Cutting finishing method based on STL defect model

A model and three-dimensional model technology, applied in the field of cutting and trimming based on STL defect models, can solve problems such as broken contours of bone defect STL models, inability to print out physical models, irregular triangular meshes, etc., achieving easy success, simple operation, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

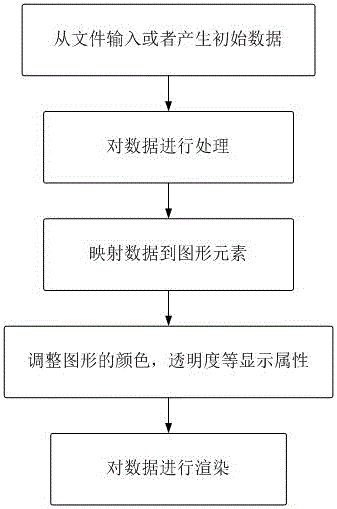

[0035] The cutting and trimming method based on the STL defect model of the present invention comprises the following steps:

[0036] Step 1, read in the CT data of the defect bone model

[0037] CT data is stored in DICOM format, and DICOM files are specifically composed of file headers and data sets. Using MITK (Medical Imaging ToolKit, medical imaging development kit) to realize the reading and writing of CT data. In MITK, the read and write operations of image files are packaged modularly, and a simple interface is provided for users, which is convenient for users to use. The classes customized in MITK to complete the reading and writing functions of DICOM files are mitkDICOMReader and mitkDICOMWriter, which mainly extract the data structure and algorithm for realizing the reading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com