A breast pad without a gap in the water-absorbing layer and its production method

A production method and technology of breast pads, applied in the field of breast pads, can solve the problems of water absorption layer volume loss, increase the frequency of changing breast pads for users, use cost, and reduce water absorption, so as to increase water absorption, avoid edge leakage, The effect of reducing frequency and usage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The breast pad of this embodiment includes: a water-conducting layer 1 (generally non-woven fabric, spunlace non-woven fabric, pure cotton cloth and other water-conducting materials), a water-absorbing body 2 and a waterproof layer 3 (generally PE film or other non-water-permeable membrane material); the breast pad is folded inward along the center line, so that the water-conducting layer 1 forms adjacent stacks, and the laminated water-conducting layers 1 are connected along a line, so that the breast pad unfolds A substantially conical cavity is formed.

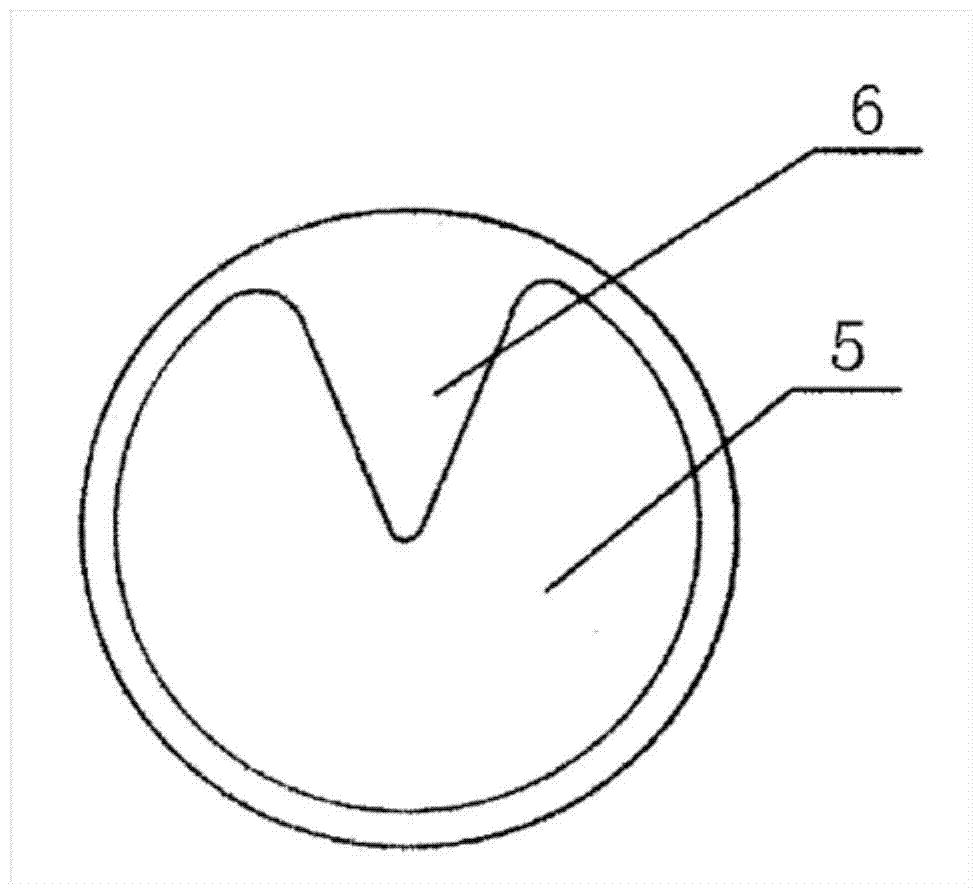

[0051] The water-conducting layer 1 of the laminate is connected along the line (such as Figure 5 with 6 ).

[0052] Such as Figure 9 , the water absorbent body 2 includes a laminated upper absorbent layer 2-2 and a water absorbent core 2-1, and the upper absorbent layer 2-2 and the water absorbent core 2-1 are wrapped by toilet paper 2-3; the upper absorbent layer 2-2 is fluff pulp, and the water-absorbing cor...

