Temperature-sensitive nanocapsules and preparation method thereof

A nanocapsule and temperature-sensitive technology, applied in the field of temperature-sensitive nanocapsules and its preparation, can solve the problems of high embedding rate, achieve high embedding rate, good biocompatibility, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

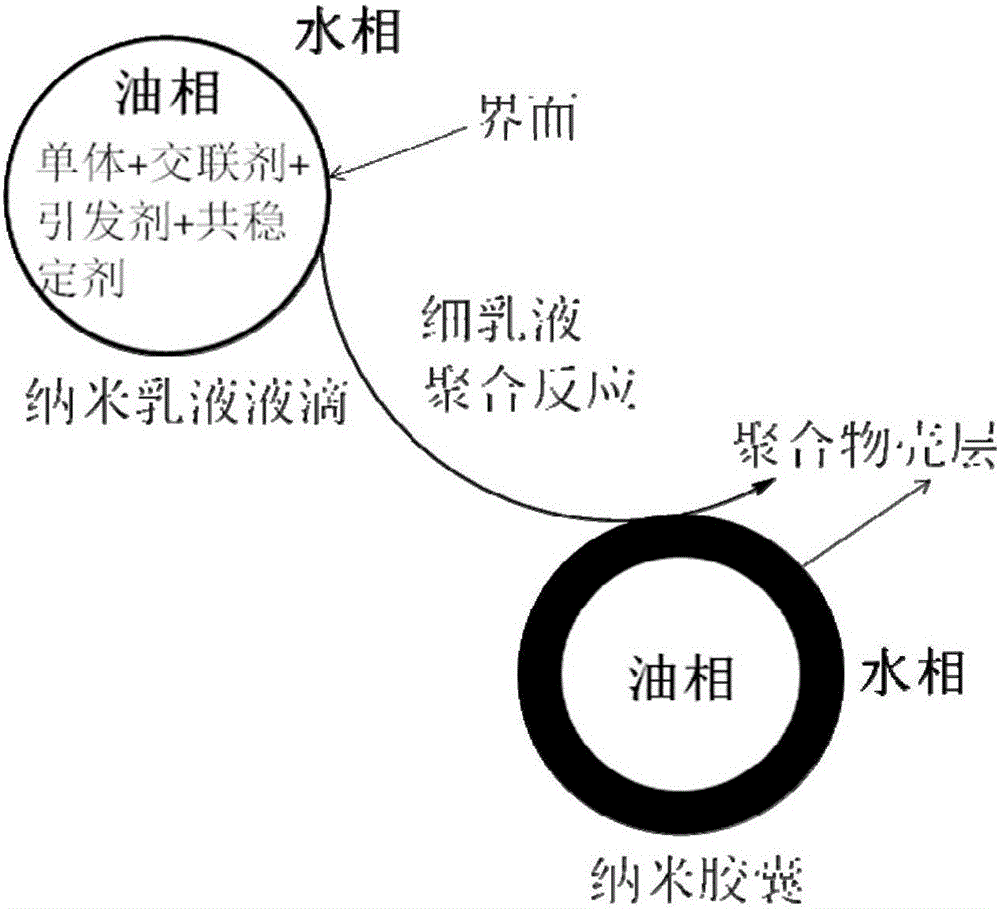

[0054] A preparation method of temperature-sensitive nanocapsules, the preparation steps are:

[0055] (1) Preparation of emulsifier aqueous solution: 1.5 parts of sodium dodecylsulfonate and 10 parts of deionized water were mixed to obtain an aqueous phase;

[0056] (2) Mix 10 parts of core material, 6 parts of N,N-diethylacrylamide, 6 parts of N,N-dimethylacrylamide, 1 part of ethylene glycol dimethacrylate, 0.1 part of azobisiso Butyronitrile and 1 part of hexadecane are mixed and stirred evenly to obtain an oil phase;

[0057] (3) adding the water phase to the oil phase, shearing at a shear rate of 6000rpm for 3min to form a microemulsion, and then ultrasonicating at a 50% amplitude for 10min to form a nanoemulsion;

[0058] (4) After the nanoemulsion is formed, the nitrogen protection is continued until the end of the reaction, and the temperature-sensitive nanocapsules are obtained by reacting at 40° C. for 3 hours.

