Fabricating full color three-dimensional objects

A three-dimensional object, full-color technology, applied in manufacturing, manufacturing tools, additive manufacturing, etc., can solve problems such as hindering the manufacture of full-color three-dimensional objects, and inability to convert full-color models into machine instructions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

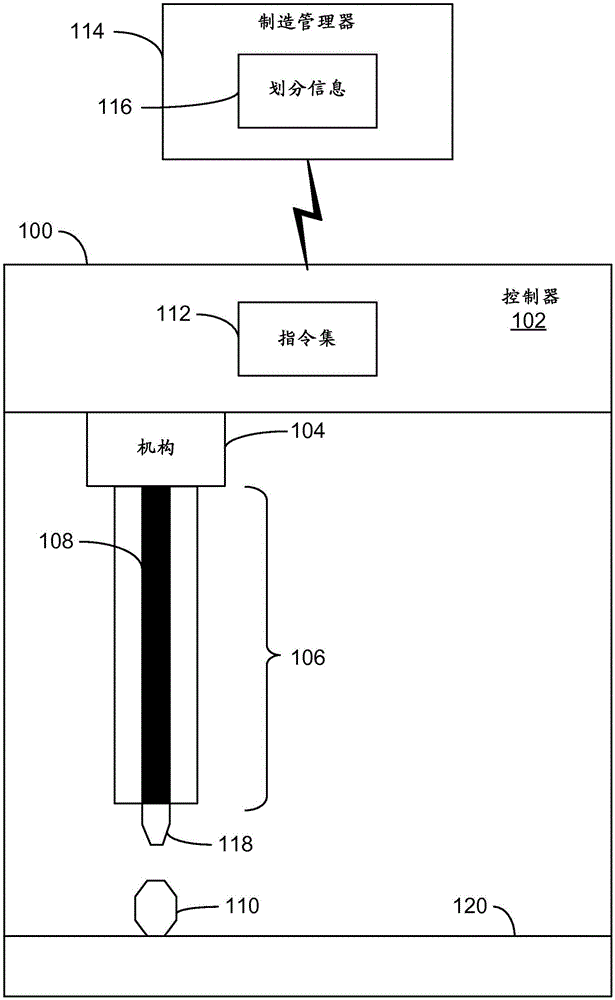

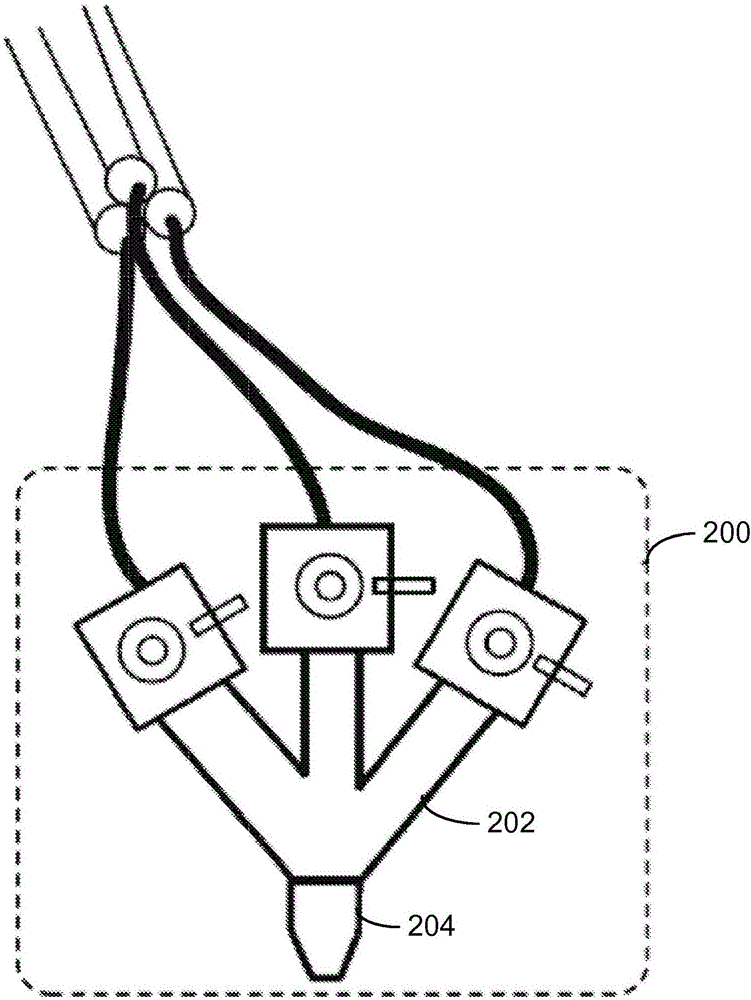

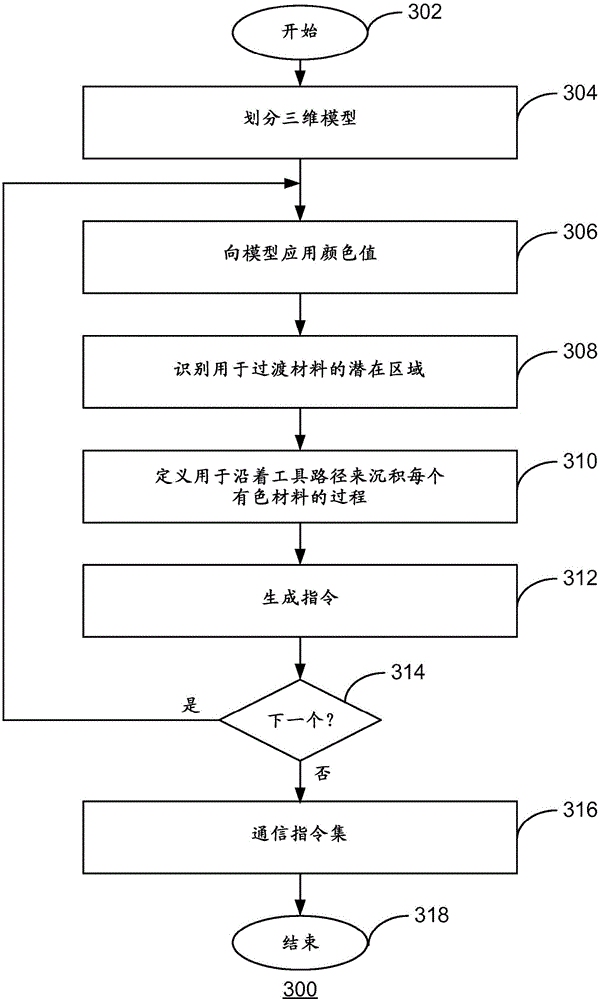

[0029] Embodiments described herein generally relate to a fabrication manager configured to generate a set of instructions that, when executed, cause a fabrication device to fabricate a full-color three-dimensional object using a plurality of colored materials. More specifically, the instruction set describes the exact tool paths and tool heads that the tool heads of the manufacturing equipment will follow to create a full-color three-dimensional object, as well as the appropriate times to switch colors and the amount of material to be deposited at each point in time. A tool head may include a head with a nozzle and an assembly of motors, which may be local or remote. Additionally, in some embodiments, the tool head may include multiple heads, each head having its own nozzle. In various embodiments, the manufacturing manager generates a set of instructions that enables smoothing on the exterior of the object to be optimized and material usage to be minimized when switching col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com