A bill and file binding machine for office supplies

A technology for office supplies and binding machines, which is applied in binding and other directions, can solve the problems of shortening and the service life of the indenter module is easily damaged, and achieves the effect of reducing the damage rate, good assembly and maintenance process, and reducing personnel participation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

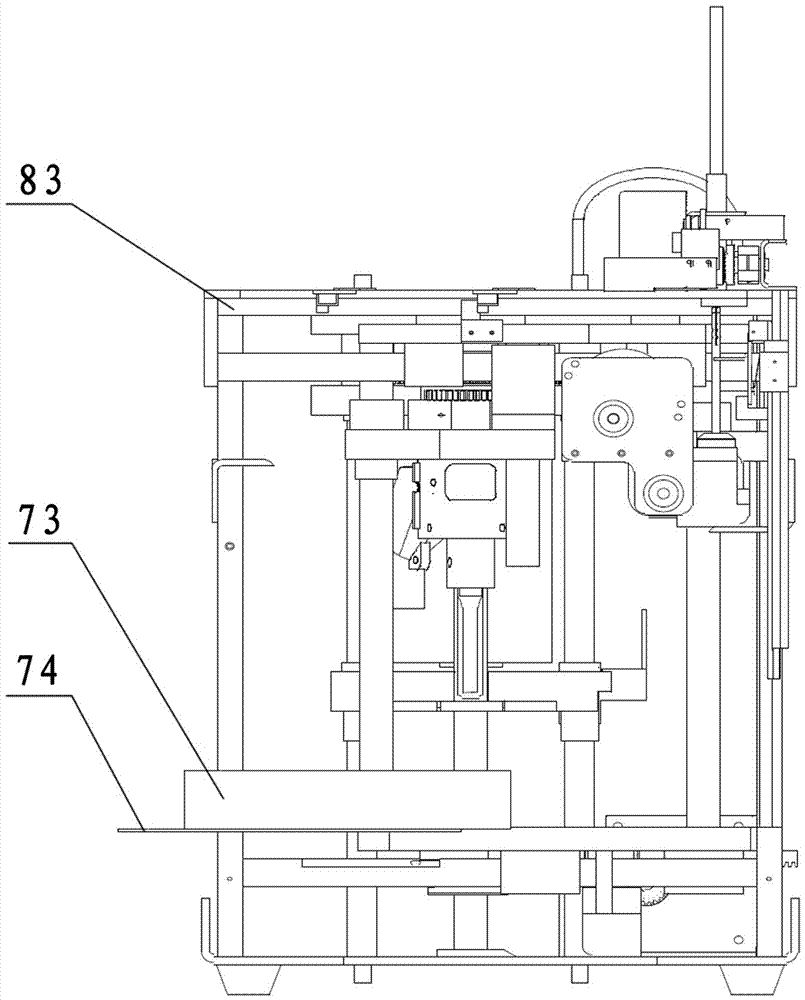

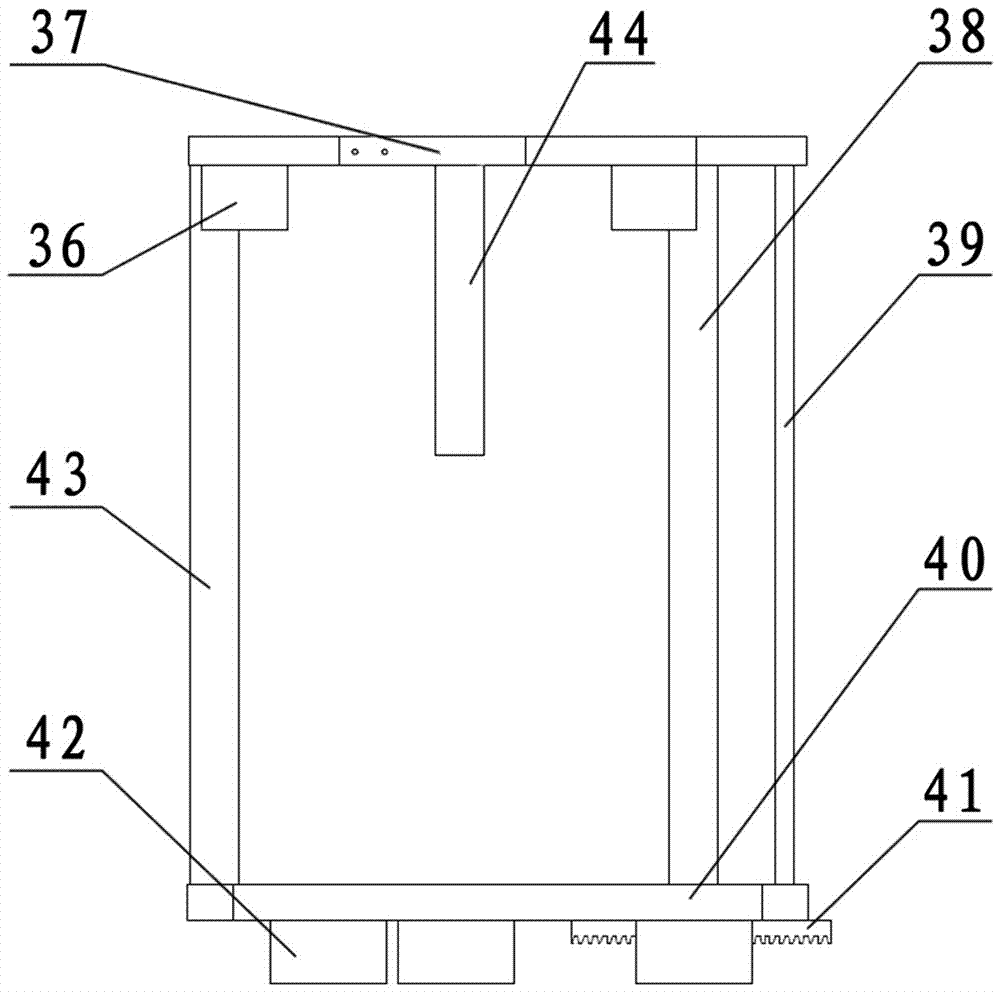

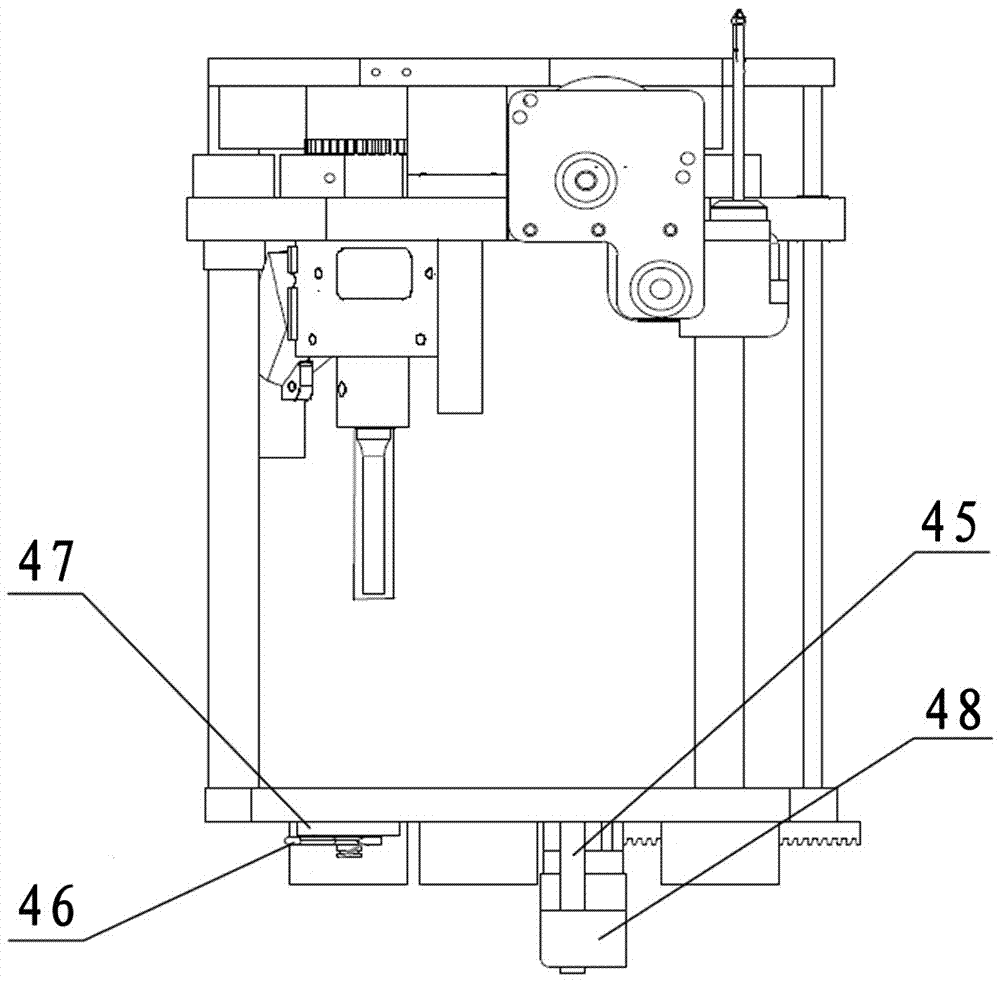

[0037] Such as figure 1 , figure 2 , image 3 As shown, the binding machine of the present invention is composed of an upper movable plate 37, a lower movable plate 40 and a first guide rod 38, a second guide rod 39 and a third guide rod 43 arranged between the upper movable plate 37 and the lower movable plate 40 make up a rectangular moving frame ( figure 2 ). On the upper moving plate 37, the upper sliding sleeve 36 and the fourth guide rod 44 extending downward are connected, and on the lower moving plate 40, the lower sliding sleeve 42 and the horizontal rack 41 are connected. Mobile frame is arranged in frame 83 (frame, also claims complete machine frame) ( figure 1 ), on the moving frame there are upper pressure riveting ironing head module, punching module, conductive rubber module and lower pressure riveting ironing head module ( image 3 ), the frame 83 is provided with working mechanisms such as a working panel 74, a binding tube in-position detection module,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com