Laser vibration measurement calibration big trigger delay accumulation calibration method

A technology of trigger delay and laser vibration measurement, which is applied in measuring devices, using wave/particle radiation, measuring ultrasonic/sonic/infrasonic waves, etc. It can solve the problems that the delay of the delayer cannot be set arbitrarily, and the accuracy is not easy to be high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

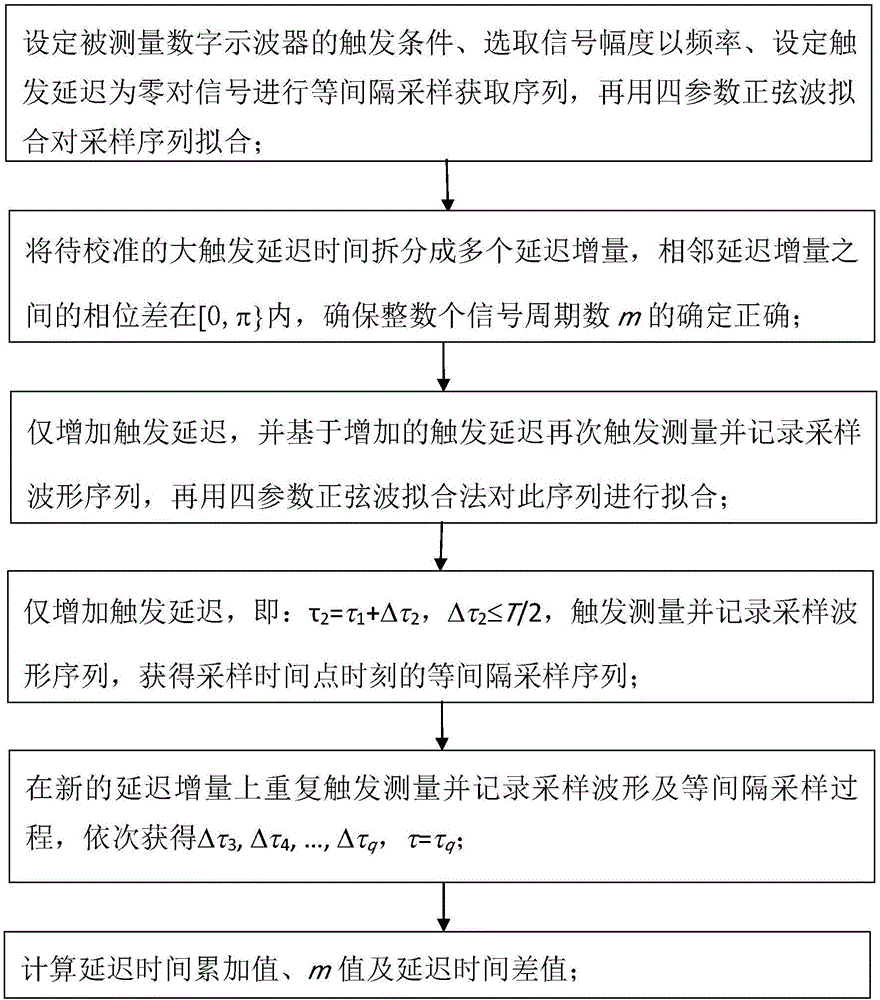

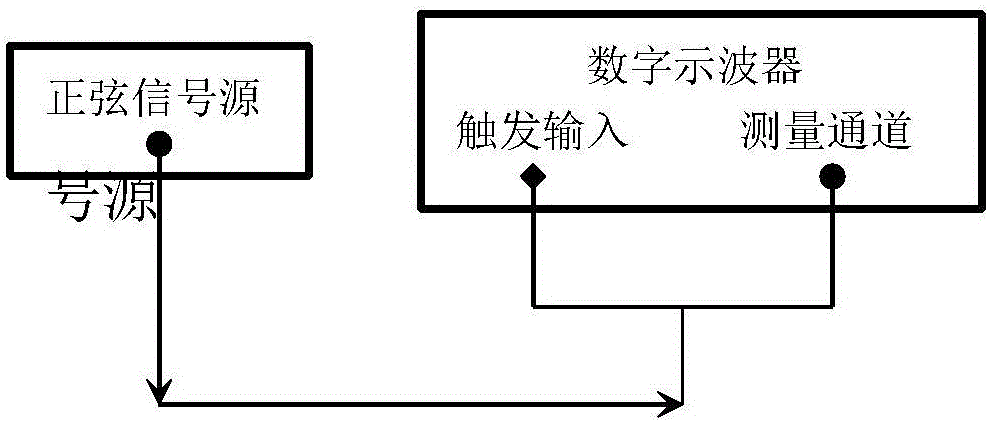

[0095] This embodiment describes the implementation process of the method proposed in the present invention, a laser vibrometer calibration with a large trigger delay cumulative calibration method, which is specifically realized by measuring the large trigger delay with a digital oscilloscope. The flow chart is as follows figure 1 As shown, the schematic diagram of the principle is shown in figure 2 shown.

[0096] From figure 1 It can be seen that the implementation process of the cumulative calibration method with a large trigger delay in the proposed method of the present invention is a kind of laser vibration measurement calibration, including:

[0097] Step 1: Set the trigger condition of the digital oscilloscope to be measured, select the signal amplitude and frequency, set the trigger delay to zero, sample the signal at equal intervals to obtain the sequence, and then use the four-parameter sine wave fitting to fit the sampling sequence;

[0098] Step 2: Split the la...

Embodiment 2

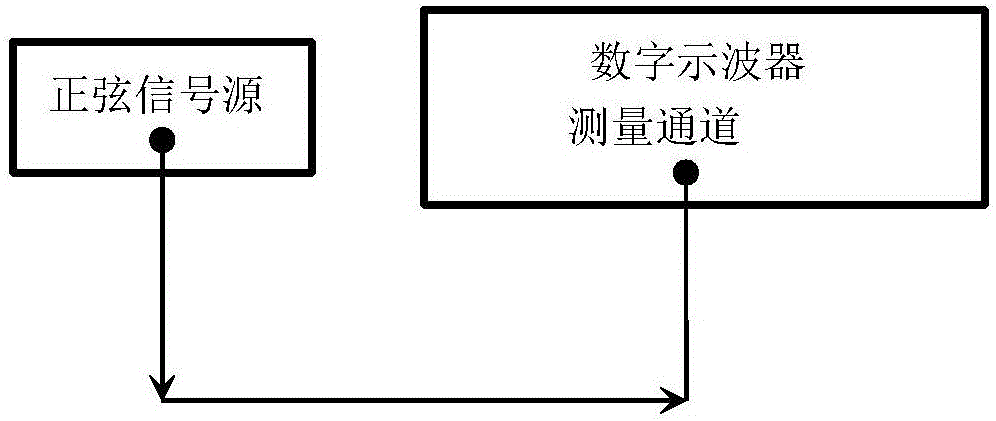

[0119] This embodiment illustrates another implementation process of the method proposed in the present invention, an accumulation calibration method with a large trigger delay for laser vibrometer calibration, that is, it does not need to be stimulated by a signal source, but is directly triggered by a measurement channel. Its schematic diagram is as follows image 3 shown.

[0120] image 3 In the above, the sinusoidal signal source applies sinusoidal excitation to the digital oscilloscope under test, and at the same time provides it with a sinusoidal trigger signal. The specific process is the same as that of Embodiment 1, except that the trigger channel is the input channel itself, and there is no need to introduce it from a special trigger terminal.

[0121] It can be seen from the above embodiments 1 and 2 that the method of the present invention does not need to use a fixed delayer or a delay circuit, and can perform metering and calibration for trigger delay time dif...

Embodiment 3

[0123] This embodiment illustrates a simplified implementation process of a laser vibrometer calibration with a large trigger delay cumulative calibration method proposed in the present invention, that is: only based on the measurements under the two conditions of maximum trigger delay and zero delay, Determine trigger delay results.

[0124] During the specific implementation of this embodiment, when it is ensured that the maximum allowable error limit of the large trigger delay τ of the digital oscilloscope is not greater than T / 2, when the sine wave with a period of T is used for the maximum delay calibration traceability, the rounding operation m=int[τ can be directly used / T] Confirm and judge the number m of sine wave cycles contained in it, and use the time difference corresponding to the phase difference between the two sine sample sequences when the delay time is 0 and the delay time is τ under the same measurement conditions to calculate less than one wave cycle Part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com