Preparation method of carbon dioxide-responsive membrane

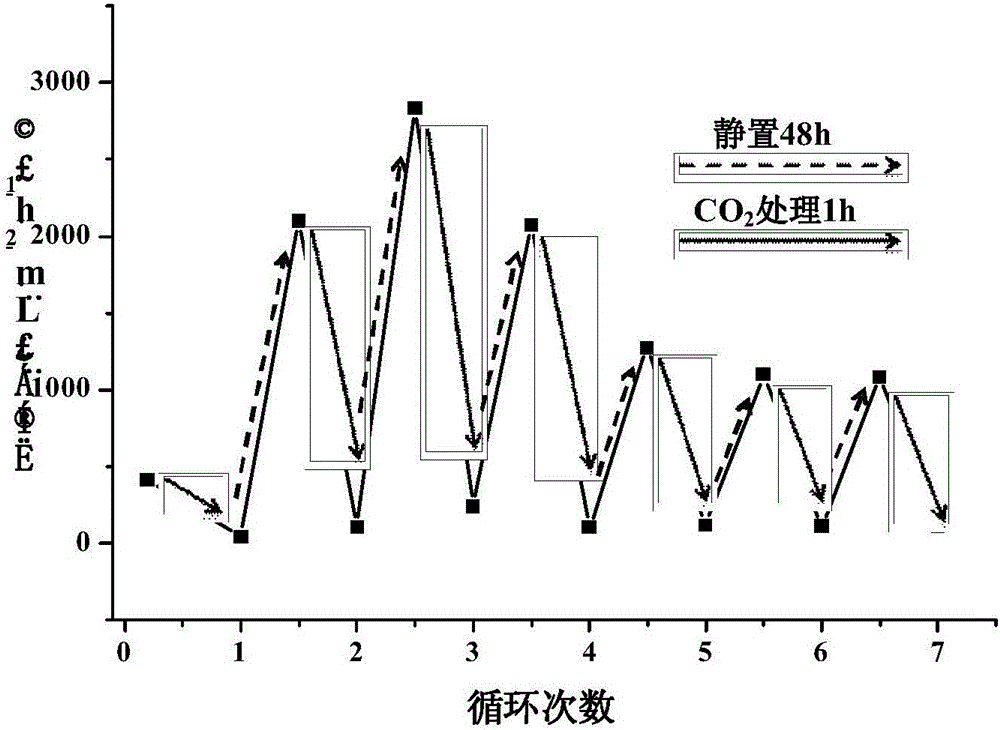

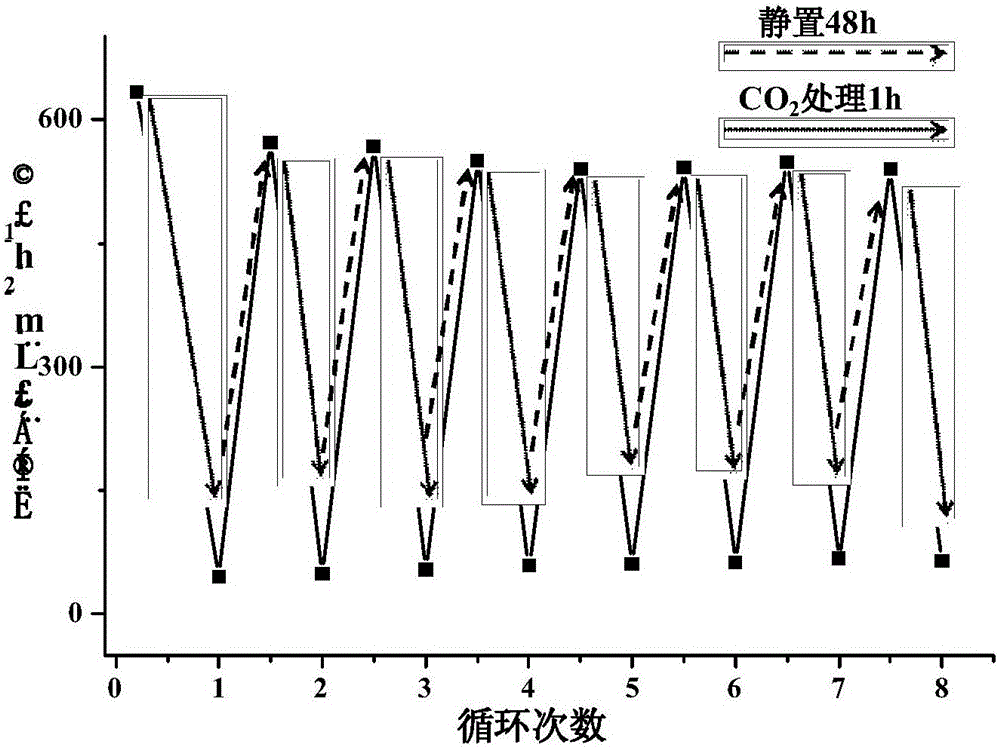

A carbon dioxide, responsive technology, applied in the field of preparing carbon dioxide responsive membrane, can solve the problems of cumbersome process, high energy consumption and high cost of direct scraping method and grafting method, and achieve the effect of excellent recyclability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At room temperature, put 2g of diethylaminoethyl methacrylate, 0.1g of N,N'-methylenebisacrylamide, 0.16g of azobisisobutylamidine hydrochloride, and 38g of deionized water in a 100ml round bottom flask Mix evenly in the medium, pass nitrogen to remove oxygen for 0.5h, heat up to 70°C, and react with magnetic stirring for 6h to obtain carbon dioxide responsive microgel emulsion.

[0026] Dilute 10 mL of the obtained carbon dioxide-responsive microgel emulsion with 490 mL of deionized water to obtain an 8 mg / L carbon dioxide-responsive microgel dispersion. Put a 0.45um cellulose ester microporous membrane (Shanghai Xingya Purification Material Factory Q / IEFJ01-1997, diameter 47mm) into the filter device, and use 500mL 8mg / L carbon dioxide responsive microgel under the negative pressure of 0.09MPa The dispersion was filtered for 20 minutes, and finally the membrane was reversed in a filter device and washed with 100 ml of deionized water to obtain a carbon dioxide respons...

Embodiment 2

[0030] At room temperature, put 2g of diethylaminoethyl methacrylate, 0.1g of N,N'-methylenebisacrylamide, 0.16g of azobisisobutylamidine hydrochloride, and 38g of deionized water in a 100ml round bottom flask Mix evenly in the medium, pass nitrogen to remove oxygen for 0.5h, heat up to 70°C, and react with magnetic stirring for 6h to obtain carbon dioxide responsive microgel emulsion.

