Silicon carbide single crystal manufacturing device

A silicon carbide single crystal and manufacturing device technology, which is applied in the direction of single crystal growth, single crystal growth, semiconductor/solid-state device manufacturing, etc., can solve the problems of slowing down the growth rate, difficult to control the temperature of the crystal growth surface accurately, and prone to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

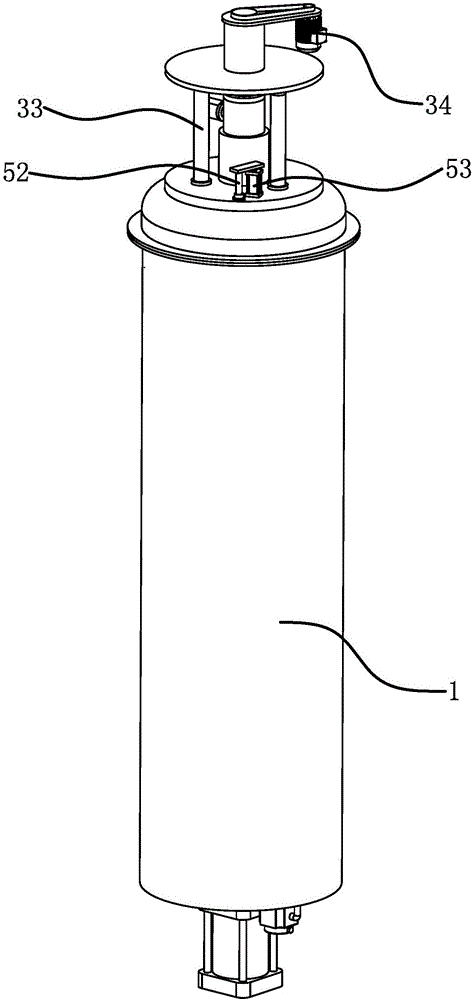

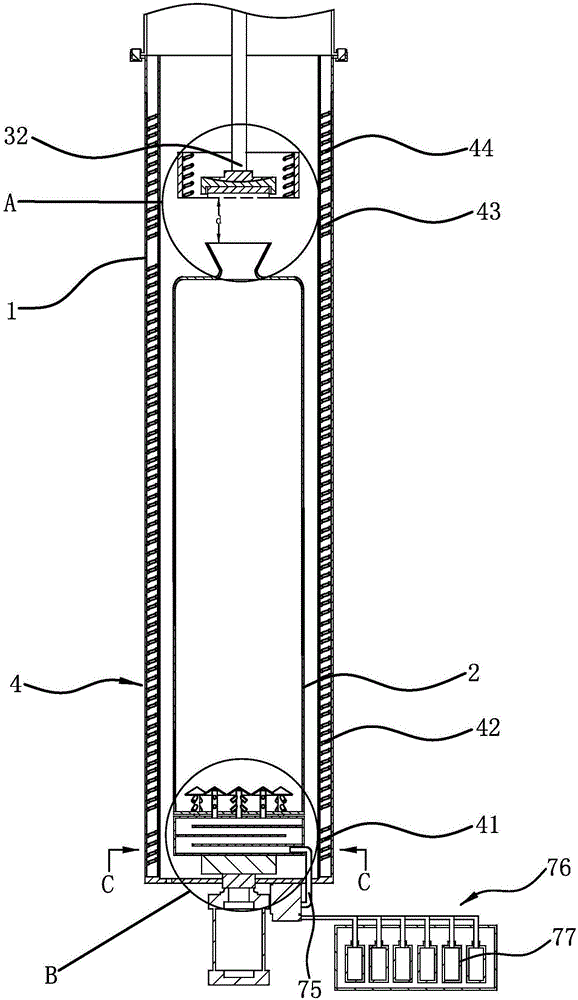

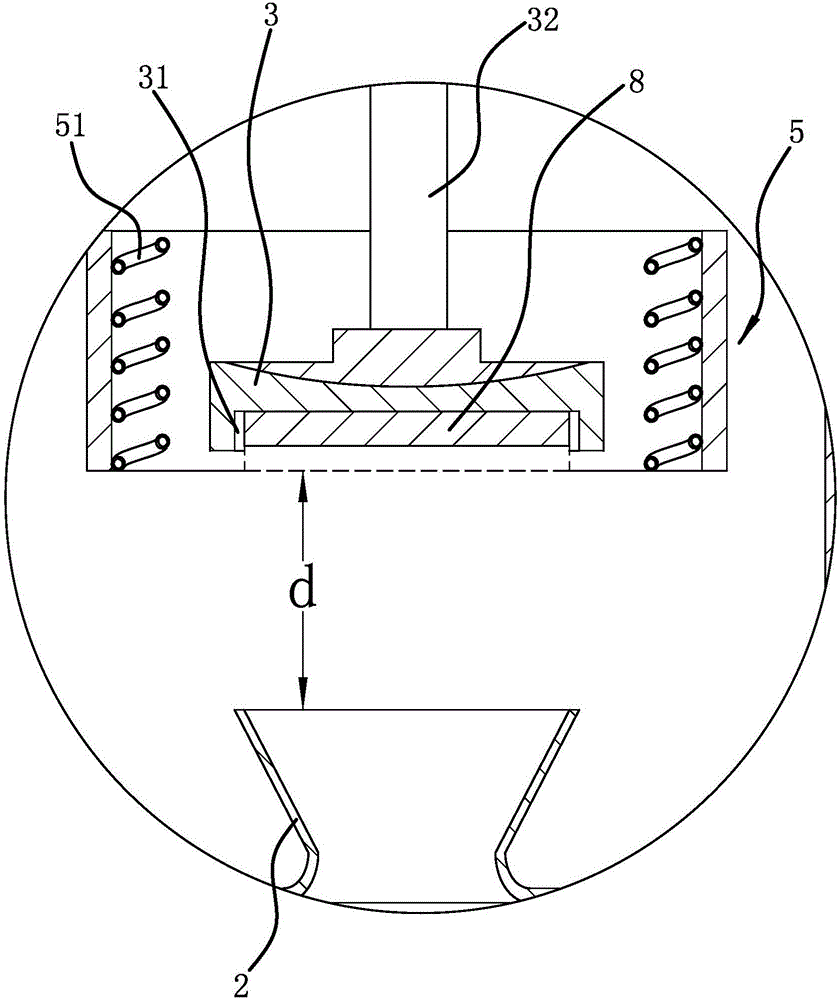

[0039] Such as figure 1 , figure 2 , image 3 As shown, a silicon carbide single crystal manufacturing device includes a furnace body 1 and a crucible 2 arranged in the furnace body 1, silicon carbide powder is placed in the crucible 2, and a seed crystal holder 3 is arranged on the upper part of the crucible 2, and the seed crystal is kept A seed crystal 8 is installed on the frame 3, and the seed crystal holder 3 can rotate and lift up and down, that is, the upper end of the furnace body 1 is rotatably connected with a lifting shaft 32. 3 is installed on the lower end of the lifting shaft 32, and the upper end of the lifting shaft 32 is respectively connected with a motor 34 that can drive the lifting shaft 32 to rotate and a cylinder one 33 that can drive the lifting shaft 32 up and down. In the furnace body 1, a furnace body heater 4 is also provided, and the furnace body heater 4 can heat the furnace body 1 to form an ambient temperature gradient in the furnace body 1,...

Embodiment 2

[0052] The structure of the silicon carbide single crystal manufacturing device is basically the same as that of Embodiment 1, the difference is that Figure 8 As shown, the upper end of the seed crystal holder 3 faces downward arc-shaped concave, then cooperates with the setting of the parameter controller, and heats the outside of the grown silicon carbide single crystal through the heating cooler 5, so that the temperature gradient of the crystallization surface is maintained. Increase or decrease within the range of 0.5°C / mm to 20°C / mm.

Embodiment 3

[0054] The structure of the silicon carbide single crystal manufacturing device is basically the same as that of Embodiment 1, the difference is that Figure 9 As shown, the upper end surface of the seed crystal holder 3 has a flat-bottomed concave cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com