Composite tool head for machining energetic materials

A technology of machining and composite tools, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low yield and process dispersion, and achieve the effect of convenient use, elimination of the influence of machining accuracy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

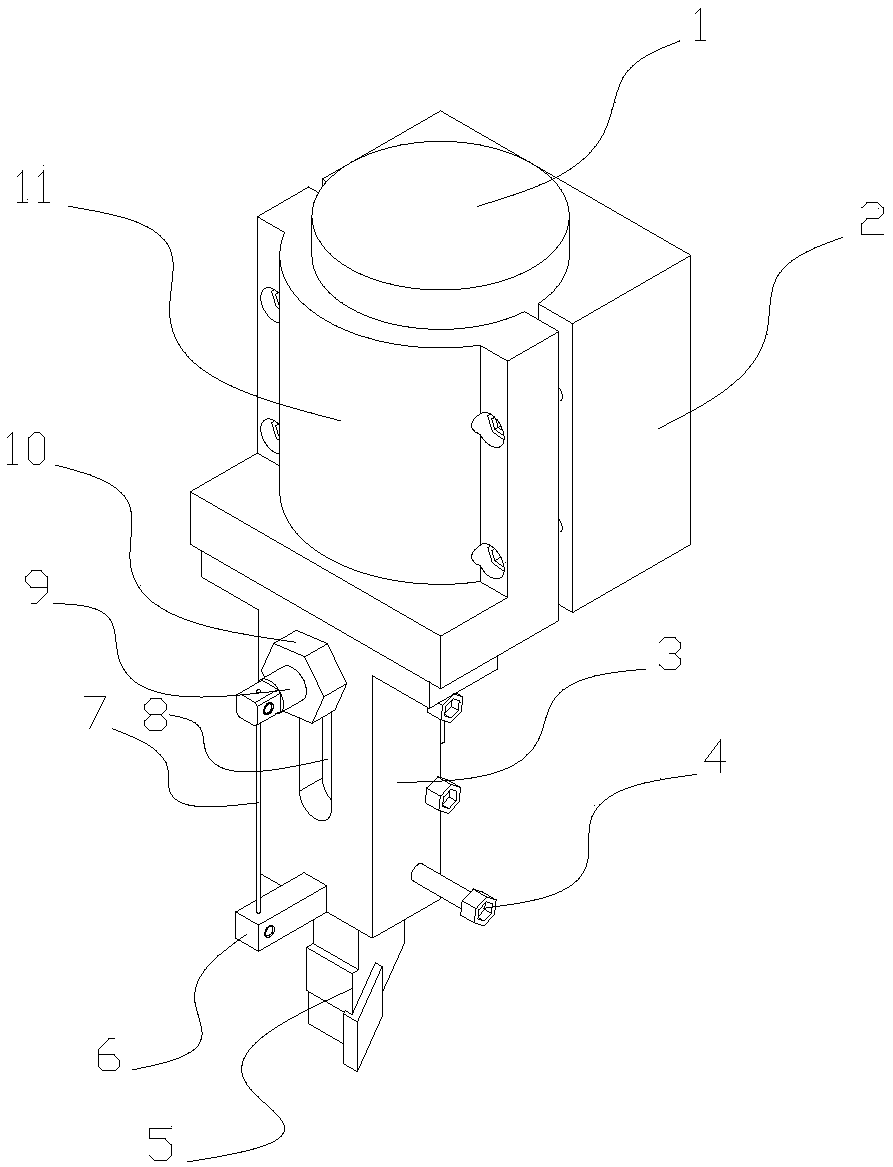

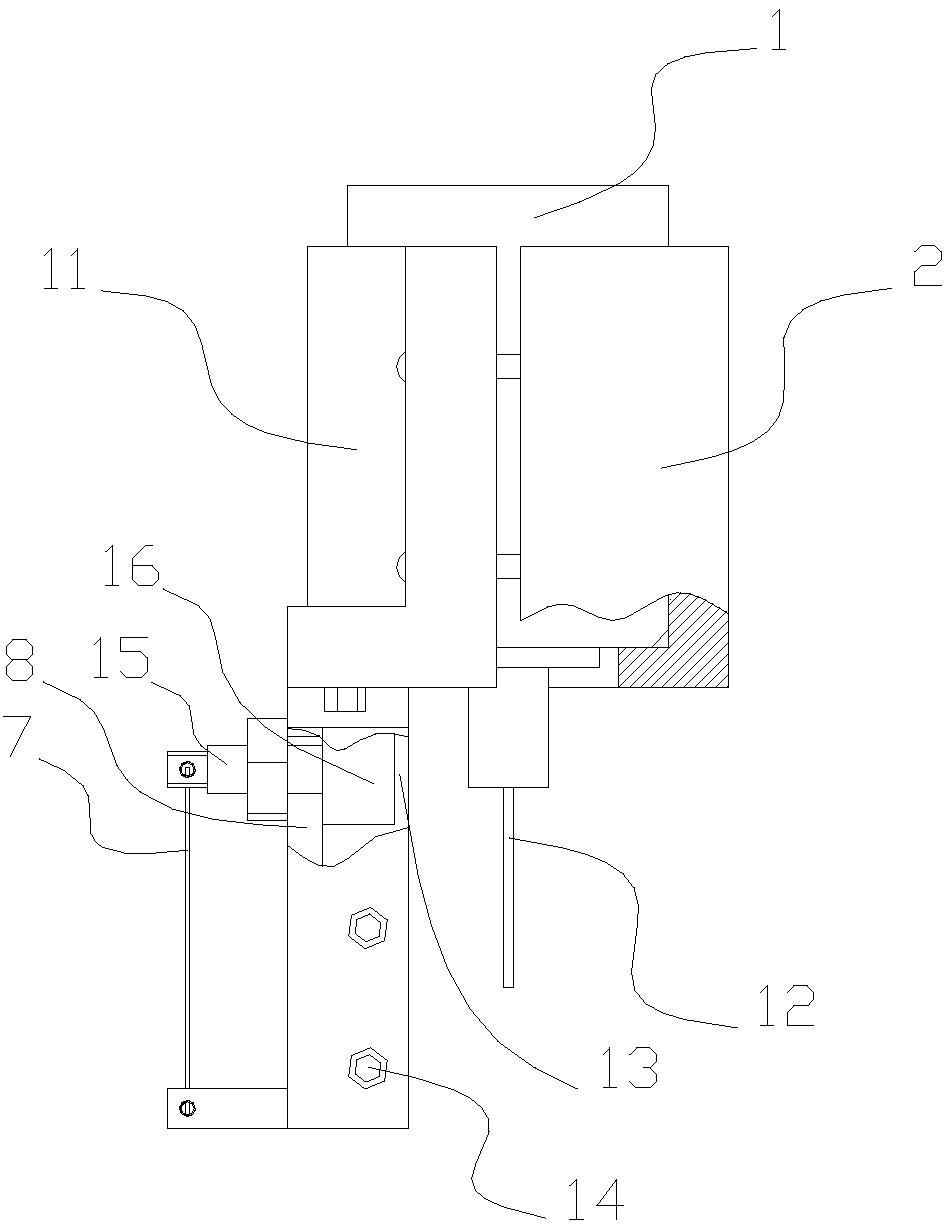

[0026] The present invention will be further explained below in conjunction with the drawings.

[0027] Such as figure 1 with figure 2 A composite tool head suitable for machining energetic materials is shown. It includes a spindle 1. An outer tool seat 11 and an inner tool seat 2 are installed on both sides of the spindle 1 respectively. The outer tool seat 11 and the inner tool seat 2 pass through bolts. The connection is installed on both sides of the spindle 1. When the outer tool holder 11 and the inner tool holder 2 are connected, the inner hole between them is aligned with the marking line on the end face of the spindle 1 to ensure the accuracy of axis rotation. The outer tool holder 11 and the inner tool The L-shaped positioning surface of the seat 2 at the seat mouth (ie the edge position of the lower end of the outer tool holder 11 and the inner tool holder 2) and the end surface of the spindle 1 can realize the axial positioning of the tool head. The lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com