[0031]Dilute 10 mL of the obtained carbon dioxide-responsive microgel emulsion with 490 mL of deionized water to obtain an 8 mg / L carbon dioxide-responsive microgel dispersion. A 0.45um polyethersulfone microporous membrane (Merck Milipore HPWP04700, 47mm in diameter) was packed into a filter device, and filtered with 500mL 8mg / L carbon dioxide responsive microgel dispersion for 20min under a negative pressure of 0.09MPa, and finally The membrane was reversely placed in a filter device and washed with 100 ml of deionized water to obtain a carbon dioxide responsive membrane.

[0032] Under a n...

Embodiment 3

[0035] At room temperature, put 3g of diethylaminoethyl methacrylate, 0.1g of N,N'-methylenebisacrylamide, 0.32g of azobisisobutylamidine hydrochloride, and 38g of deionized water in a 100ml round bottom flask Mix evenly in the medium, pass nitrogen to remove oxygen for 0.5h, heat up to 70°C, and react with magnetic stirring for 6h to obtain carbon dioxide responsive microgel emulsion.

[0036] Dilute 20 mL of the obtained carbon dioxide-responsive microgel emulsion with 480 mL of deionized water to obtain a 16 mg / L carbon dioxide-responsive microgel dispersion. A 0.45um polypropylene microporous membrane (Haining Taoyuan Medical Chemical Instrument Factory, 47mm in diameter) was put into the filter device, and filtered with 500mL 16mg / L carbon dioxide responsive microgel dispersion for 20min under a negative pressure of 0.09MPa, Finally, the membrane was reversely placed in a filter device and washed with 100 ml of deionized water to obtain a carbon dioxide responsive membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Z-average particle size | aaaaa | aaaaa |

| Z-average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com