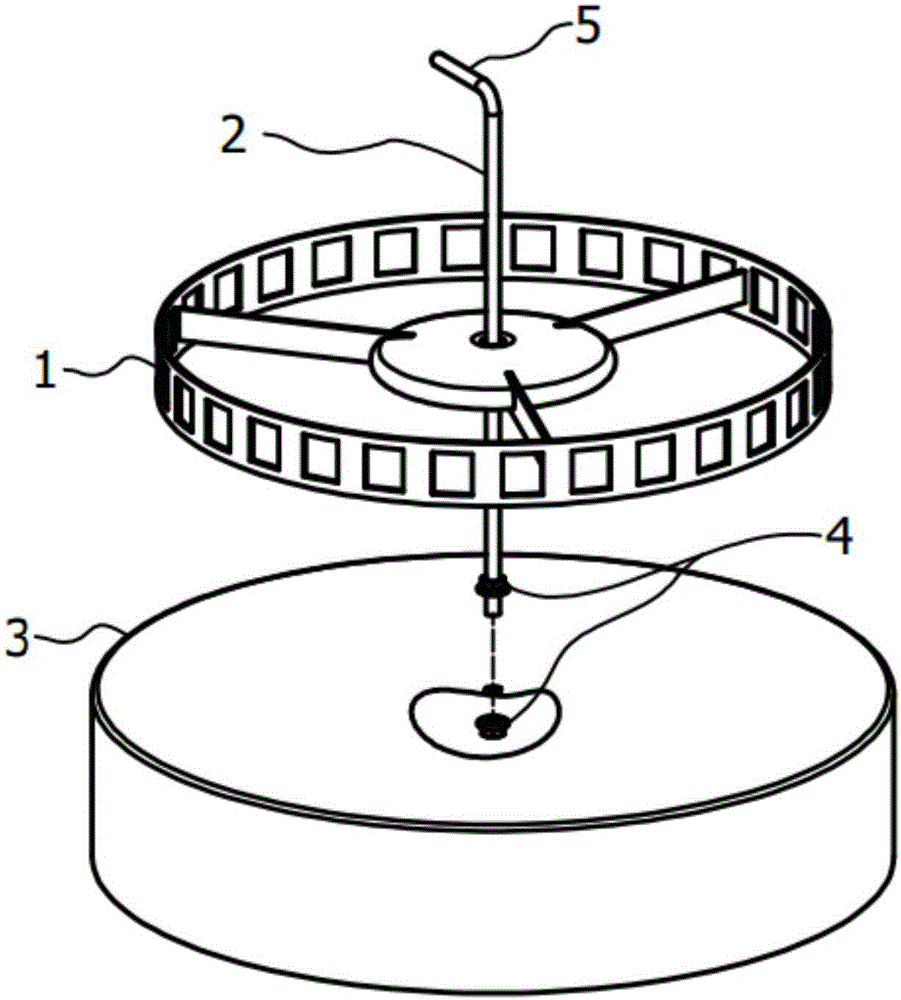

[0032] In order to achieve the purpose of the present invention, as figure 1 As shown, in one of the embodiments of the present invention, a kind of float type cooling tower water outlet device is provided, comprising:

[0033] Filter box 3, the filter box 3 is a cuboid prism structure, and each surface of the filter box 3 is provided with several filter holes;

[0034] The float guide mechanism includes a guide rail 2 and a float mechanism 1, the guide rail 2 is vertically arranged in the middle of the upper surface of the screen box 3, the top of the guide rail 2 is provided with a limiter 5, and the float mechanism 1 is moved and arranged on the guide rail 2;

[0035] A seal (not shown in the figure) is arranged around the lower surface of the screen box 3 .

[0036] Compared with the prior art, this embodiment has the filter box 3 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com