Preparation method of additive-free yoghourt

A technology of additives and yogurt, which is applied in the field of preparation of zero-additive yogurt, and can solve the problem of high additive content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific examples.

[0024] 1. Yogurt production process

[0025] 1. Preparation of working starter

[0026] Fresh milk—sterilization—cooling—inoculation (Streptococcus thermophilus, Lactobacillus bulgaricus, Lactobacillus acidophilus and Bifidobacterium)—fermentation culture—working starter;

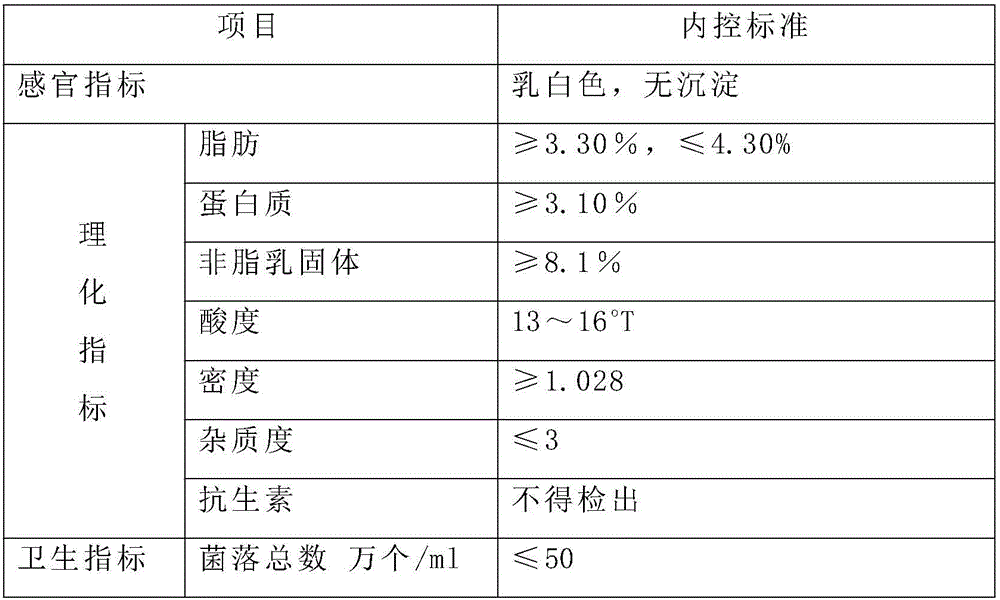

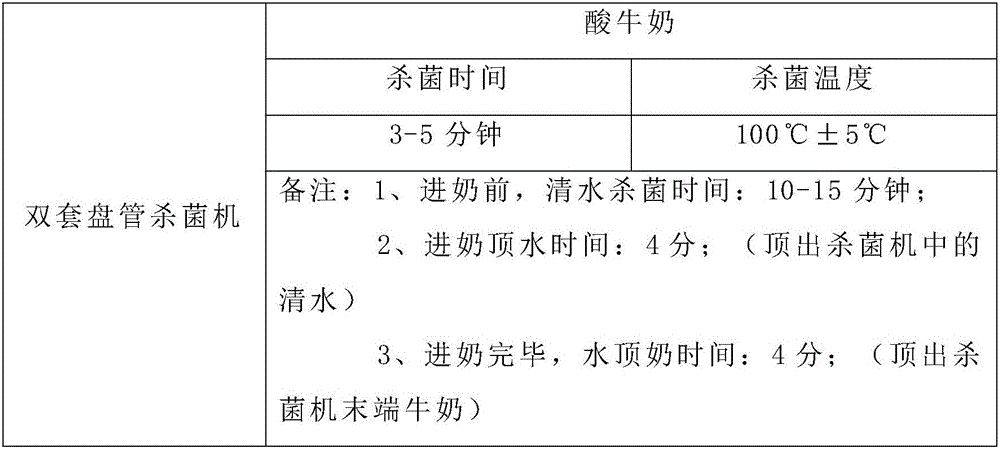

[0027] 2. Raw milk—testing—measurement—separation and purification—ingredients—homogenization—sterilization—cooling—inoculation—fermentation—demulsification and stirring—filling—testing—storage.

[0028] 2. Process requirements

[0029] (1) Preparation of working starter

[0030] 1. Container

[0031] 1) The cleaning of the working starter culture tank and seed tank is strictly in accordance with the CIP cleaning requirements to remove residual proteins, fats, salts and other residual substances. CIP is a commonly used technology at present, so I will not repeat it here.

[0032] 2) Disinfection of wor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com