Junction temperature calibration method based on mathematical filtering algorithm

A technology of filtering algorithm and calibration method, which can be applied to measurement devices, instruments, measuring electricity and other directions, which can solve the problems of device damage and theoretical errors that cannot accurately measure the junction temperature value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In the following, in conjunction with the accompanying drawings, a specific implementation of a certain type of IGBT semiconductor device as an example but not limited to this example will be used to describe the present invention in more detail.

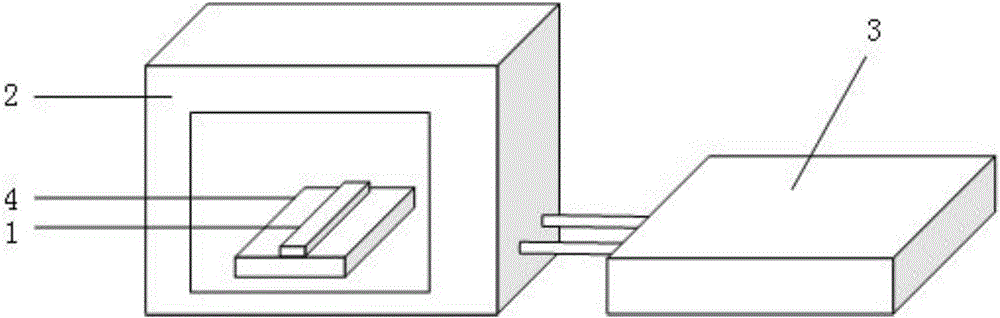

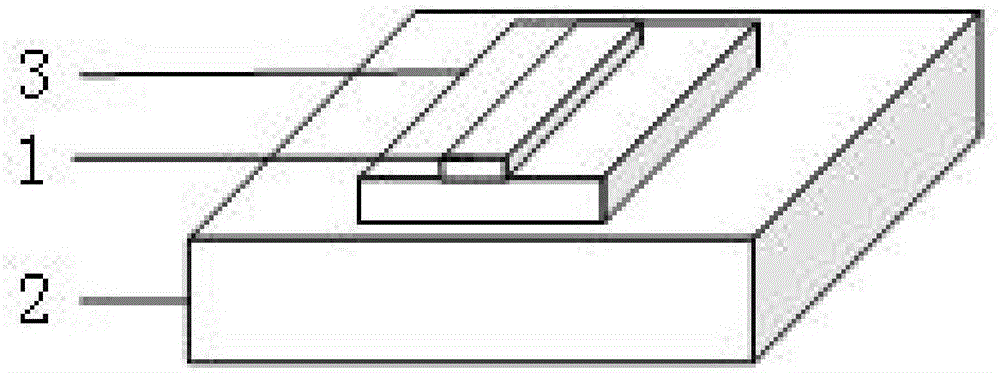

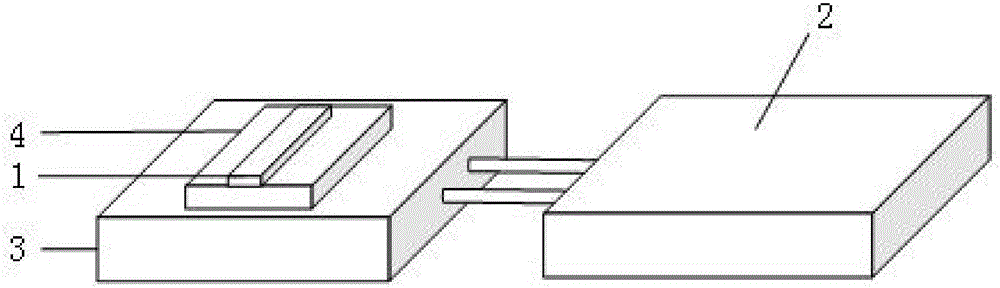

[0070] The test device involved in the present invention is such as figure 1 and figure 2 Shown.

[0071] Step one, connect the semiconductor device (1) with the semiconductor temperature calibration curve measuring device (3), put it in the thermostat (2), measure and establish the temperature-current-voltage temperature calibration surface of the semiconductor device through the electrical method, in the form image 3 Shown.

[0072] Step 2: The semiconductor device (1) and the semiconductor thermal resistance measuring instrument (4) measure the thermal resistance composition of the semiconductor device, and establish an RC thermal resistance model. In this example, the IGBT model of this type is as Figure 4 As shown, the estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com