Composite hydrophilic/hydrophobic enhanced boiling heat transfer sheet with columnar microstructure

A technology of enhanced boiling and heat exchange fins, which is applied in the direction of cooling/ventilation/heating transformation, structural parts of electrical equipment, modification using liquid cooling, etc., can solve the problems of boiling enhanced heat transfer surface properties change, etc., to delay dry burning Crisis, reliable operating principle, and the effect of high-efficiency heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments and with reference to the accompanying drawings.

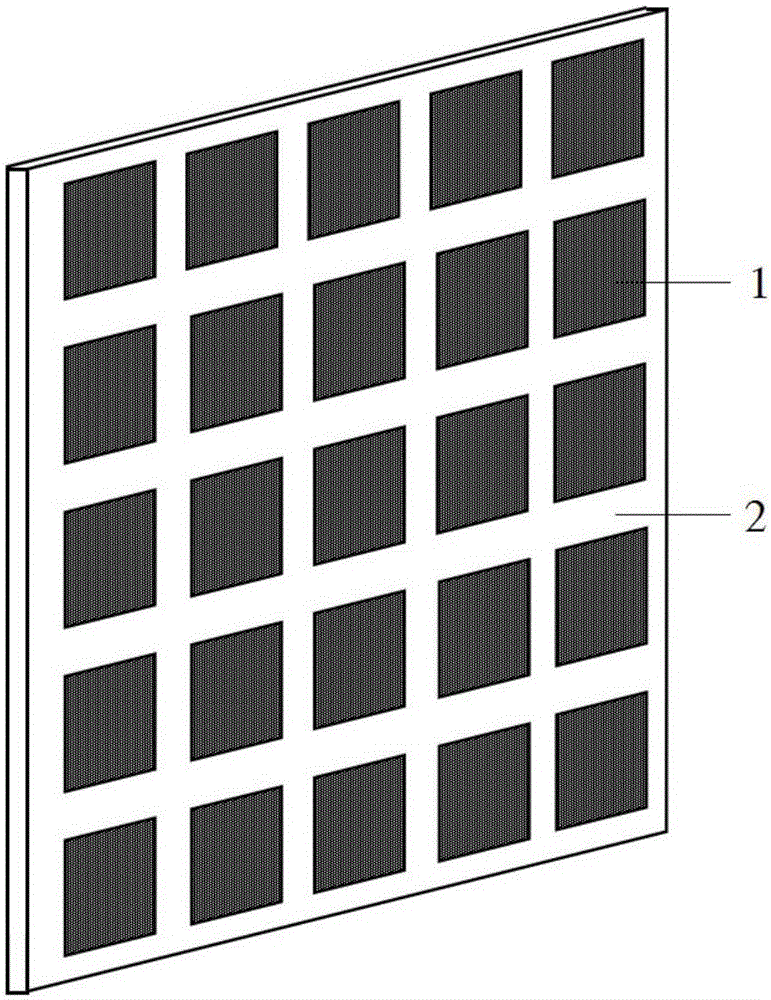

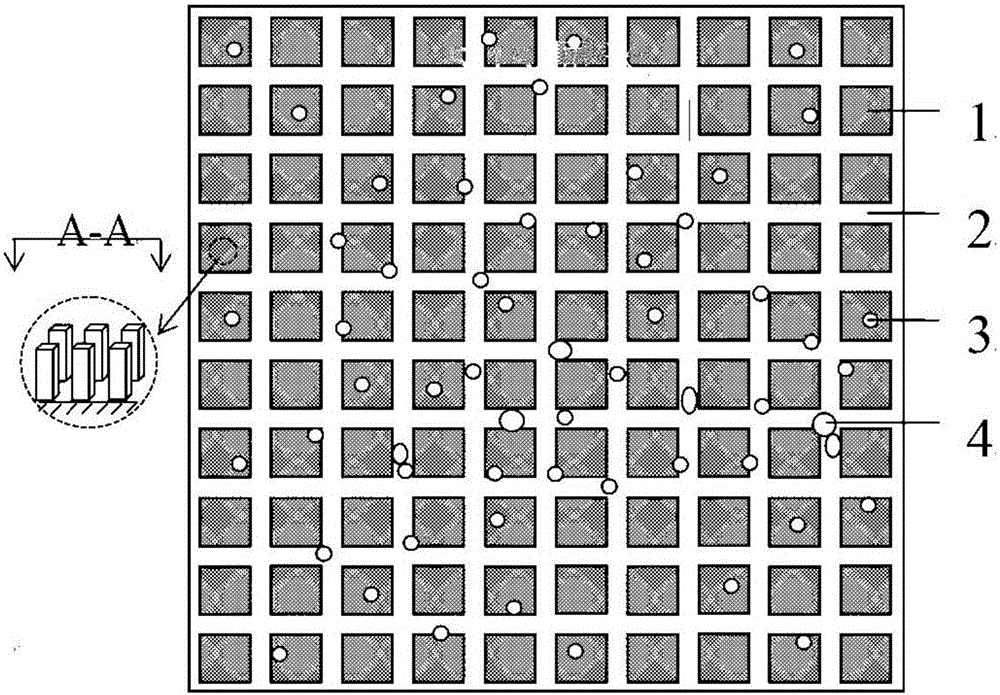

[0020] A hydrophilic / hydrophobic enhanced boiling heat transfer sheet with composite columnar microstructures comprises columnar microstructure hydrophobic regions 1 and smooth hydrophilic channels 2, and the hydrophobic regions 1 are interspersed and separated by smooth channels to form hydrophobic arrays.

[0021] The columnar microstructure hydrophobic region 1 is composed of a columnar microstructure array with a height and side length on the order of tens of microns formed by dry corrosion. The static contact angle measured with deionized water is 135°. The columnar microstructure can trap non-condensable gases and provide the nucleate boiling vaporization core to reduce the superheat of the wall at the boiling initiation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com