Compact five-port structure applied to three-path high-efficiency high-isolation power synthesis

A high-isolation, five-port technology, applied in the field of microwave passive devices, can solve the problems of difficult design of two-way power splitters, failure to meet cross-sectional size requirements, isolation and return loss between composite ports cannot meet requirements, etc. , to achieve the effect of low return loss and high isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

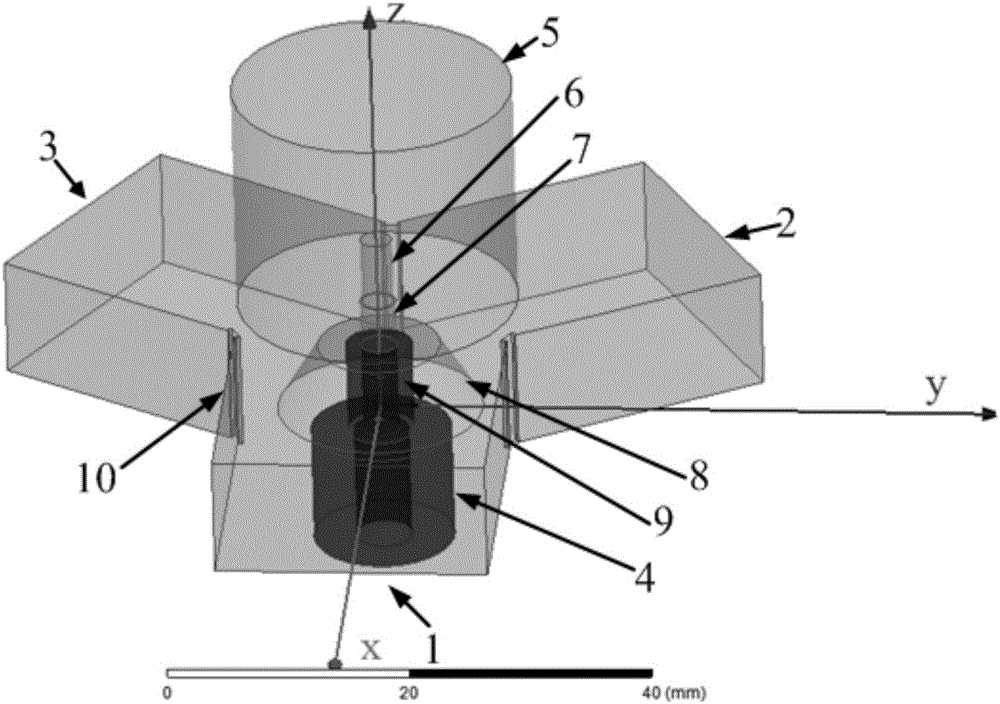

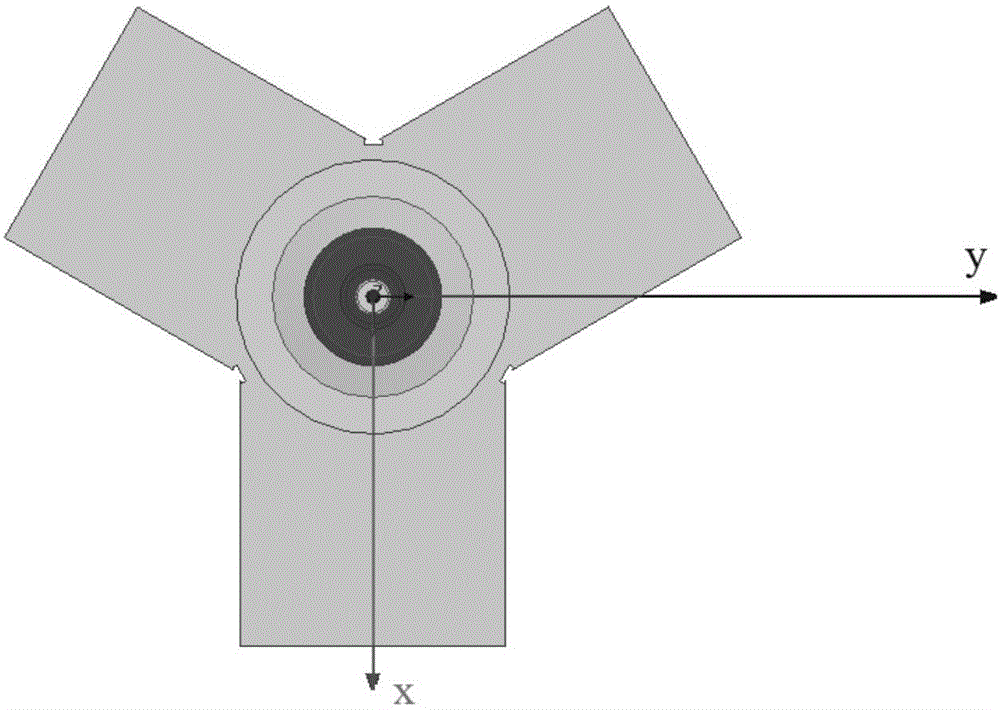

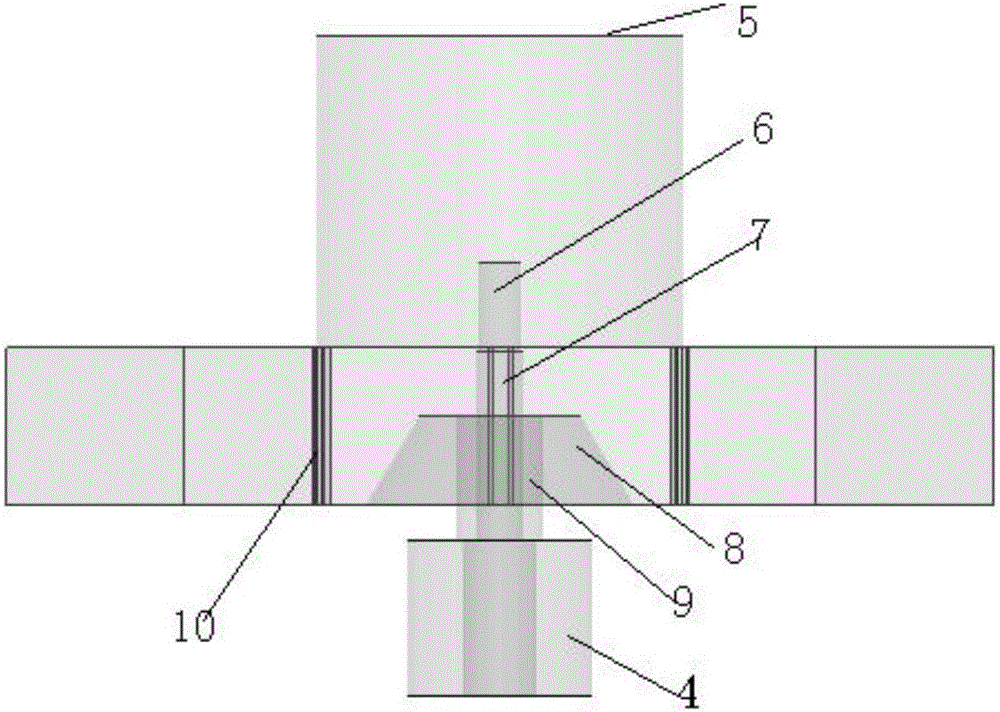

[0053] The present invention is applied to a compact five-port structure for three-way high-efficiency high-isolation power synthesis, and its structure is composed of: the first, second, and third rectangular waveguides intersect at an angle of 120°, and the E-plane of the circular waveguide is coupled to the three rectangular waveguides The top plane of the intersecting area, the bottom surface of the intersecting area of the three rectangular waveguides is connected with the conical protrusion 8, and the top plane of the conical protruding 8 is sequentially connected to the first metal probe 7 and the second metal probe in the direction of the circular waveguide. The needle 6, the top plane is connected to the dielectric first dielectric coaxial waveguide and the second dielectric coaxial waveguide in sequence in the direction opposite to the circular waveguide, and the three insertion waveguide ridges 10 are located at the intersection of the three rectangular waveguides. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com