Novel bending micro-strip ridge substrate integrated gap waveguide structure

A gap waveguide and bending technology, applied in the field of electronics, can solve problems such as no public reports, and achieve the effect of solving discontinuity problems, stable structure, and good transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

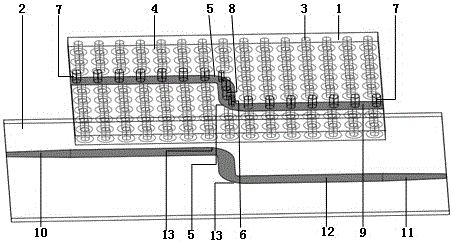

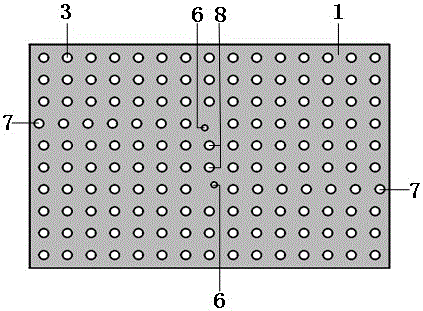

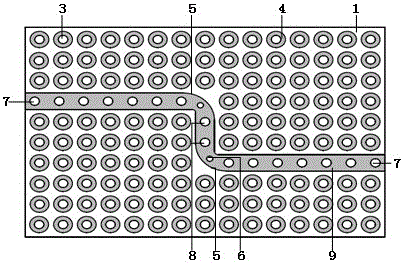

[0028] Such as Figure 1-6 As shown, a novel curved microstrip ridge substrate integrated gap waveguide structure, including: a via layer dielectric plate 1, a gap layer dielectric plate 2, wherein:

[0029] A metal layer is printed on the upper surface of the via layer dielectric board 1; a first arc-curved microstrip line 9 is arranged laterally in the middle of the lower surface, and the first microstrip line 9 adopts an arc-curved design. The first via hole 7 is provided, the two circular arc curved sections 5 are respectively provided with micro via holes 6, and the vertical section between the two arc curved sections 5 is provided with a second through hole 8, and the diameter of the micro via hole 6 is smaller than that of the first via hole. The first via hole 7 is small, the arc bending design and the via hole 6 solve the probl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com