Pixel structure, manufacturing method and display panel

A pixel structure and pixel technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of shortening the service life of display devices and increasing the power consumption of display panels, so as to improve light extraction efficiency, reduce power consumption, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

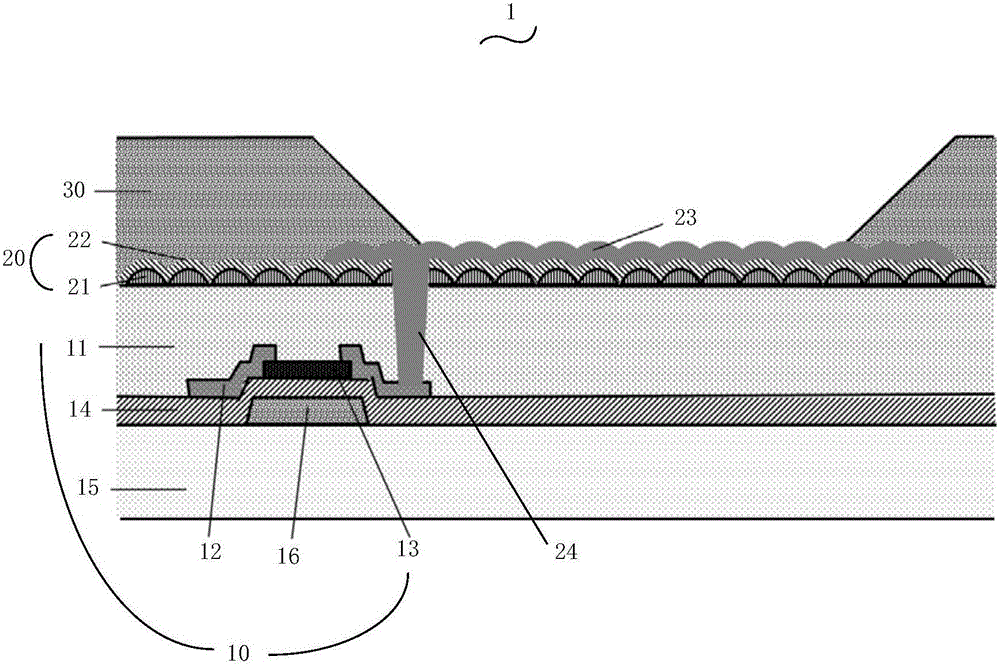

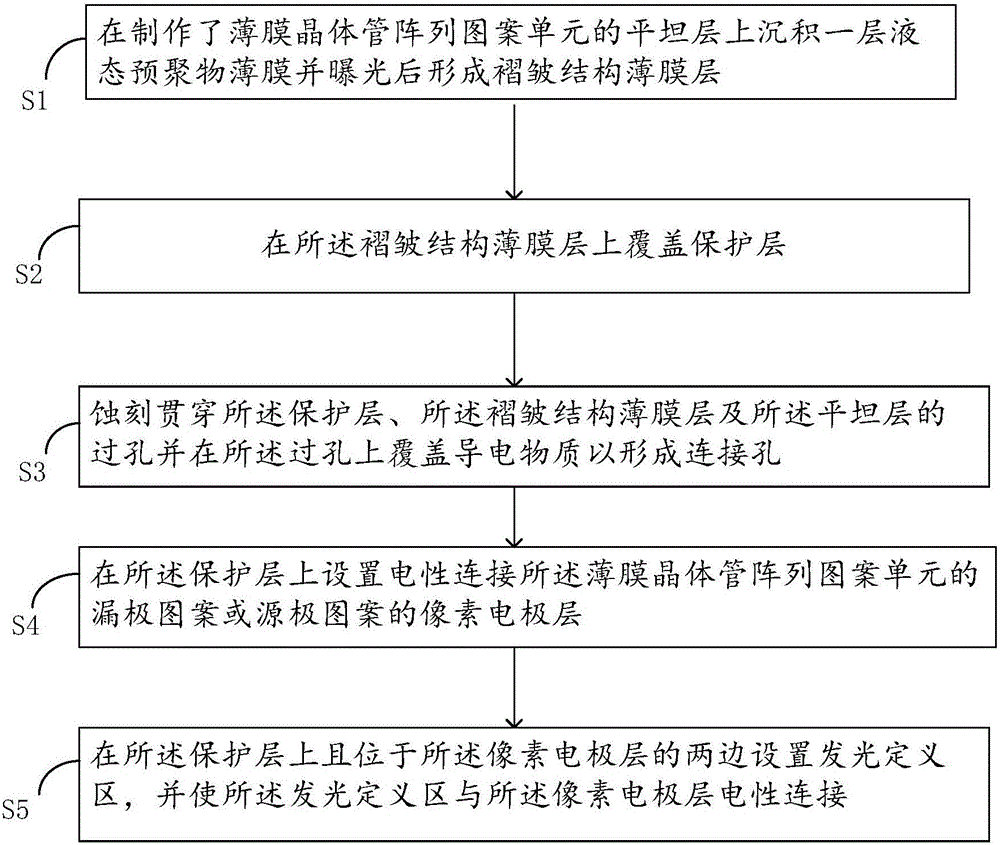

[0025] see figure 1 , is a structural schematic diagram of the pixel structure of the present invention. Such as figure 1 As shown, the pixel structure 1 includes a stacked thin film transistor array pattern unit 10 and a pixel pattern unit 20, the pixel pattern unit 20 includes a wrinkled thin film layer 21 on the thin film transistor array pattern unit 10, covering the The protective layer 22 on the wrinkled film layer 21 , the pixel electrode layer 23 located on the protective layer 22 and electrically connected to the thin film transistor array pattern unit 10 and the light-emitting defined area 30 .

[0026] Wherein, the thin film transistor array pattern unit 10 includes a flat layer 11 supporting the wrinkled thin film layer, a source pattern and a drain pattern 12 arranged on the flat layer 11 and spaced from each other, electrically connected to the The active layer 13 between the source pattern and the drain pattern 12, the gate insulating layer 14 covering the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com