Welding burr scraping structure

A burr and rough cutting technology, applied in the direction of welding fittings, etc., can solve the problems that the protrusions at the weld are easily corroded, the overall strength of the weld is reduced, and the service life of the steel pipe is reduced, so as to improve the cutting efficiency and increase the predictability. Effects of cleaning up and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

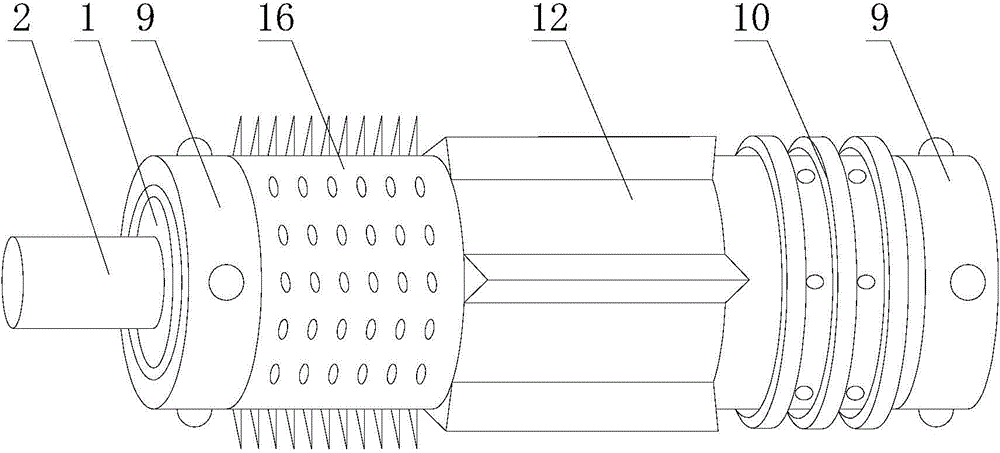

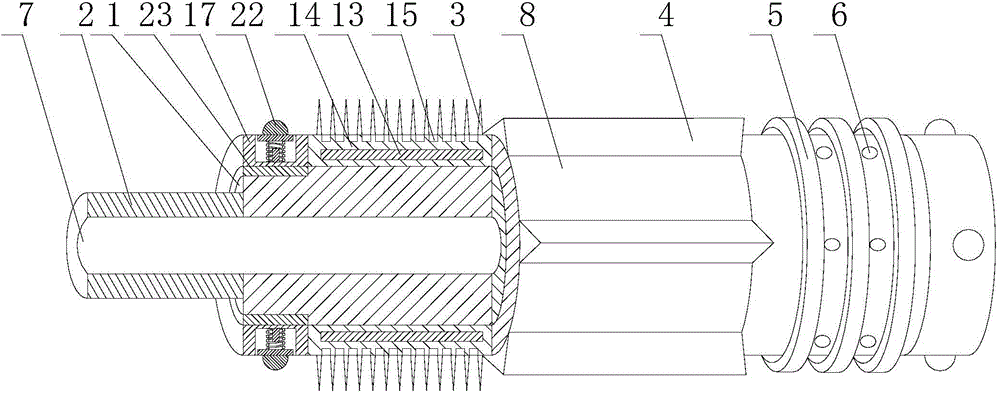

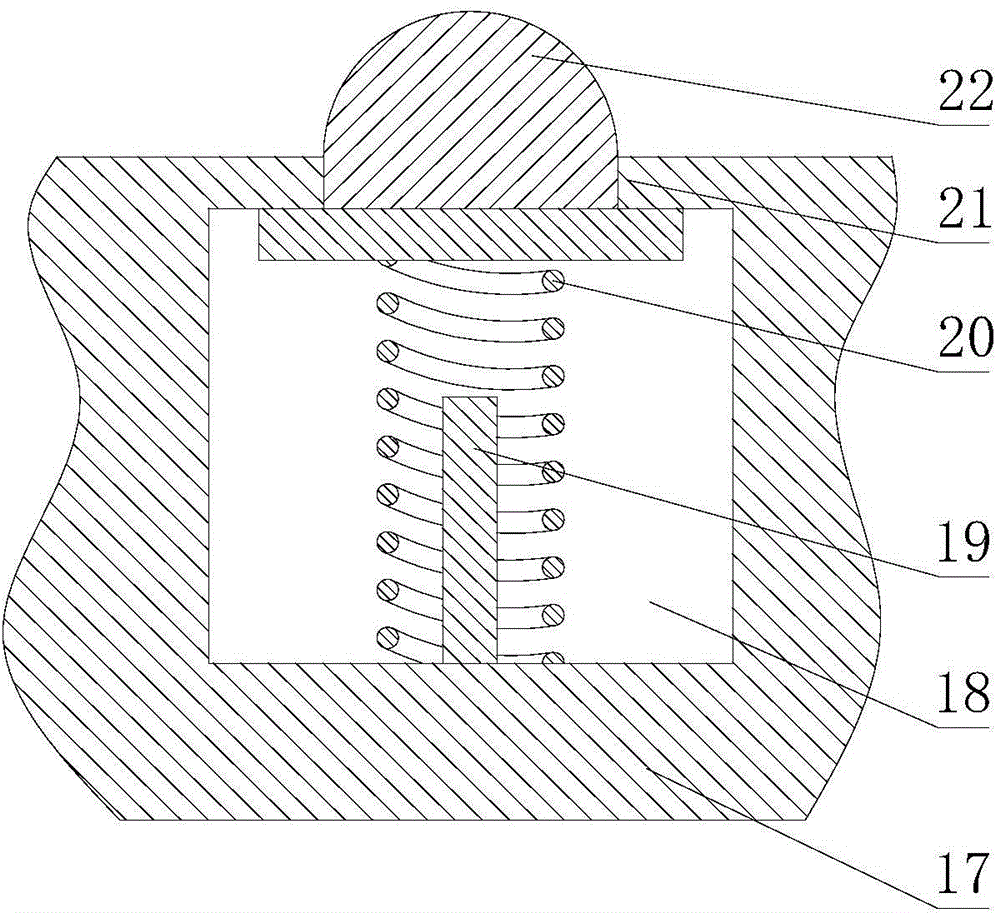

[0028] Such as Figure 1 to Figure 4As shown, the welding burr scraping structure includes a movable shaft 1 arranged horizontally and a connecting body 2 connected to the front end of the movable shaft 1 and arranged horizontally. The movable shaft 1 and the connecting body 2 are both hollow, and the two communicate with each other to form a water injection channel 7 , the front and rear sections of the movable shaft 1 are provided with a supporting part 9 through bearings 23, and the middle section of the movable shaft 1 is provided with a rough cutting part 10, a fine cutting part 12 and a cleaning part 16 successively from back to front; the rough cutting part 10 includes A plurality of annular retaining rings 5 are sleeved on the movable shaft 1 at intervals, and a plurality of discharge holes 6 communicating with the water injection channel 7 are arranged between two adjacent annular retaining rings 5; The annular knife seat 8 on the movable shaft 1, the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com