Automatic reversing type bidirectional stepping piston

An automatic reversing and stepping technology, which is applied in the direction of fluid pressure actuators, etc., can solve the problems of high processing requirements, large volume, complex structure of gear mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

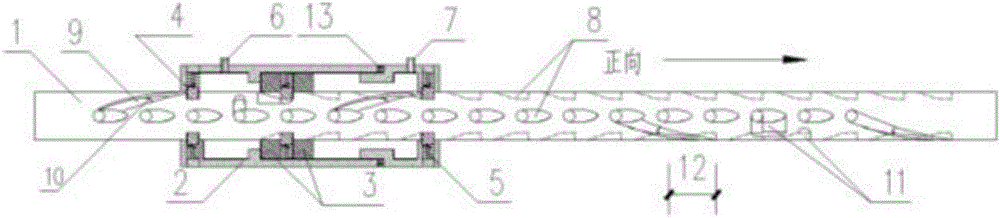

[0015] Such as figure 1 As shown: the automatic reversing bidirectional stepping piston is mainly composed of a stepping piston cylinder 2, an annular piston 3 and a stepping piston shaft 1; the annular piston 3 is sleeved inside the stepping piston cylinder 2 and in the middle of the stepping piston 2 cylinder Moving, the stepping piston shaft 1 runs through the stepping piston cylinder 2 and the annular piston 3 and moves in the stepping piston cylinder 2 and the annular piston 3; the stepping piston cylinder 2 is provided with a return air port 6 and a process air port 7, and the stepping piston Both the cylinder 2 and the annular piston 3 are provided with a backstop pin 4, and a spring 5 is arranged behind the backstop pin 4; The retreating chute 8 is arranged in reverse, the arc-shaped chute 9 is arranged at both ends of the distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com