An intelligent robot for building drainage pipes buried

An intelligent robot and building drainage technology, which is applied in the sewer system, building, waterway system, etc., can solve the problems of high labor intensity, capital loss, and single function, so as to improve the sealing and firmness, and increase the uniform secondary The effect of mixing and mechanical intelligence with high degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

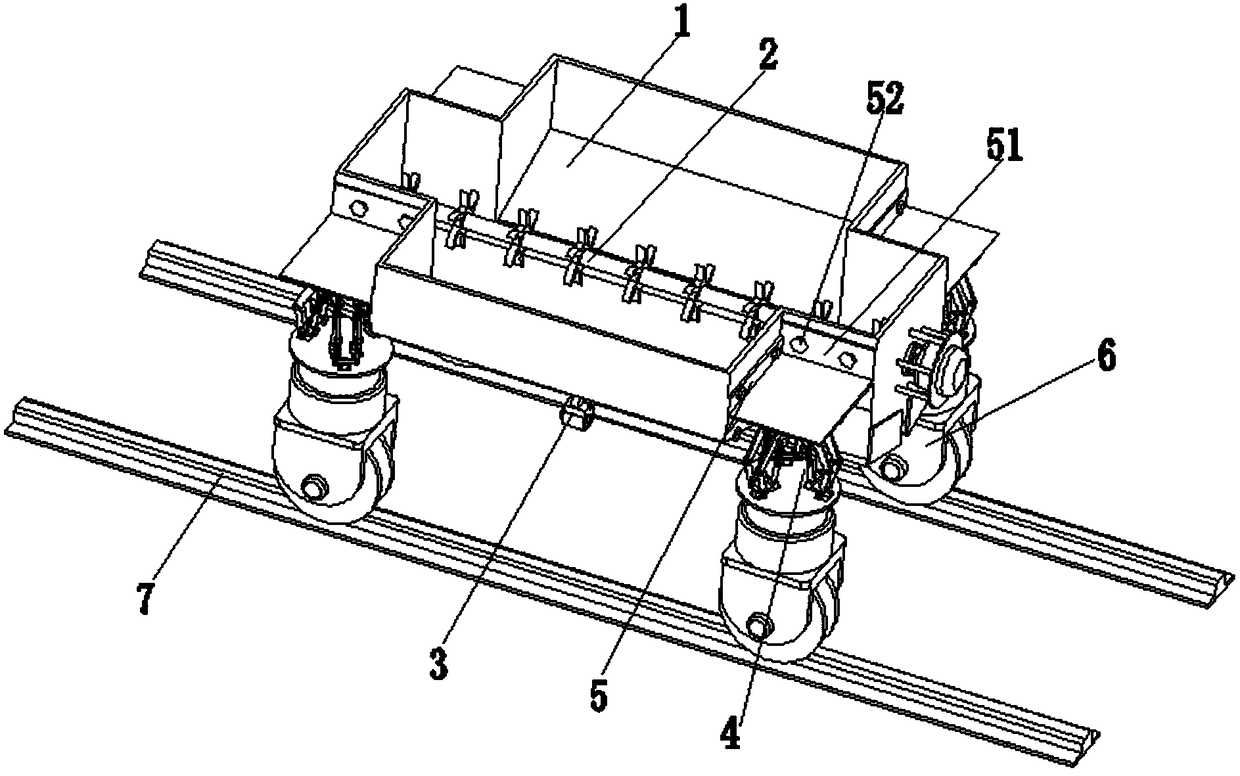

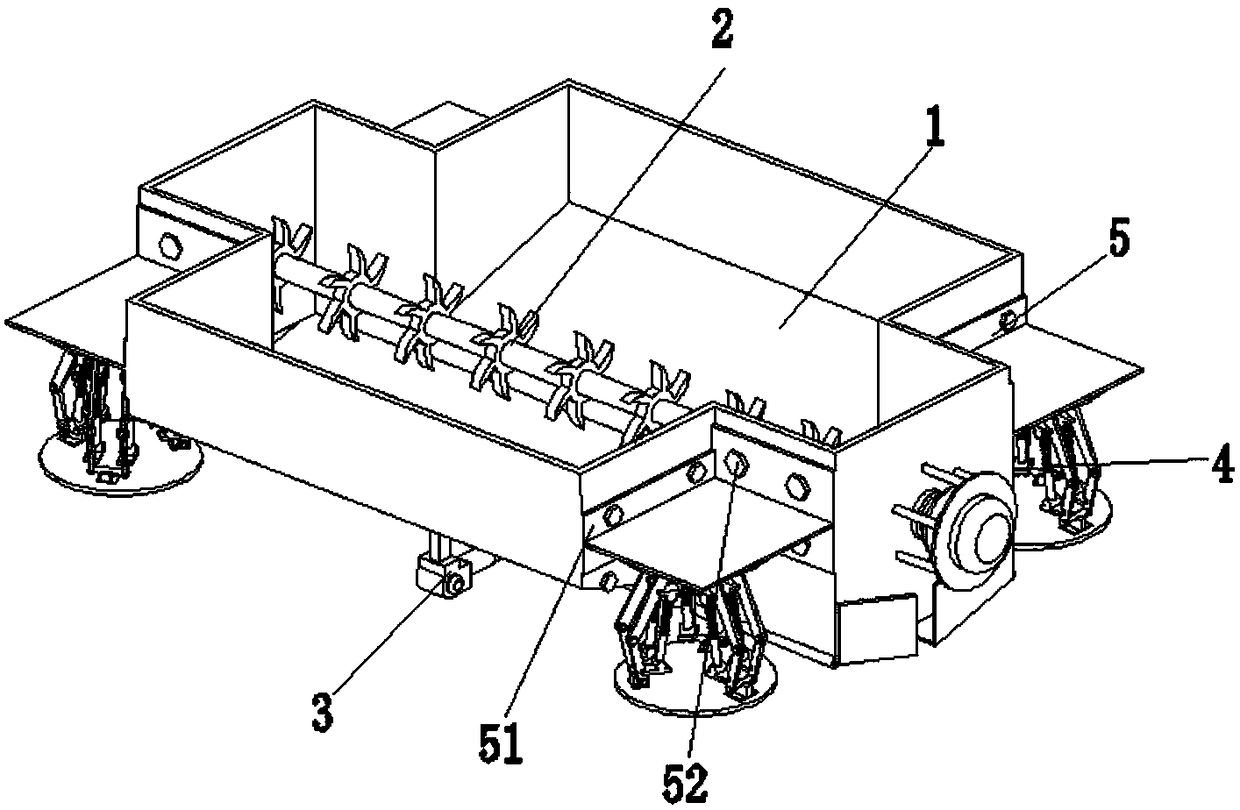

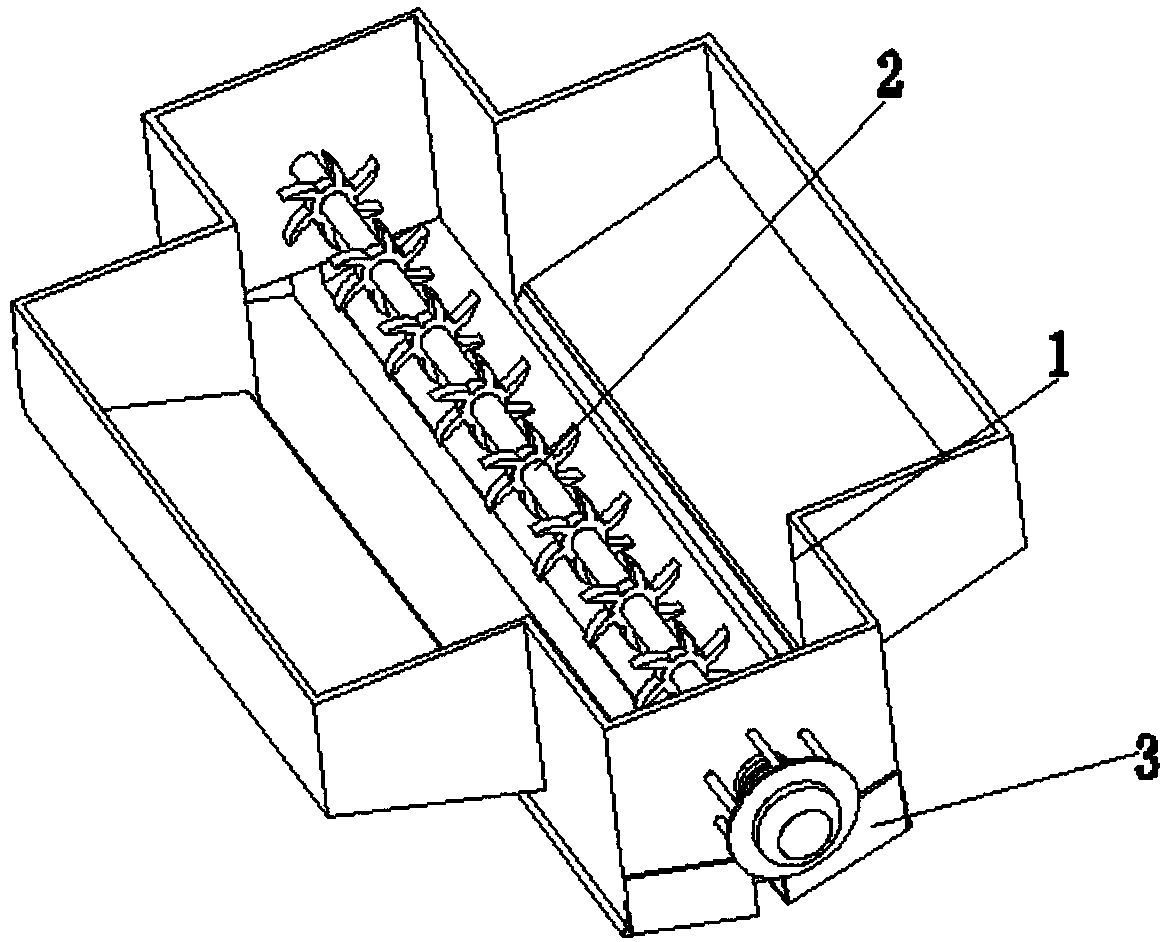

[0033] Such as Figure 1 to Figure 9 Shown, a kind of building drainage pipeline burys intelligent robot, comprises storage tank 1, stirring device 2, adjustable discharge device 3, delta parallel vibration table 4, fixing device 5, walking device 6 and track 7; The trough 1 has a cross-shaped shell structure, and the upper end of the trough 1 is open, and the left and right sides of the lower end of the trough 1 are provided with inclined bottom plates. A square leak is provided at the middle of the lower end of the tank 1; the stirring device 2 is located inside the storage tank 1, and the number of adjustable discharge devices 3 is two, and the adjustable discharge device 3 is located at the middle of the lower end of the storage tank 1. dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com