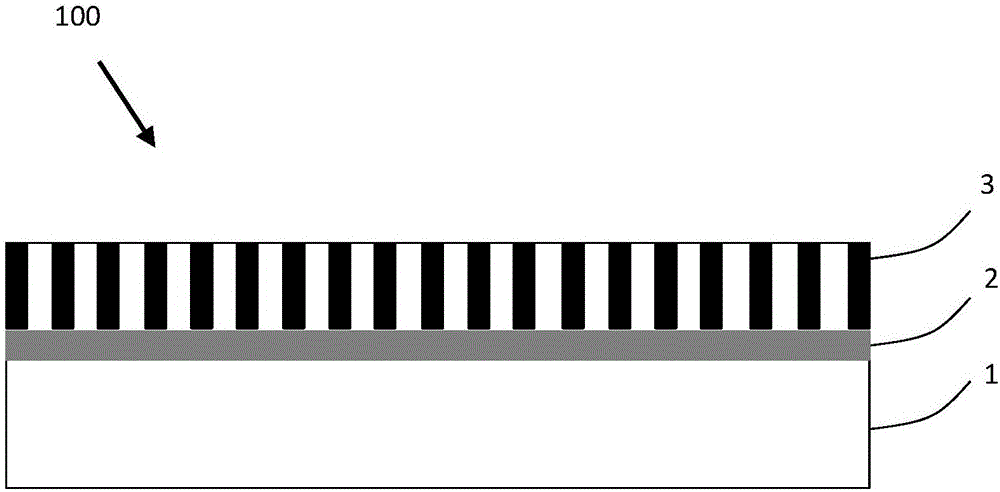

Preparation and surface modification methods of ferrous titanate/iron trioxide composite photoelectrode

A ferric oxide and surface modification technology, applied in the field of materials, can solve the problems of photoelectrode morphology change, harsh experimental conditions, complex preparation method of composite photoelectrode, etc., achieving easy control of experimental conditions, simple and controllable steps, The effect of high photoelectric catalytic water splitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

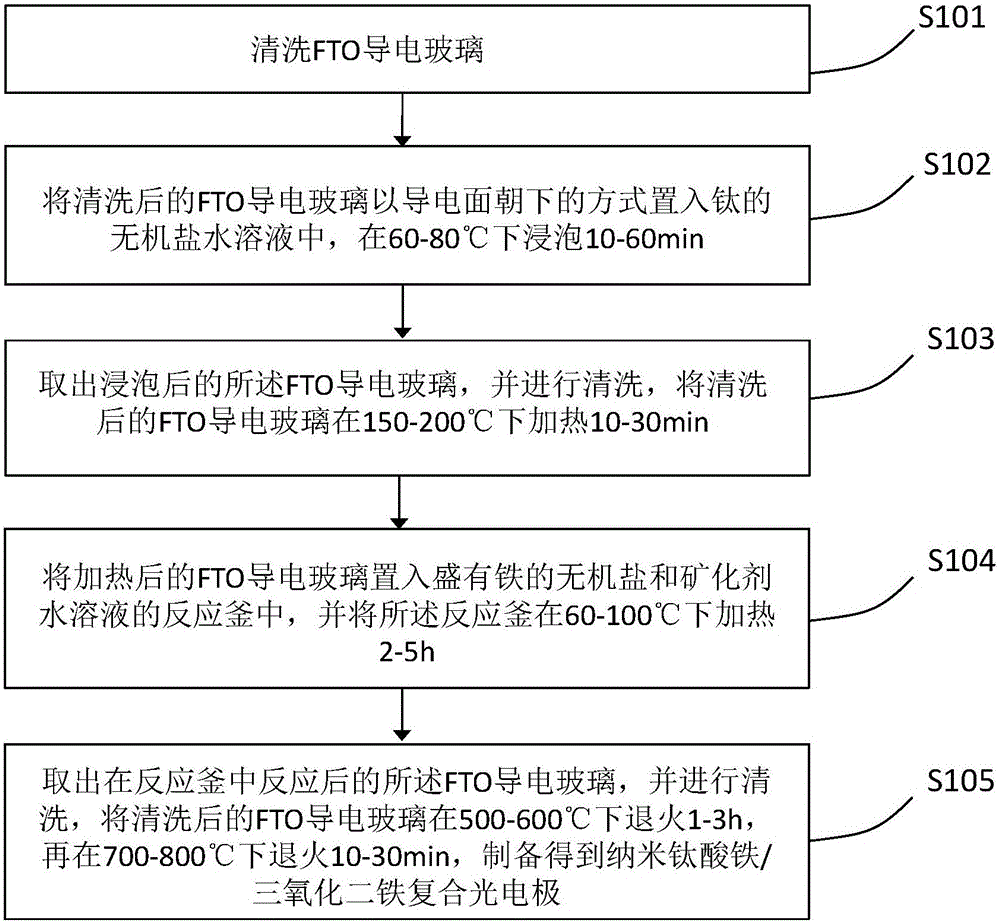

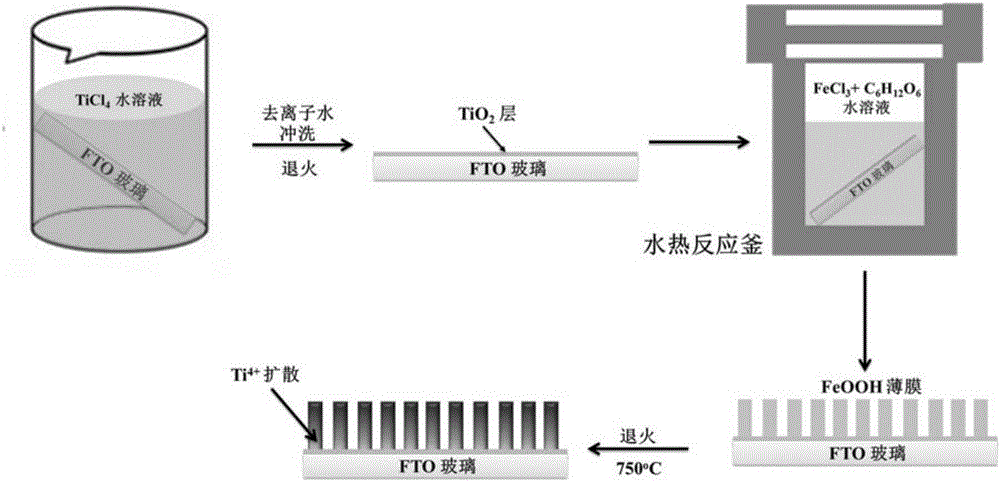

Method used

Image

Examples

Embodiment Construction

[0060] For the following defined terms, unless a different definition is given in the claims or elsewhere in this specification, these definitions shall apply. All numerical values, whether or not expressly indicated, are defined herein as modified by the term "about". The term "about" generally refers to a numerical range that one of ordinary skill in the art considers equivalent to the stated value to produce substantially the same property, function, result, etc. A numerical range indicated by a lower value and an upper value is defined to include all values included within that numerical range and all subranges included within that numerical range. The term "nanoscale" is defined as having at least one dimension below 100 nanometers. The term "micron-scale" is defined as having at least one dimension below 5 microns. All occurrences of "mM" are to be considered as abbreviations for "mmol / l". All occurrences of "M" are considered an abbreviation for "mol / l".

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com