NOTE automatic association equipment

A technology of equipment and movable end, which is applied in the field of NOTE automatic concluding equipment, can solve problems such as unguaranteed associating accuracy, panel damage, unstable associating quality, etc., to ensure conjugation success rate and good product rate, reduce labor, and meet production needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

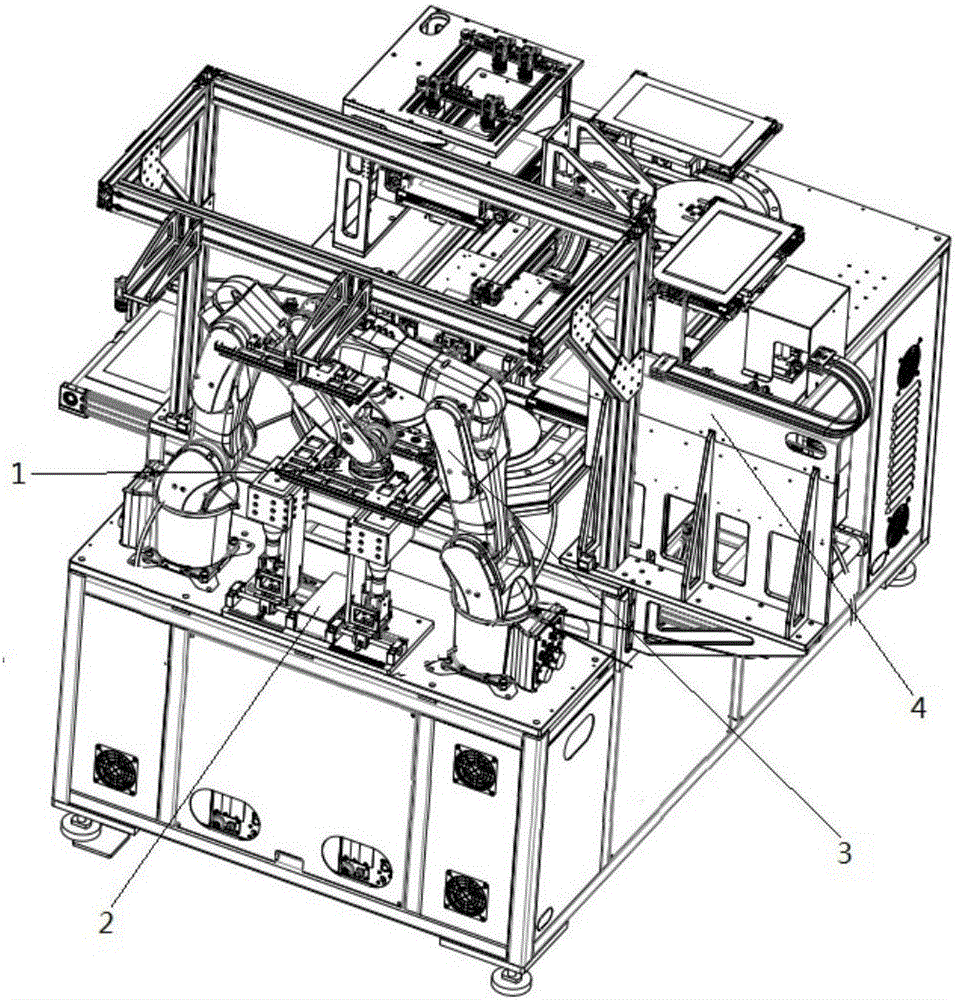

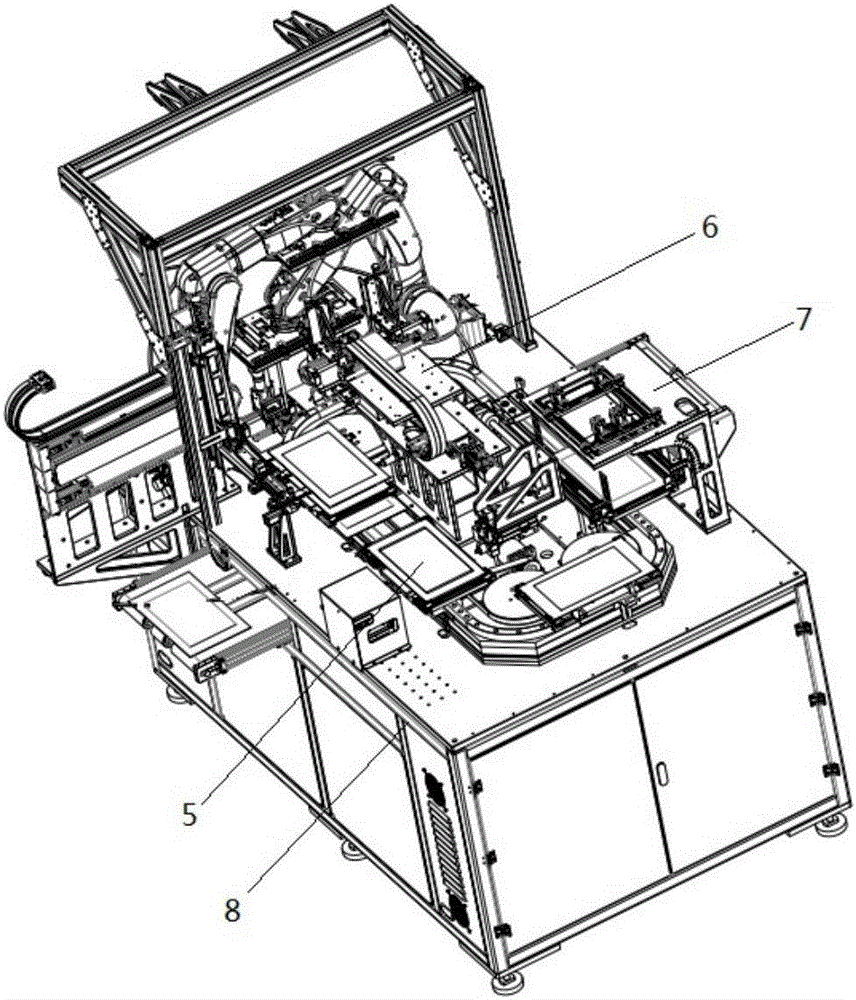

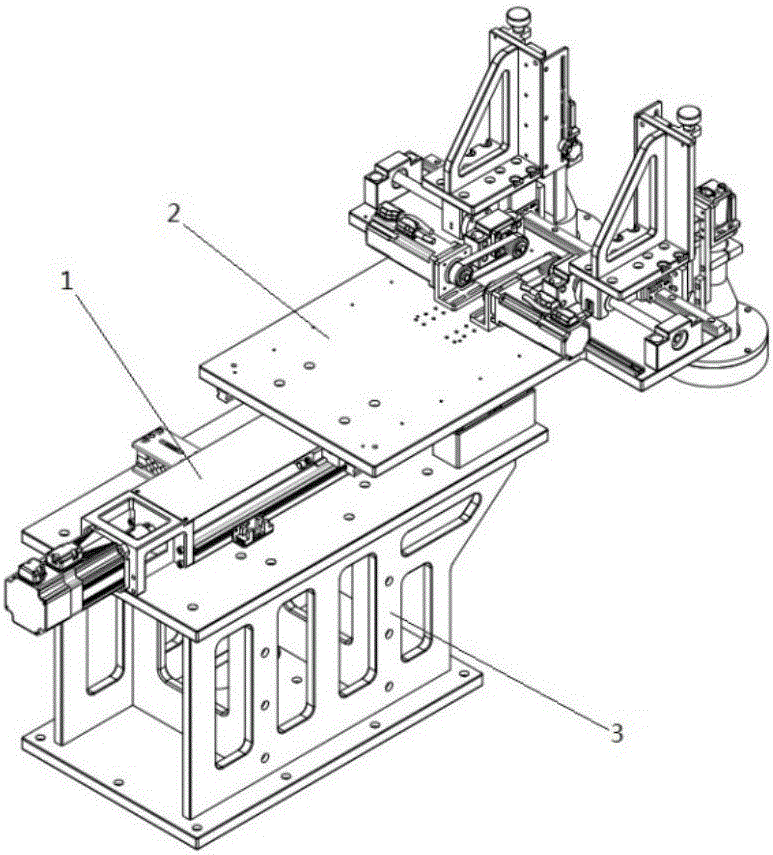

[0034] Such as figure 1As shown, this embodiment discloses a NOTE automatic concluding device, including a frame 7, on which an annular transmission track 9 is arranged, the transmission track includes an annular slide rail, and an annular slide rail is provided inside the annular slide rail. The rails are parallel to the conveyor belt, the conveyor belt is embedded on the guide wheel, one end of the carrier is nested on the slide rail, and the other end is fixed on the conveyor belt. At least six carriers 5 are fixed on the conveying track 9, and the carriers 5 correspond to the workstations arranged on the conveying track 9. The workstations are respectively the feeding station, the first temporary storage station, the positioning detection station, and the second The temporary storage station, the binding station, the discharging station, the transmission track 9 drives the carrier 5 to perform circular motion, the rotation distance of the transmission track 9 is equal to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com