Multi-stage gas switch with corona gap

A gas switch and gap technology, applied in the direction of electrical components, circuits, spark gaps, etc., can solve problems such as complex structure of the switch system, achieve the effect of improving insulation recovery speed, increasing operating frequency, and suppressing pre-breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

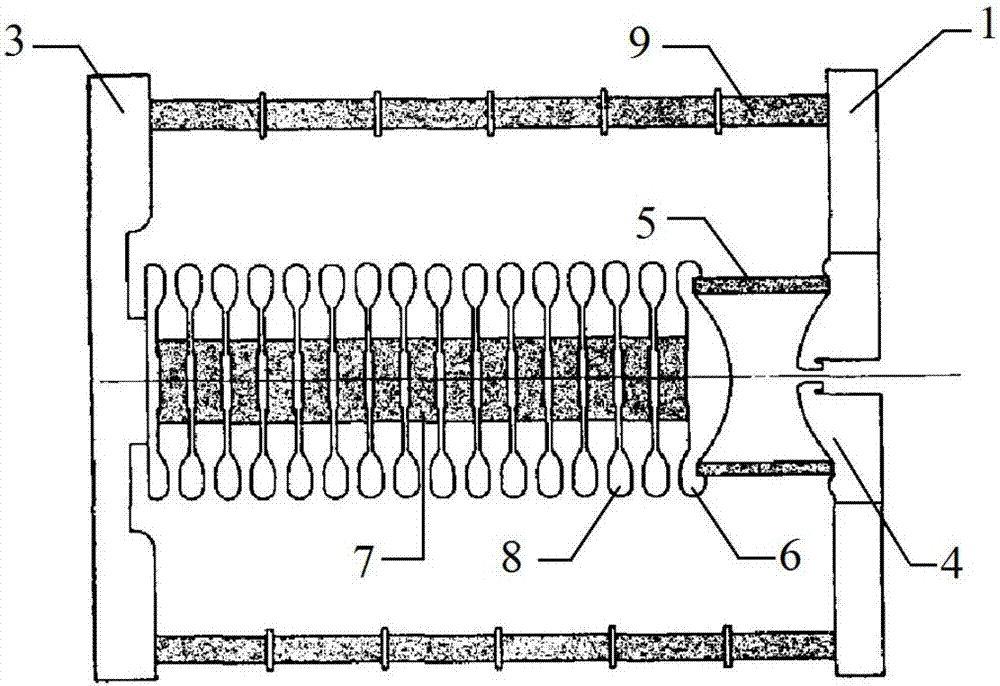

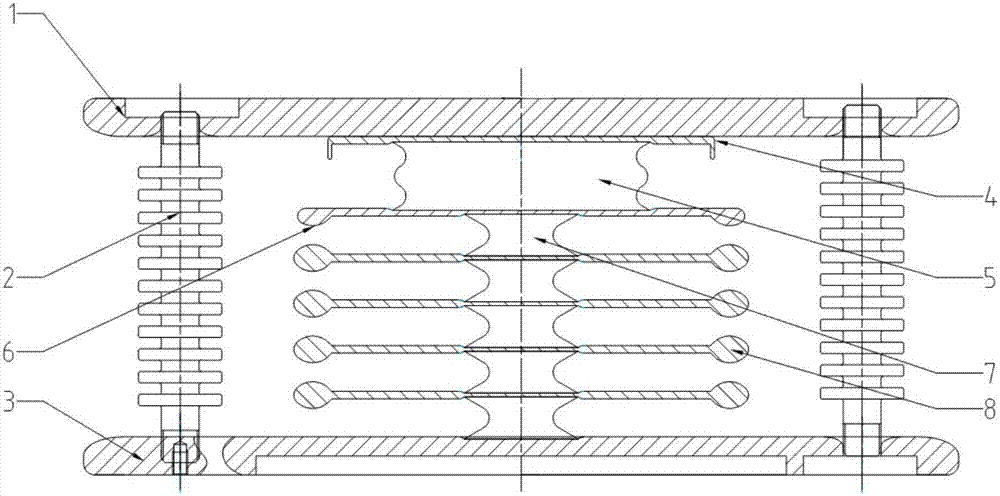

[0015] The following examples refer to Figure 2-3 .

[0016] The multi-stage gas switch with corona gap of the present invention includes a head-end equalizing plate 1, a pull rod 2, an end equalizing plate 3, a first electrode 4, a first insulator 5, a second electrode 6, a second insulator 7 and a third Electrode 8. The first electrode 4 is in the shape of a ring blade, the second electrode 6 is a plate electrode, and the third electrode 8 is a disk electrode. The first electrode 4 and the second electrode 6 are placed opposite to each other, and they are supported by the first insulator 5 to form a corona gap; every two third electrodes 8 are placed opposite to each other and supported by the second insulator 7 to form an overvoltage breakdown gap. A uniform electric field can be formed between the head-end pressure equalizing plate 1 and the end pressure equalizing plate 3, which avoids the interference of the external electric field to the inside. The pressure equaliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com