Methods and compositions for forming solder bumps on a substrate with radiation curable or thermal curable solder flux

A technology of radiation curing and flux, applied in the direction of welding/cutting media/materials, assembling printed circuits with electrical components, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

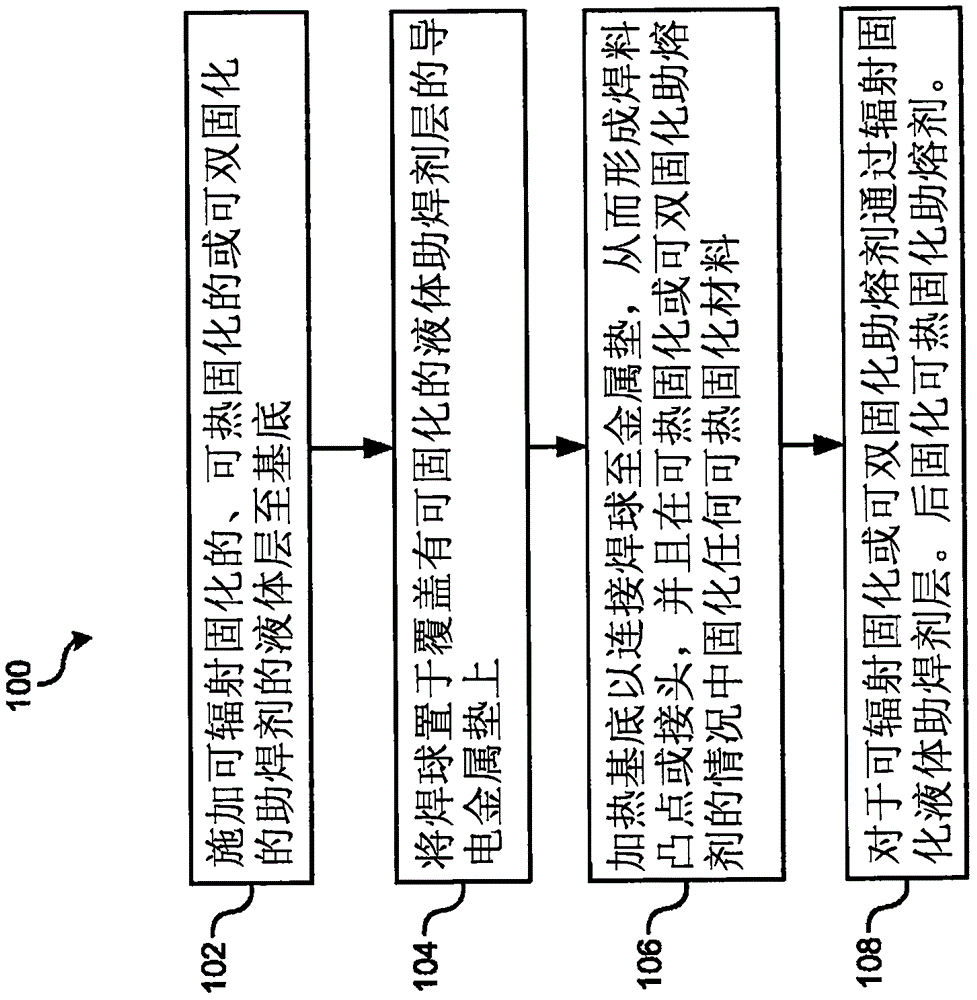

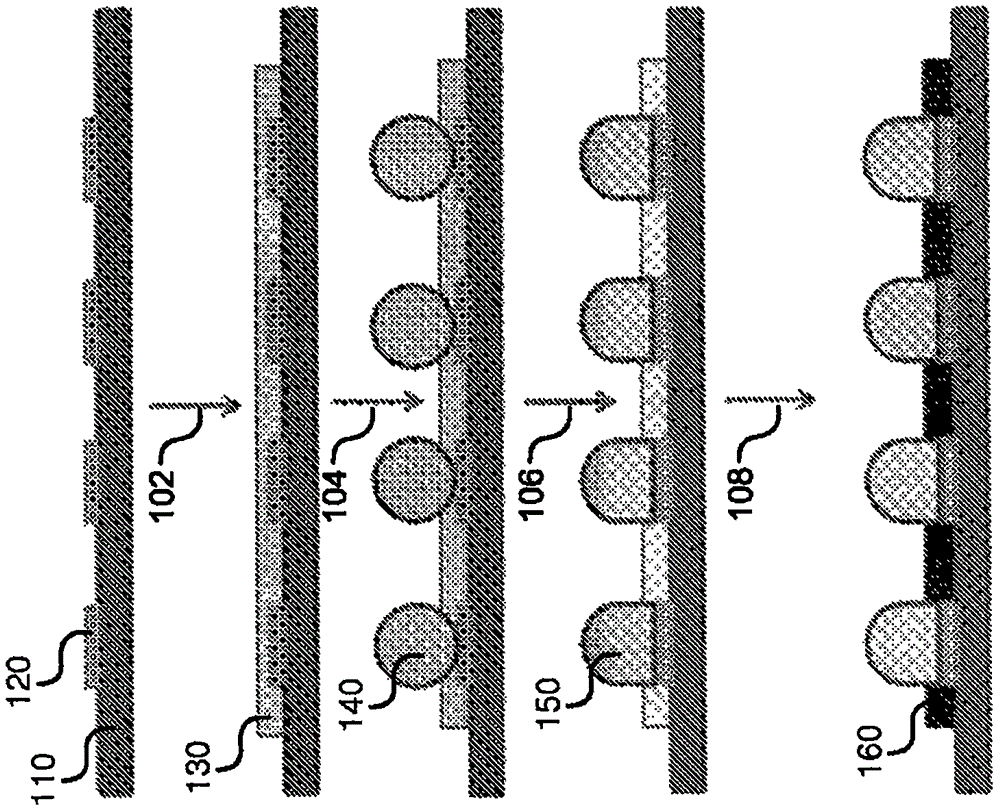

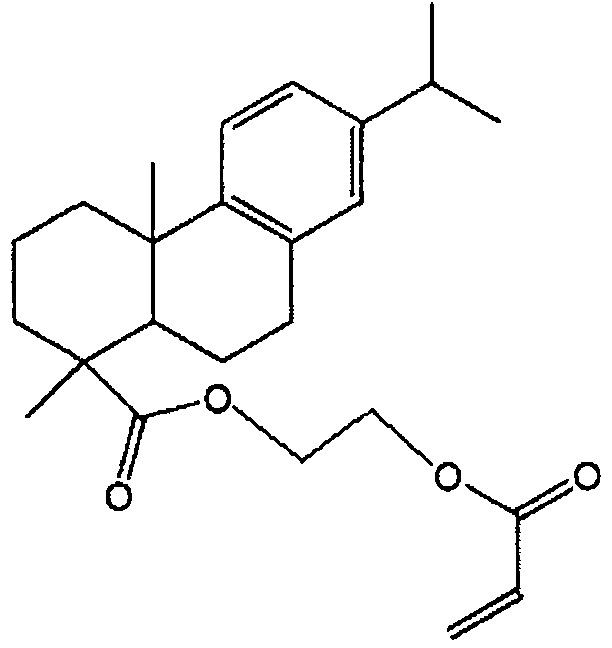

[0017] The methods and compositions disclosed herein relate to radiation curable (eg, by UV, visible light, or electron beam UV), thermally curable, or dual-curable flux compositions, and methods of processing such compositions. The flux composition can be used to form solder joints or solder bumps, and it can be exposed to heat, exposed to radiation (e.g., UV light, visible light, or electron beam), or exposed to two Those who solidify.

[0018] The cured flux can be used to strengthen solder bumps or joints, or in the case of semiconductor components to protect substrates such as printed circuit boards, electronics or silicon (or other semiconductor materials). Thus, by providing flux in combination with radiation curable, heat curable, or dual curable materials to form solder bumps and simultaneously form around the solder bumps as a support coating in semiconductor components and electronic devices The protective film of the embodiment can reduce processing steps. Thus, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com