Intelligent prestress tensioning method

An intelligent tensioning and prestressing technology, applied in the construction, building structure, construction material processing and other directions, can solve the problems of short anchoring time, fast unloading speed, large control error, etc., and achieve high tensioning quality and detailed data. , good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

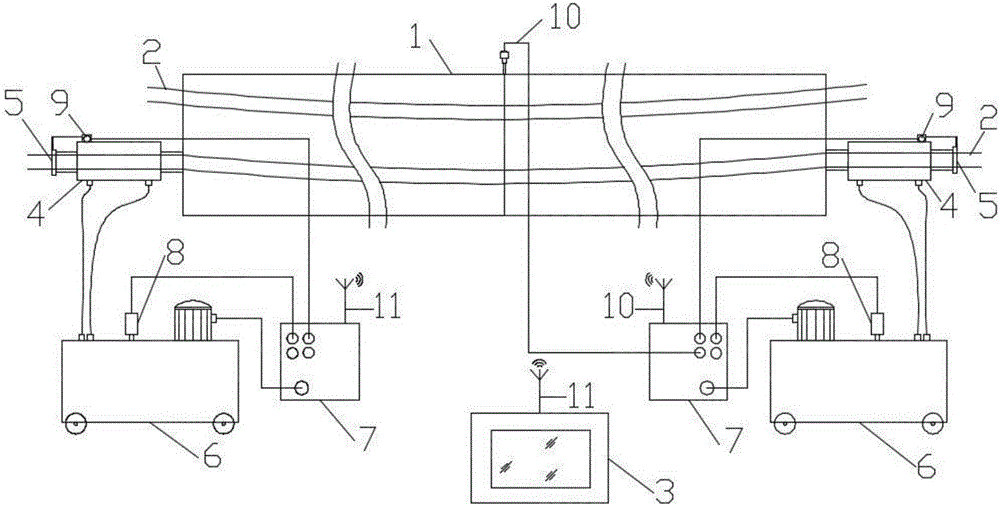

[0014] Such as figure 1 As shown, a prestressed intelligent stretching method includes component 1, prestressed tendon 2 and program-controlled host 3; prestressed automatic tensioning equipment and its computer control system are used to replace manual operation control for tensioning, prestressed intelligent tensioning The system is mainly composed of a program-controlled host, a jack 4, an oil pump 6, a front-end controller 7, an oil pressure sensor 8, a pull-wire displacement sensor 9, an arch displacement measurement sensor 10, and a wireless transmission network 11. The length error is used as a proofreading index. The system collects the working pressure of each tensioning equipment and the elongation value of the steel strand through sensing technology, and transmits the data to the system host in real time for analysis and judgment. At the same time, the tensioning equipment receives system instructions to realize The tensioning force and loading speed are precisely c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com