[0059] When the core material is octocrylene, benzo...

Embodiment 6~10

[0062] A preparation method of temperature-sensitive nanocapsules, the preparation steps are:

[0063] (1) Prepare emulsifier aqueous solution: mix 2 parts of sodium dodecylsulfonate and 15 parts of deionized water to obtain an aqueous phase;

[0064] (2) 20 parts of core material, 8 parts of N,N-diethylacrylamide, 6 parts of N,N-dimethylacrylamide, 5 parts of 1,4-butylene glycol dimethacrylate, 0.2 parts Azobisisobutyronitrile and 1.1 parts of hexadecane are mixed and stirred evenly to obtain an oil phase;

[0065] (3) adding the water phase to the oil phase, shearing at a shear rate of 6500rpm for 4min to form a microemulsion, and then ultrasonically forming a nanoemulsion with a 50% amplitude for 12min;

[0066] (4) After the nanoemulsion is formed, the nitrogen gas protection is continued until the reaction is completed, and the temperature-sensitive nanocapsules are obtained by reacting at 42° C. for 4 hours.

[0067] When the core material is mint oil, rose essence, le...

Embodiment 11~15

[0070] A preparation method of temperature-sensitive nanocapsules, the preparation steps are:

[0071] (1) Preparation of emulsifier aqueous solution: 3 parts of sodium dodecylsulfonate and 20 parts of deionized water were mixed to obtain an aqueous phase;

[0072] (2) Mix 50 parts of water clear lotus essence, N,N-diethylacrylamide, N,N-dimethylacrylamide, 2 parts of 1,6-hexanediol dimethacrylate, 0.3 parts of azo Diisobutyronitrile and 1.2 parts of hexadecane are mixed and stirred evenly to obtain an oil phase;

[0073] (3) adding the water phase to the oil phase, shearing at a shear rate of 7000rpm for 5min to form a microemulsion, and then ultrasonicating at a 50% amplitude for 15min to form a nanoemulsion;

[0074] (4) After the nanoemulsion is formed, the nitrogen protection is continued until the reaction is completed, and the temperature-sensitive nanocapsules are obtained by reacting at 45° C. for 3 hours.

[0075] When the parts by weight of N,N-diethylacrylamide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

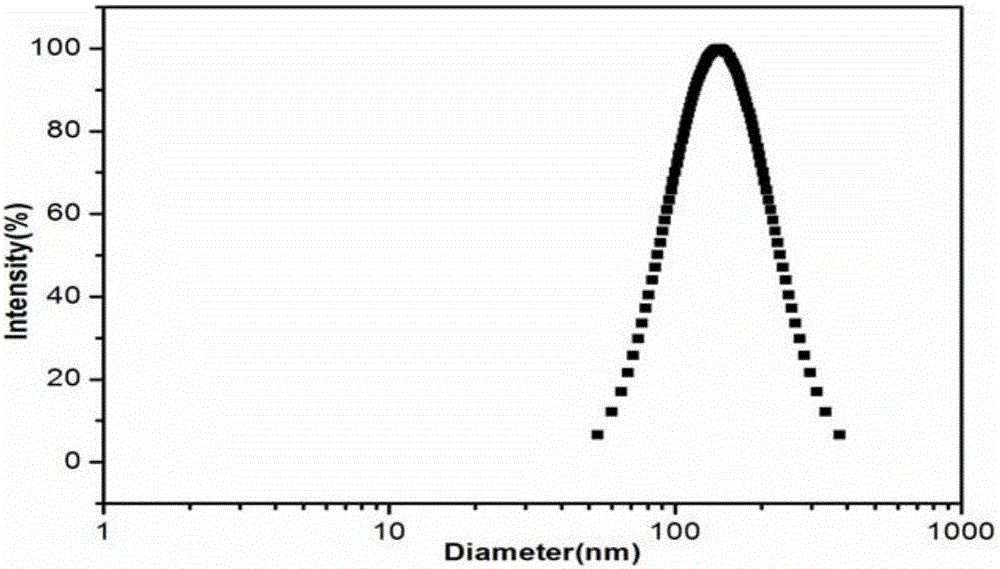

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap