Self-hole-forming and self-tapping shearing force connection piece and construction method thereof

A connecting piece and self-opening technology, applied in the direction of construction, building structure, etc., can solve the problems of reducing the bearing capacity of composite beams, complicated construction, weakening of the effective section of wooden beams, etc., and achieves reliable mechanical properties, convenient construction, and good weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

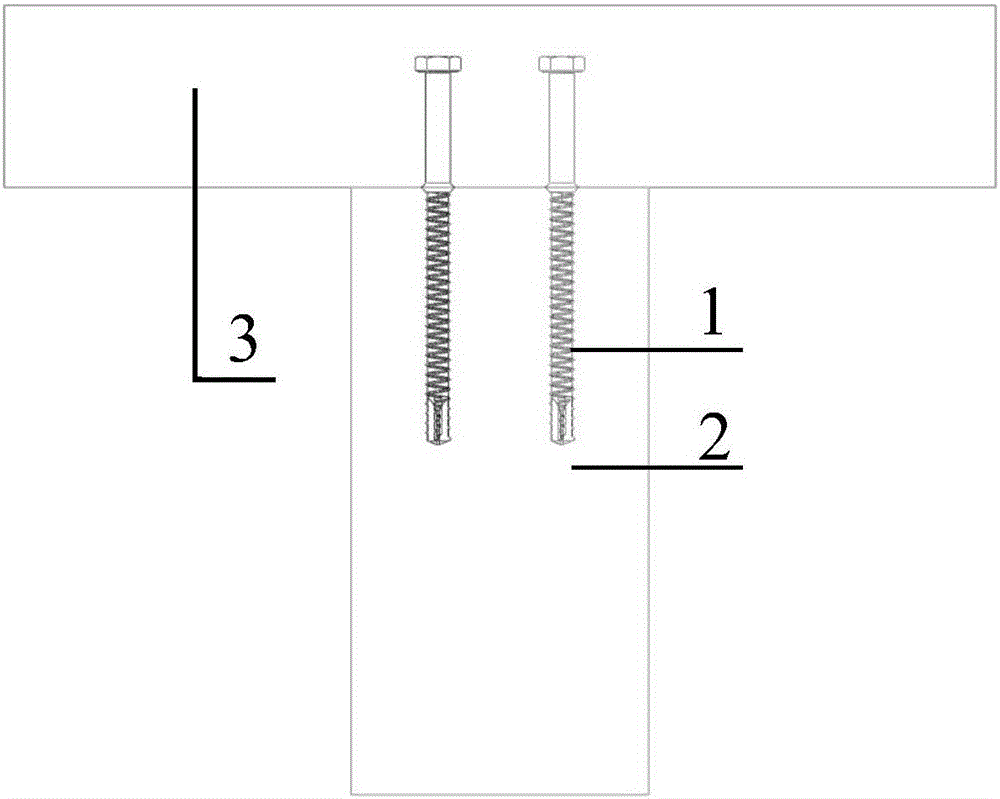

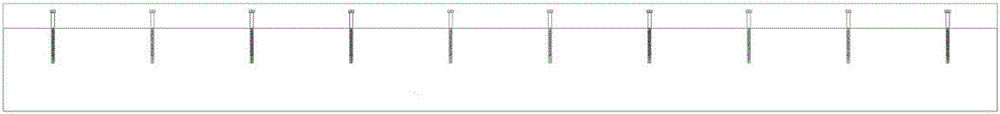

[0059] like Figure 1-8 As shown, a self-tapping self-tapping shear connector, the self-tapping self-tapping shear connector 1 combines a glued wood beam 2 and a lightweight aggregate concrete wing 3;

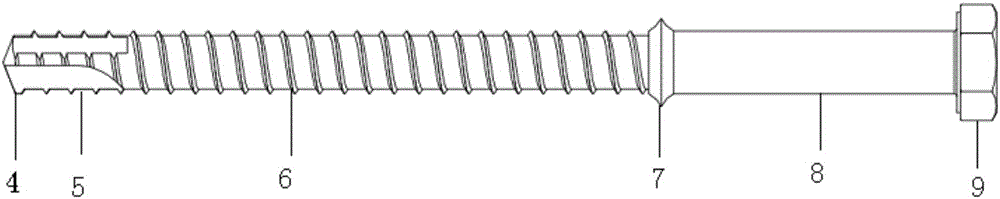

[0060] The self-drilling self-tapping shear connector 1 includes a drill bit 4, a chip storage tank 5, a screw thread 6, a limit joint 7, a nail rod 8 and a hexagonal head 9;

[0061] The nail rod 8 is divided into a smooth section and a threaded section. The smooth section is poured into the bottom surface of the lightweight aggregate concrete wing plate 3, and the threaded section is nailed into the top surface of the glued wood beam 2; The limit joint 7 that controls the depth of the shear connector embedded in the glued wood beam 2 at any embedding angle;

[0062] The threaded section is provided with a thread 6 that converts the input tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com