Embodiment 2

[0060] On the basis of Embodiment 1, there are the following modifications in this embodiment:

[0061] The laminated water-conducting layers 1 are connected along two lines, so that when the breast pad is unfolded, a substantially tapered cavity is formed.

[0062] The laminated water-conducting layer 1 is along the two lines (such as Figure 7 with 8 ) connected.

[0063] The production method of above-mentioned breast pad, comprises:

[0064] A. Fold the water-guiding layer 1 continuously distributed in a straight line in half along the centerline of the length direction, one side of the water-guiding layer 1 folded in half is the closed side 1-1, and the other side is the open side 1-2;

[0065] B. Forming along the closed side 1-1 of the water-conducting layer 1 by means of glue, heat-synthesizing, or ultrasonic welding: a plurality of fold lines distributed alternately for connecting the laminated water-conducting layers 1 to each other or line-segment-shaped connect...

Embodiment 3

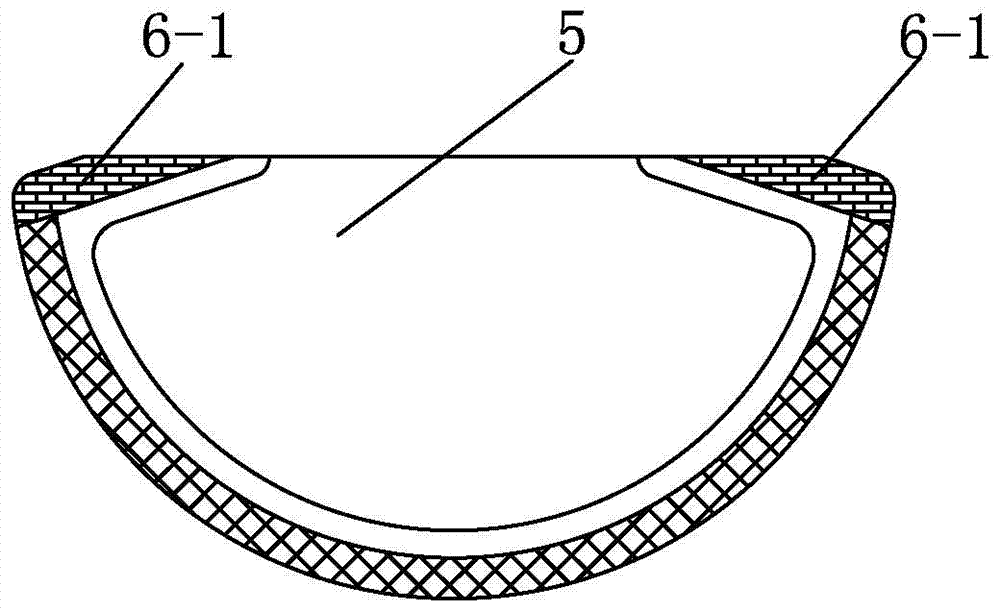

[0070] A breast pad 5, comprising: a water-conducting layer, a water-absorbing body, and a waterproof layer stacked in sequence; the breast pad is folded inward along the center line and shaped so that when the breast pad is unfolded, it forms a substantially conical or hemispherical cavity.

[0071] The shaping refers to connecting the laminated layers of 4 at any end corner of the water-absorbing body in the double-folded breast pad, and the connection method is continuous or intermittent, specifically connected by glue or suture, such as Figure 4 Or 5. Or connect the laminated water-absorbing body 2 at any end corner by nailing (using plastic nails).

[0072] The production method of described breast pad comprises:

[0073] a. Place the water-absorbing body 2 on a water-guiding layer 1, and fold it in half along the center line of the water-absorbing body 2, and make the water-guiding layer 1 inside;

[0074] b. Connect the laminated layers at one or both ends of the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com