Method for controlling air gap thickness in Otto structure by using dielectric film

A dielectric film, air gap technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve problems such as difficult control, influence, and insufficient accuracy of mechanical control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to clarify the technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited by this.

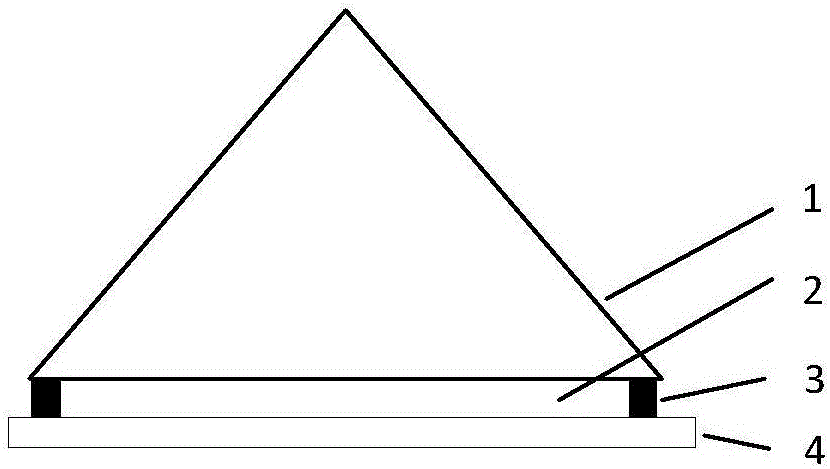

[0036] Please refer to figure 1 , figure 1 It is a schematic diagram of the Otto structure formed after implementing the invention on the bottom surface of the prism. The structure is composed of four parts: an isosceles rectangular prism 1, a fixed air gap thickness 2, a rectangular parallelepiped dielectric film 3, and a metal film 4 to be tested.

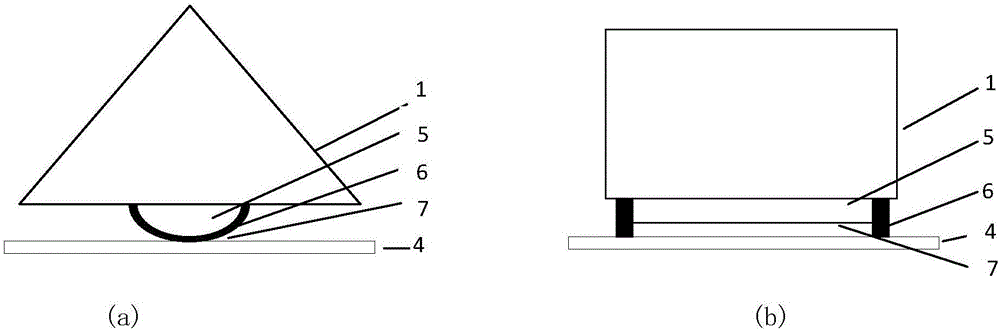

[0037] Please refer to figure 2 , figure 2 It is a schematic diagram of the Otto structure formed after implementing the invention at both ends of the cylindrical mirror surface, wherein (a) is a front view of the structure, and (b) is a side view of the structure, and the structure is composed of five parts: prism 1, Cylindrical mirror 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com