Battery body of lithium battery and prepared first lithium battery

A technology of lithium batteries and battery cores, applied in the field of lithium primary batteries, can solve problems such as poor discharge performance, high heat generation, uneven current density distribution, etc., achieve great promotion value and solve the effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

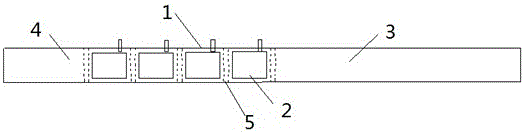

[0020] The assembly method of the diaphragm bag containing the positive electrode sheet provided in this embodiment: as figure 1 As shown, after the diaphragm bag 1 is folded in half, the first positive electrode sheet 2 is encapsulated, wherein the reserved long end 3 of the diaphragm bag is longer than the reserved short end 4 by at least three length units of the positive electrode sheet, and the reserved long end 3 is longer than the reserved short end 4. The length can be flexibly reserved according to the capacity design of the battery. It is used for encapsulating the last negative electrode sheet 8. Starting from the first seal 5, place the second positive electrode sheet 2 and continue encapsulating. At this time, the diaphragm The bag 1 has been folded in half when encapsulating the first positive electrode sheet 2, and then the third positive electrode sheet 2 is placed on the second seal 5, and the encapsulation is continued. According to this method, the positive e...

Embodiment 2

[0022] Another assembly method of the diaphragm bag containing the positive electrode sheet provided in this embodiment is: figure 1 , after folding the diaphragm bag 1 in half to equal length, seal the first positive electrode sheet 2, start from the first seal mark 5, place the second positive electrode sheet 2, and continue to seal, at this time, the diaphragm bag 1 is The first positive electrode sheet 2 has been folded in half during encapsulation, and then the third positive electrode sheet 2 is placed on the second seal 5, and the encapsulation is continued. According to this method, the positive electrode sheet 2 required in the assembly process is packaged. After sealing, obtain a diaphragm bag containing the positive electrode sheet.

Embodiment 3

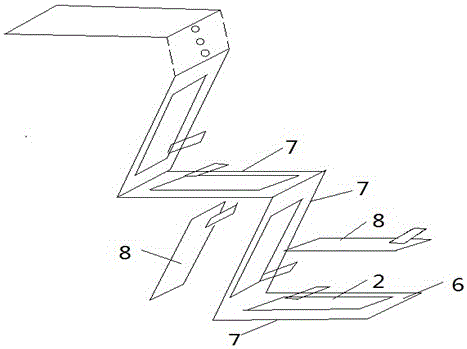

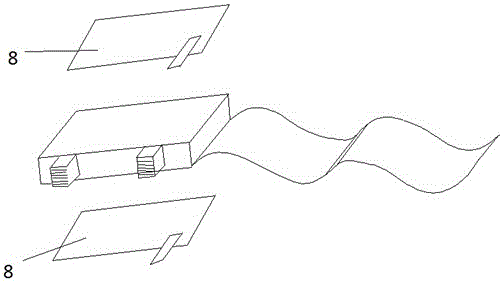

[0024] The assembly method of the lithium battery cell structure obtained by the embodiment 1 and the embodiment 2 provided in this embodiment is as follows figure 2 As shown, polyvinylidene fluoride 6 is applied around the upper seal of the first positive electrode sheet 2 of the diaphragm bag containing the positive electrode sheet, and the position corresponding to the first positive electrode sheet 2 is above the first positive electrode diaphragm bag 7 Put the first negative electrode sheet 8, fold and seal the first negative electrode sheet 8 with the first positive electrode diaphragm bag 7 and the second positive electrode diaphragm bag 7, and then place around the seal marks on both sides of the second positive electrode diaphragm bag 7 Apply polyvinylidene fluoride 6, fold and seal the second positive electrode diaphragm bag 7 and the third positive electrode diaphragm bag 7 in half, and seal the second negative electrode sheet 8 in half. According to this method, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com