Apparatus and method for dynamically adjusting electric arc furnace

A kind of electric arc furnace, dynamic ground technology, applied in electric heating devices, reactive power adjustment/elimination/compensation, electrical components, etc., can solve the problem of not making optimal use of electric drive components, achieve effective arc stabilization, and improve power factor , to avoid the effect of arc interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

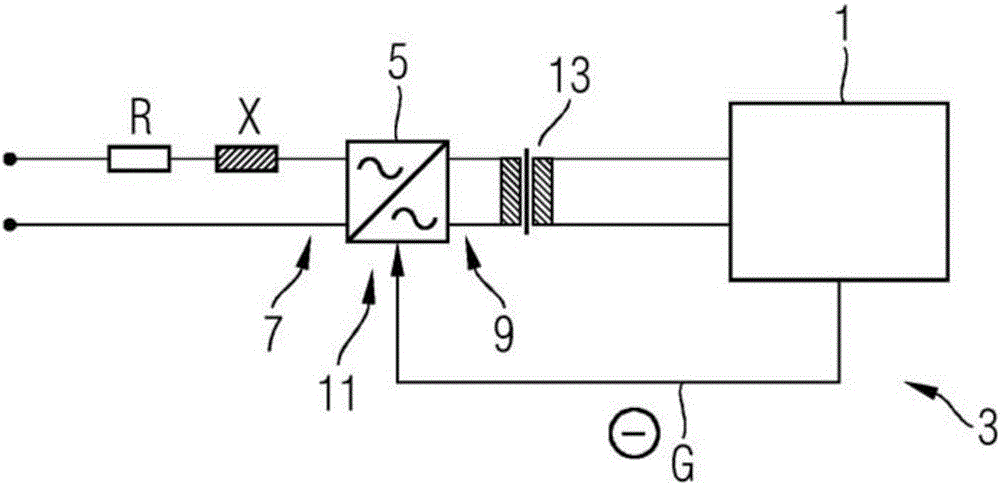

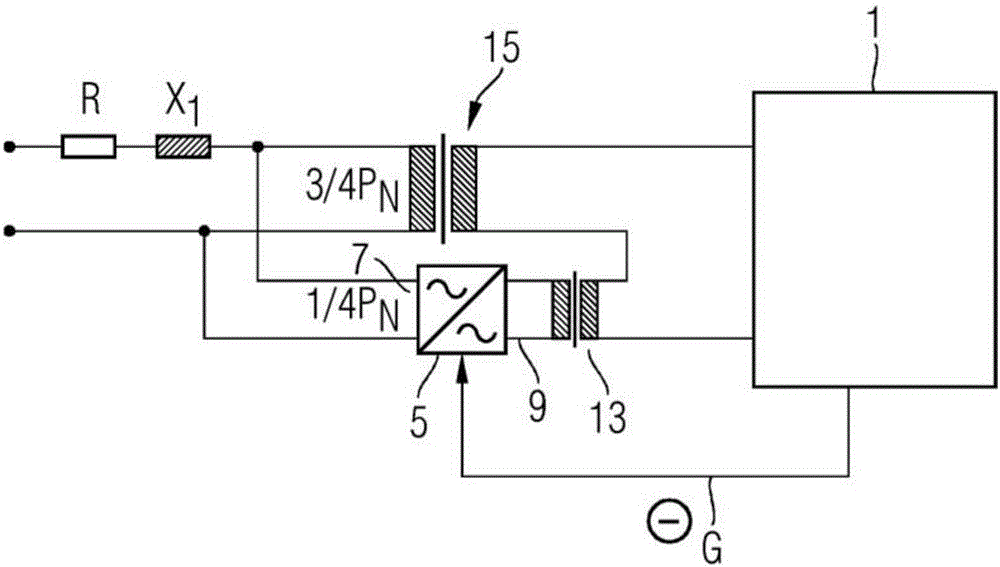

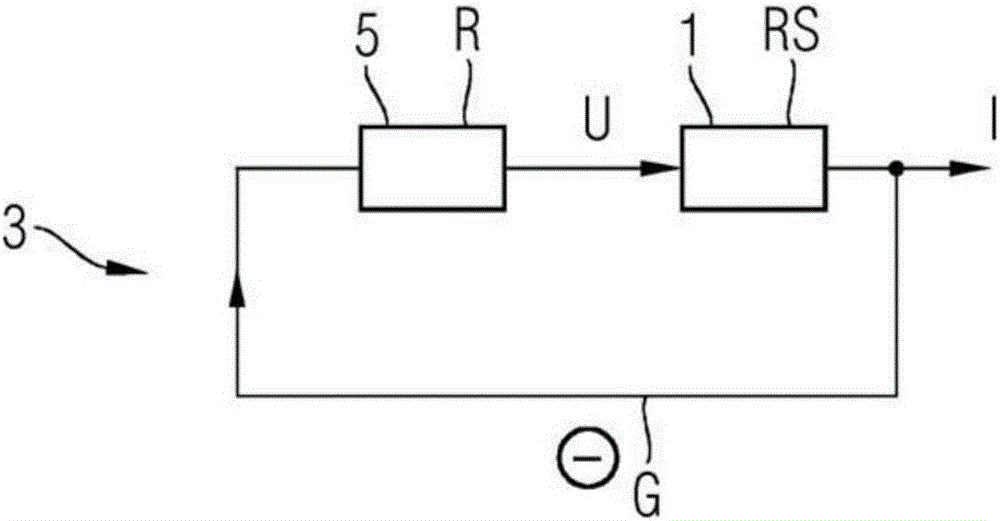

[0039] figure 1 A first embodiment of the device according to the invention is shown. According to this arrangement, the arc generated in the arc furnace 1 can be adjusted more dynamically and more flexibly than in the prior art. The corresponding arc is fed with the required energy in a phase-synchronous manner via the converter 5 in series with the first transformer 13 , which may be an already pre-installed furnace transformer, whereby the arc is not extinguished. Also avoid flickering. The device according to the invention also makes it possible to avoid overvoltages. All grid impedances including the converter transformer are aggregated into impedances R and X shown. figure 1A single-phase equivalent circuit diagram of the arc 1 is shown, in which the entire power, ie 100%, is fed via the converter 5 . This gives complete control over the arc furnace 1 , including the operating frequency and stepless voltage regulation from 0 to 100%. When the electric arc furnace 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com