Bragg fiber grating temperature sensor, temperature monitoring system and monitoring method of temperature monitoring system

A technology of temperature sensor and fiber grating, which is applied in the field of temperature monitoring of thyristor of high-voltage power transmission converter valve, can solve the problems of complex temperature field distribution in the shell and difficult to derive accurately, and achieves convenient and fast installation, small error and good linearity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

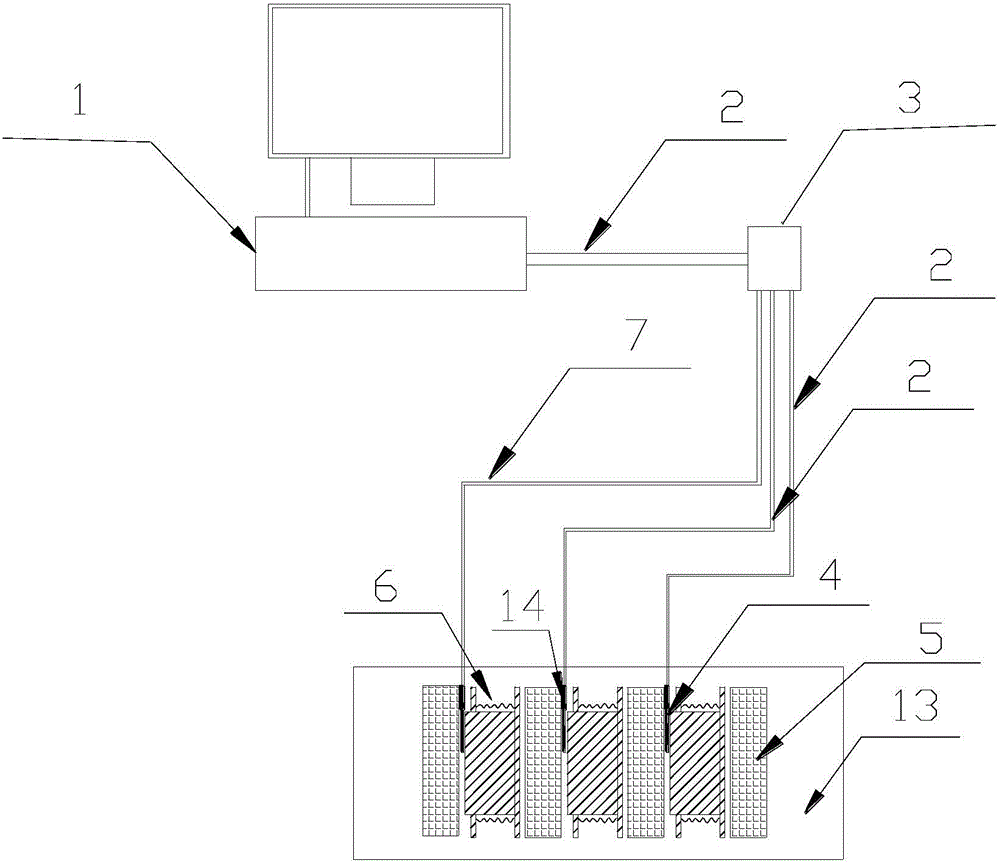

[0045] 1. Bragg fiber grating temperature sensor 4 design

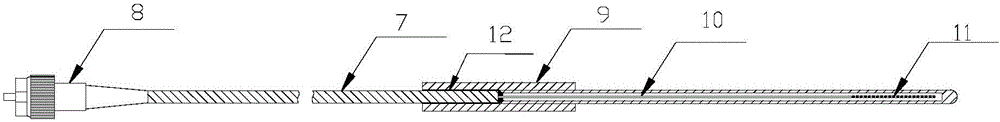

[0046] figure 2 Design drawing for Bragg FBG temperature sensor 4. Such as figure 2 As shown, a Bragg fiber Bragg grating temperature sensor 4 includes: a high-voltage insulating sheath tube 7, an optical fiber connector 8, a packaged metal casing 9, a photosensitive optical fiber 10, and a Bragg fiber Bragg grating 11;

[0047] The photosensitive optical fiber 10 is divided into front and rear two parts, the high voltage resistant insulating sheath tube 7 is arranged outside the front part of the photosensitive optical fiber 10, and the end of this part of the photosensitive optical fiber 10 is connected to the optical fiber connector 8, and the Bragg optical fiber The grating 11 is arranged at the end of the photosensitive optical fiber 10 at the rear, and the encapsulating metal casing 9 is arranged outside the end of the high-voltage insulating sheath tube 7 facing the Bragg fiber grating 11 .

[0048] Bare f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com