High-strength steel material having excellent fatigue characteristics

A technology with fatigue characteristics and high strength, applied in the furnace type, furnace, heat treatment furnace, etc., can solve the problems of high alloy cost and high Cr addition, and achieve the effect of improving fatigue characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

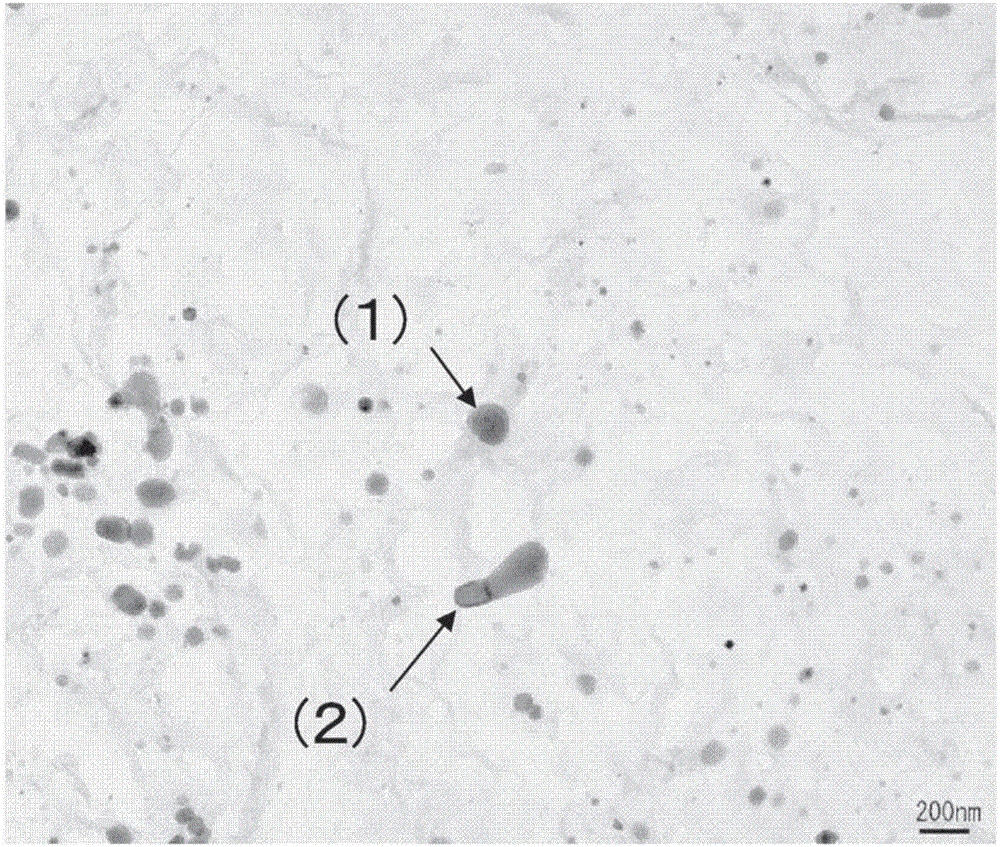

[0102] Hereinafter, examples are given to illustrate the present invention more specifically, but the present invention is of course not limited by the following examples, and it is of course possible to appropriately modify and implement them within the range that can meet the gist of the foregoing and the following, and these are all included in the present invention. within the technical range. That is, in the present invention, regardless of the processing sequence of quenching and tempering and coiling in the manufacturing process, excellent fatigue characteristics can be exhibited by controlling the number density of Cr-containing carbon-nitrides specified in the present invention. Therefore, in this example, as an example of the steel material of the present invention, a steel wire for spring was evaluated as an object, but a spring obtained by subjecting the spring to the spring, and the processing procedure of the quenching and tempering and the coiling of the spring w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| relative density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com