Automatic-feeding thin-walled tube laser cutting machine with graph guiding function

A laser cutting machine, automatic feeding technology, applied in laser welding equipment, tubular items, applications, etc., can solve the problems of low processing efficiency and cumbersome operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

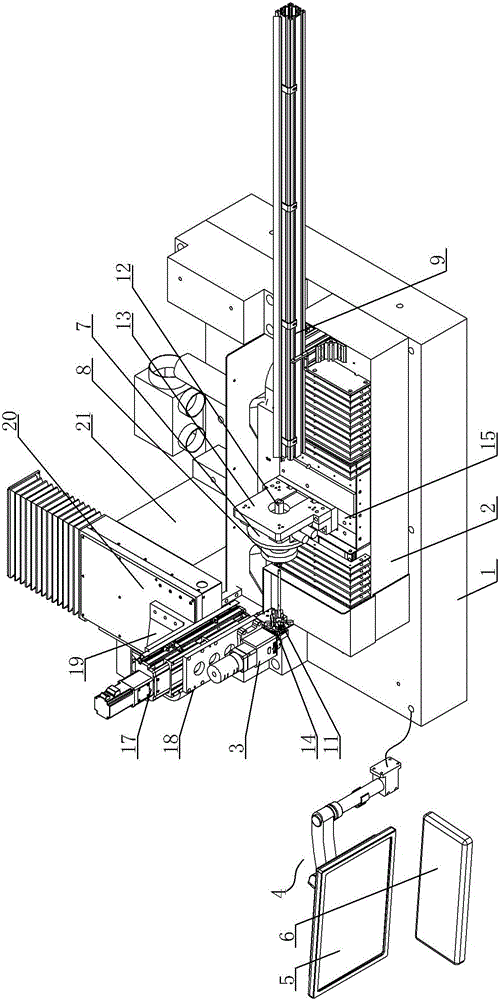

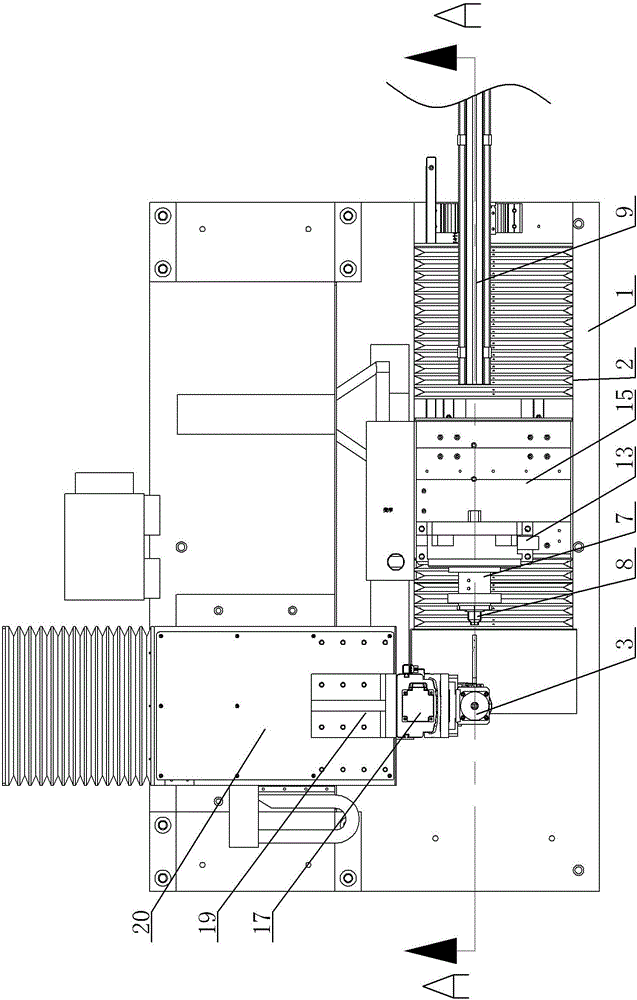

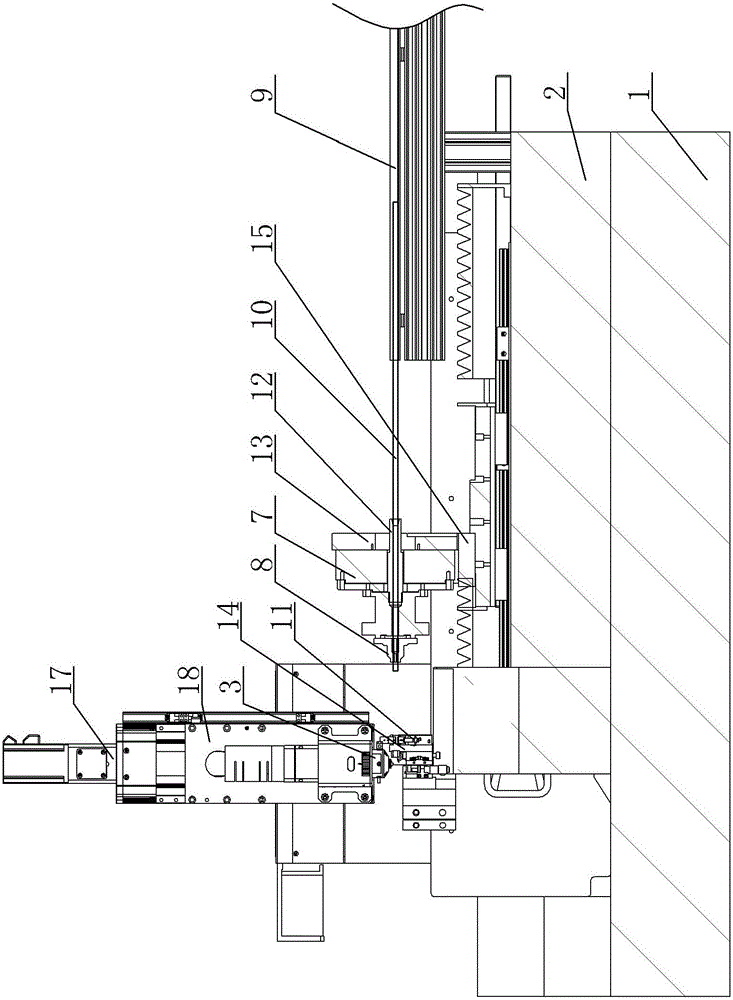

[0018] Automatic feeding thin wall tube laser cutting machine with graphic guide function, see Figure 1 ~ Figure 3 : It comprises machine base 1, and machine base 1 is provided with cutting machine main engine (not drawn in the figure, belongs to existing mature technology), and machine base 1 upper end surface is provided with console 2, and one end of console 2 is provided with laser cutting machine. The head 3 also includes an external computer 4. The external computer 4 includes a display 5 and a keyboard 6. The host of the external computer 4 is connected to the host of the cutting machine through a data cable. Graphics operation software, the graphics operation software expands the three-dimensional thin-walled tube to form a planar view and sets the corresponding processing pattern. The laser cutting head 3 can move in the Z-axis and Y-axis. The R-axis rotary motor 7 that moves axially, the output end of the R-axis rotary motor 7 towards the laser cutting head 3 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com