A manufacturing method of aluminum alloy large-size flat ingot for ship hull

An aluminum alloy and large-size technology, which is applied in the field of manufacturing aluminum alloy large-size flat ingots, can solve the problems of poor mechanical strength, corrosion resistance, and low service life, so as to reduce cracking waste, reduce ship weight, and save energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

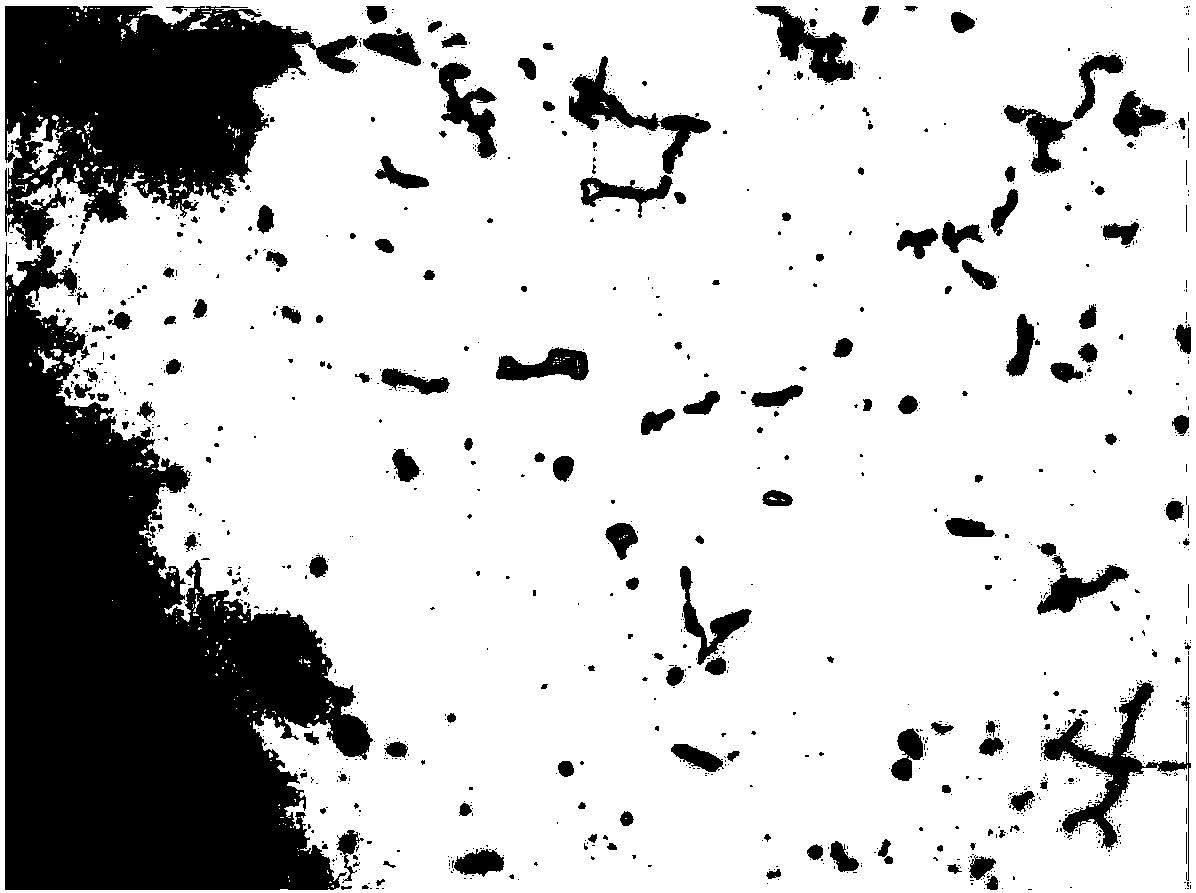

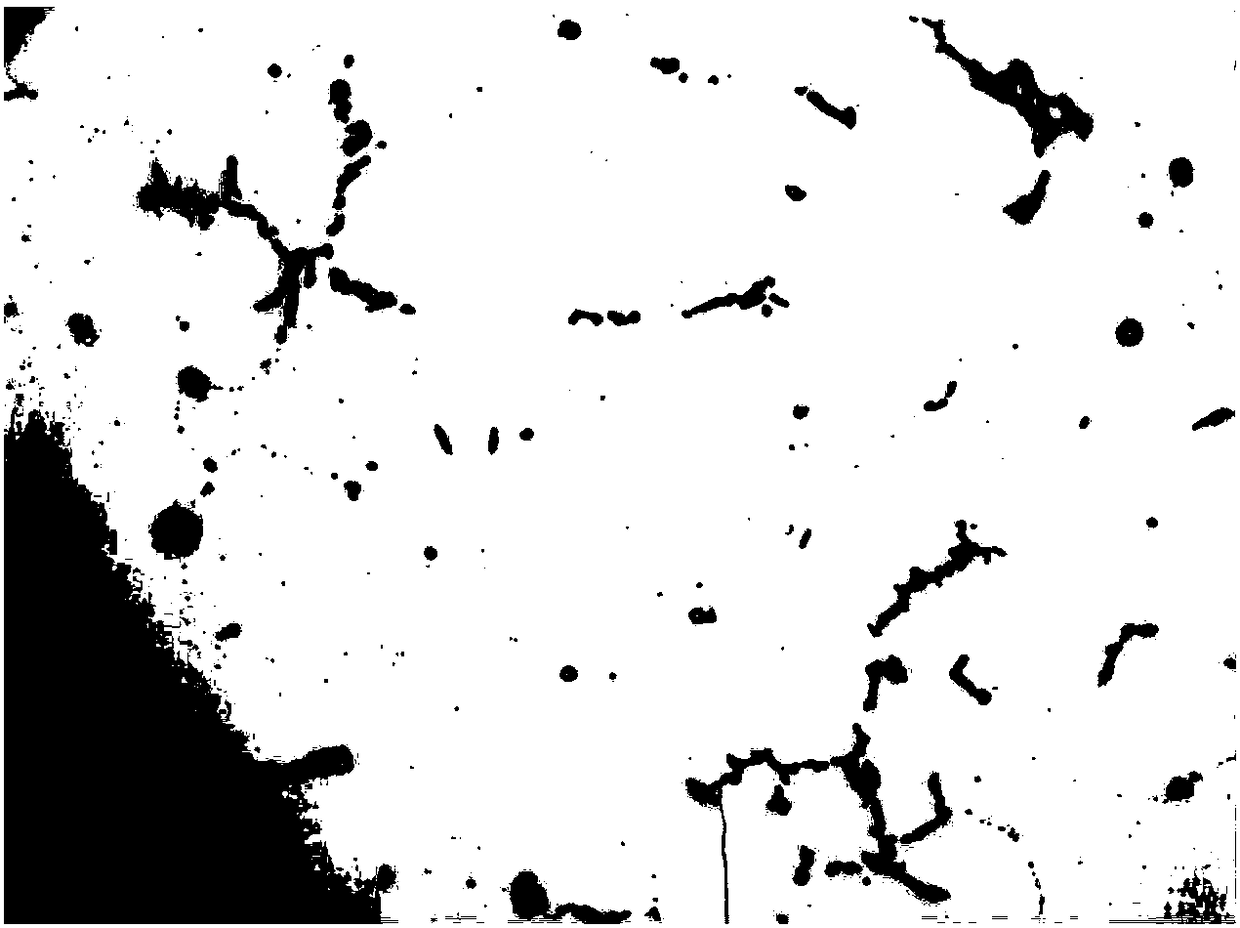

Image

Examples

specific Embodiment approach 1

[0021] Specific Embodiment 1: A large-scale slab cast ingot of an aluminum alloy for a ship hull described in this embodiment is composed of 0.7% to 1.1% Mn, 5.5% to 6.5% Mg, 0.03% to 0.15% Zr, and 0.10% by weight. % to 0.30% Er and the rest of Al are made as smelting raw materials; the impurity Si and Fe in the large-size slab ingot of aluminum alloy for ship hull are less than 0.4% by weight, the impurity Zn is less than 0.2% by weight, and the impurity The weight percentage of Cu, Ni and Cr is less than 0.1%.

specific Embodiment approach 2

[0022] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the aluminum alloy large-size slab ingot for ship hull is composed of 0.9% Mn, 6.2% Mg, 0.09% Zr, 0.22% Er and the balance by weight percentage Al is made as a smelting raw material. Other steps and parameters are the same as in the second embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: The manufacturing method of the aluminum alloy large-size slab ingot for the hull of a ship as described in the specific embodiment one is realized in the following steps:

[0024] 1. Weigh 0.7% to 1.1% of Mn, 5.5% to 6.5% of Mg, 0.03% to 0.15% of Zr, 0.10% to 0.30% of Er and the rest of Al in percentage by weight. Put into different containers, stand-by; The Mn of described 0.7%~1.1% is realized by weighing aluminum-manganese master alloy, and the Mg of described 5.5%~6.5% is realized by weighing metal magnesium, and the Mn of described 0.03% to 0.15% of Zr is achieved by weighing an aluminum-zirconium master alloy, the 0.10% to 0.30% of Er is achieved by weighing an aluminum-erbium master alloy, and the Al is achieved by weighing an aluminum ingot;

[0025] 2. Preparation of aluminum alloy melt: first add the weighed aluminum ingot into the resistance reverberatory furnace, then add aluminum-manganese master alloy and aluminum-zirconium mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com